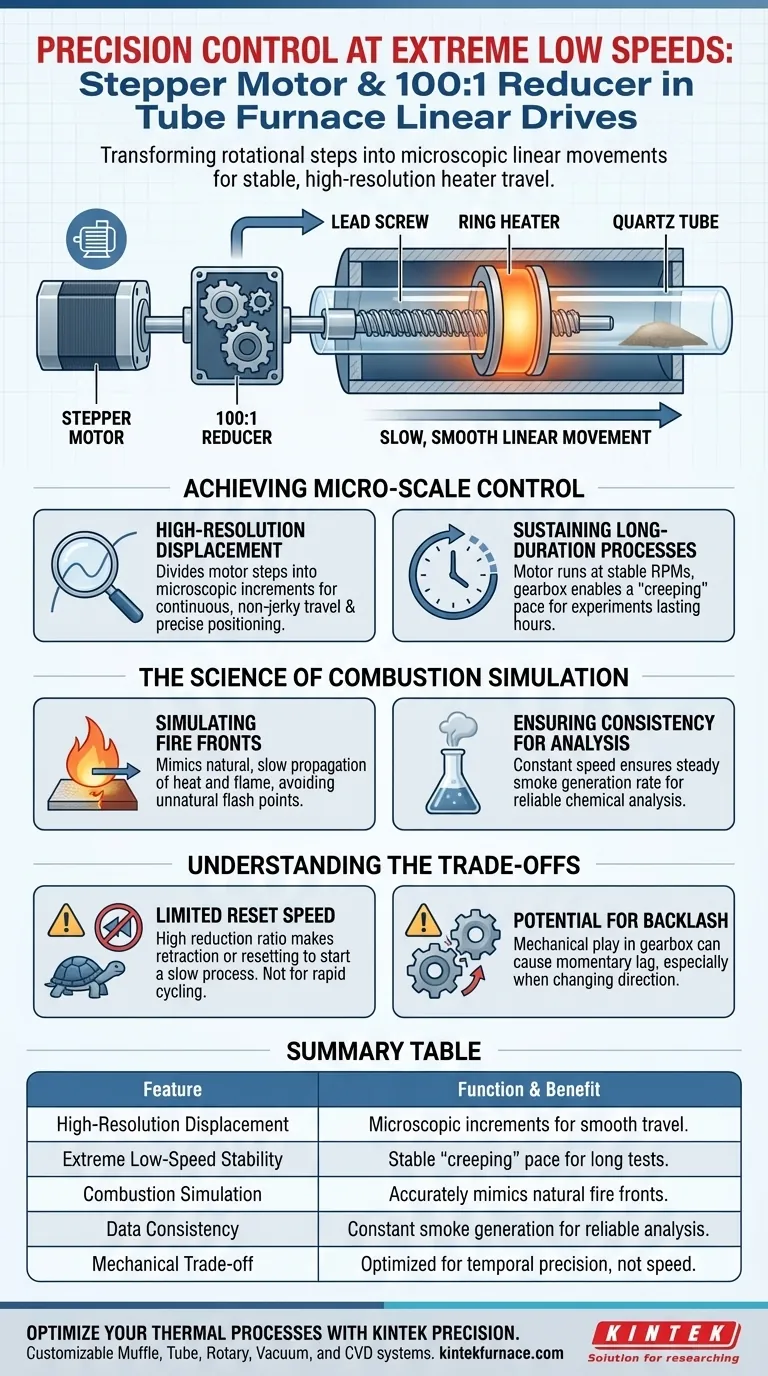

Precision control at extreme low speeds is the primary purpose of this configuration. By pairing a stepper motor with a high-ratio (100:1) reducer, the linear drive mechanism transforms standard rotational steps into microscopic linear movements, allowing the ring heater to travel along the quartz tube with exceptional stability and resolution.

The combination of a stepper motor and a 100:1 reducer is essential for temporal precision rather than raw power. It enables the physical simulation of slow-moving natural phenomena, such as advancing fire fronts, ensuring consistent combustion and smoke generation over extended periods.

Achieving Micro-Scale Control

High-Resolution Displacement

The core function of the 100:1 reducer is to divide the physical step of the motor into significantly smaller increments.

This ensures that the movement of the heater is not "stepped" or jerky, but effectively continuous. It allows for the precise positioning required to maintain a specific temperature gradient along the tube.

Sustaining Long-Duration Processes

Combustion experiments in laboratory settings often require observation periods ranging from minutes to several hours.

Direct-drive motors struggle to maintain smooth rotation at the extremely low RPMs required for these durations. The reducer allows the motor to spin at a stable speed while the output shaft moves the heater at the necessary "creeping" pace.

The Science of Combustion Simulation

Simulating Fire Fronts

To gather accurate data, the furnace must replicate how fire naturally advances through a material.

This drive mechanism simulates a "creeping" fire front. By moving the heater slowly, the system mimics the natural propagation of heat and flame, rather than subjecting the sample to an instant, unnatural flash point.

Ensuring Consistency for Analysis

Reliable laboratory analysis depends on the consistent generation of smoke and combustion byproducts.

Any fluctuation in the heater's speed would alter the rate of combustion, leading to inconsistent data. The high gear reduction mitigates mechanical variances, ensuring the smoke generation rate remains constant for valid chemical analysis.

Understanding the Trade-offs

Limited Reset Speed

The 100:1 reduction ratio that enables precision acts as a bottleneck for rapid movement.

Retracting the heater or resetting the mechanism to the starting position is a slow process. This configuration is ill-suited for experiments requiring rapid cycling or fast positional adjustments.

Potential for Backlash

While the reducer increases resolution, gearboxes introduce the possibility of mechanical play, known as backlash.

In ultra-precise applications, this play can result in a momentary lag between the motor starting and the heater moving. While generally negligible for continuous unidirectional movement, it must be accounted for if the direction changes.

Making the Right Choice for Your Goal

This mechanism is a specialized tool designed for specific experimental parameters. Here is how to view its utility:

- If your primary focus is accurate simulation: Rely on this high-reduction setup to mimic the natural, slow timescale of environmental combustion.

- If your primary focus is data consistency: Trust the reducer to smooth out motor pulses, providing the steady-state smoke generation required for sensitive analyzers.

Ultimately, this geared assembly serves as the critical bridge between mechanical rotation and the organic timeline of natural combustion.

Summary Table:

| Feature | Function & Benefit |

|---|---|

| High-Resolution Displacement | Converts motor steps into microscopic linear increments for smooth, continuous travel. |

| Extreme Low-Speed Stability | Allows the motor to run at stable RPMs while achieving a "creeping" pace for long-duration tests. |

| Combustion Simulation | Accurately mimics natural fire front propagation for realistic thermal gradients. |

| Data Consistency | Ensures a constant rate of smoke generation and byproducts for reliable chemical analysis. |

| Mechanical Trade-off | Optimized for temporal precision over raw speed; best suited for unidirectional movement. |

Optimize Your Thermal Processes with KINTEK Precision

Precise control is the difference between a successful simulation and inconsistent data. At KINTEK, we specialize in high-performance thermal solutions designed for the most demanding research environments. Backed by expert R&D and world-class manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet your specific linear drive and temperature gradient requirements.

Whether you need ultra-low speed stability for combustion research or high-temperature uniformity for material synthesis, our engineers are ready to tailor a system for your unique needs. Contact us today to discuss your project and see how KINTEK’s advanced laboratory furnaces can elevate your experimental accuracy.

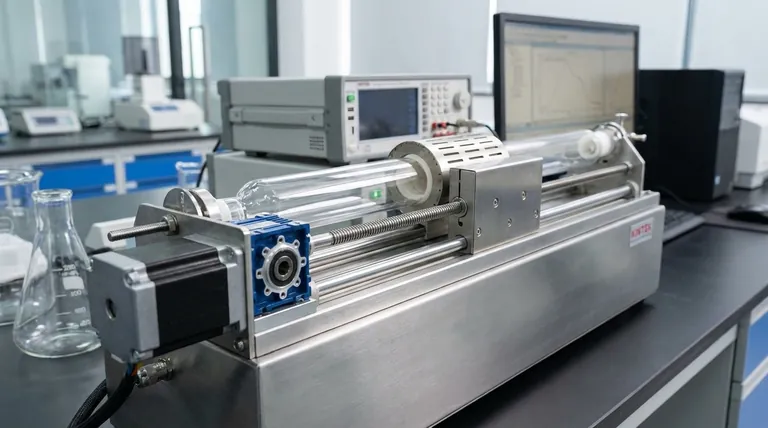

Visual Guide

References

- Casey Coffland, Elliott T. Gall. An open-source linear actuated-quartz tube furnace with programmable ceramic heater movement for laboratory-scale studies of combustion and emission. DOI: 10.2139/ssrn.5687995

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- How does the heating mechanism differ between vertical and horizontal tube furnaces? Optimize Your Lab's Thermal Processing

- What role does a high-temperature Tube Furnace play in ScSZ thin film post-treatment? Master Structural Refinement

- How does a vertical tube furnace comply with environmental standards? Achieve Eco-Friendly and Efficient Lab Operations

- What critical conditions does a tube furnace provide for Cu-Fe-NC-3 pyrolysis? Achieve Precision Catalyst Synthesis

- What are the key features of temperature control in a vacuum tube furnace? Achieve Precision Heating for Advanced Materials

- At what pressures can gases be introduced into the 3-Zone tube furnace? Optimize Your Thermal Process Control

- How does a high-temperature tube furnace facilitate sulfur melt-diffusion? Precision Heating for PCFC/S Cathodes

- Why is it necessary to use a tube furnace with an inert atmosphere for the thermal debinding of ceramic green bodies?