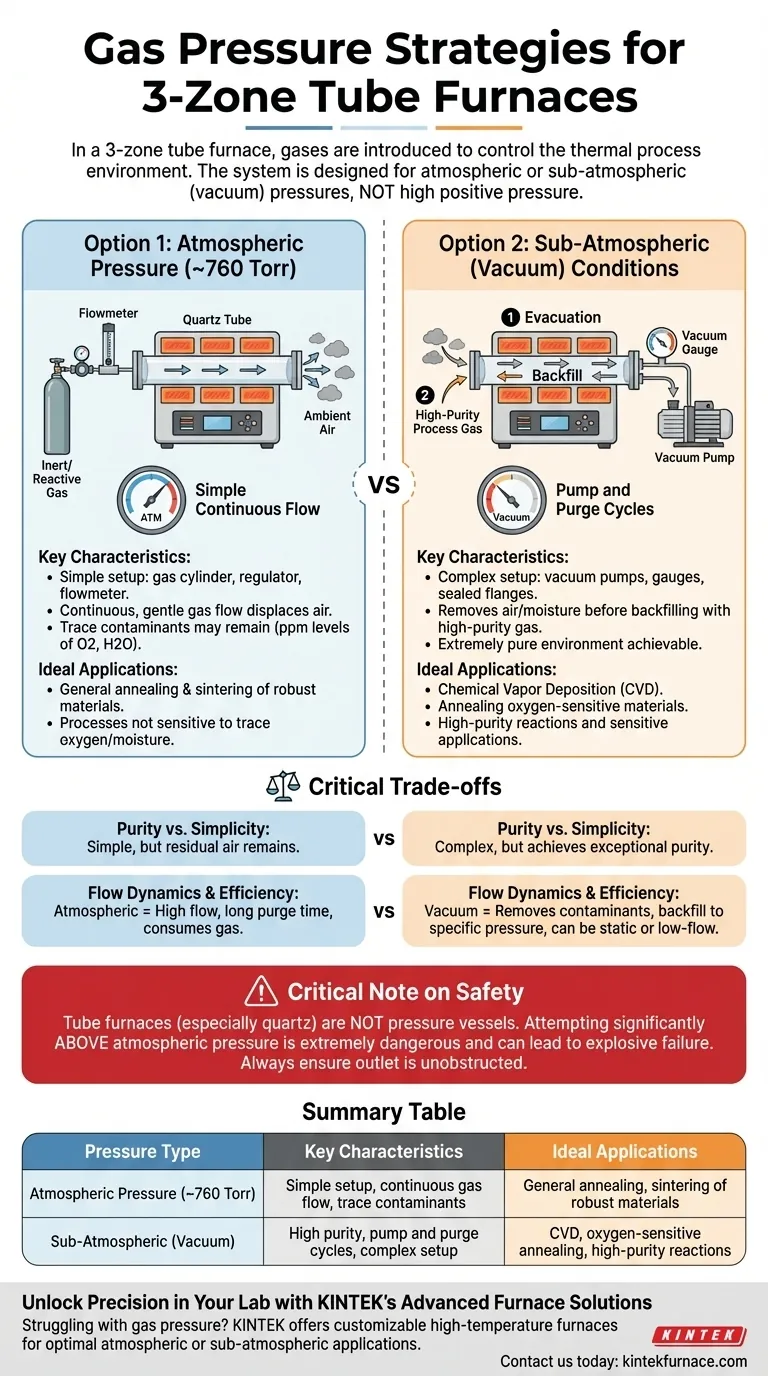

In a 3-zone tube furnace, gases can be introduced into the process tube at either atmospheric pressure or sub-atmospheric (vacuum) pressures. The system is designed to control a thermal process within a specific gaseous environment, not to contain high pressure.

The choice between atmospheric and sub-atmospheric pressure is not a limitation of the furnace itself, but a critical decision about process control. Your primary goal dictates the pressure strategy: atmospheric pressure offers simplicity, while sub-atmospheric conditions provide a higher degree of purity and environmental control.

The Role of Pressure in Your Process

The pressure inside the tube furnace directly defines the chemical environment for your sample. It determines the purity of the atmosphere, the concentration of reactive gases, and the efficiency of removing unwanted contaminants.

Option 1: Atmospheric Pressure

Operating at atmospheric pressure (approximately 760 Torr or 1 atm) is the most straightforward method for creating a controlled environment.

This involves flowing an inert or reactive gas through the tube to displace the ambient air. A continuous, gentle flow is maintained throughout the process to prevent air from diffusing back into the system.

This method is suitable for processes that are not critically sensitive to trace amounts of oxygen or moisture, such as general annealing or sintering of robust materials.

Option 2: Sub-Atmospheric (Vacuum) Conditions

Operating at sub-atmospheric pressures requires a vacuum system to first evacuate the air and moisture from the process tube.

Once a desired vacuum level is reached, the tube is backfilled with the high-purity process gas. This "pump and purge" cycle can be repeated multiple times to achieve an extremely pure environment, far exceeding what is possible with atmospheric purging alone.

This approach is essential for sensitive applications like Chemical Vapor Deposition (CVD), annealing oxygen-sensitive materials, or any process where atmospheric contaminants could compromise the results.

Understanding the Critical Trade-offs

Choosing a pressure strategy involves balancing process requirements with operational complexity and safety. The most common mistake is failing to recognize that these furnaces are not designed for positive pressure.

Purity vs. Simplicity

An atmospheric purge is simple, requiring only a gas cylinder, regulator, and flowmeter. However, it is nearly impossible to remove all residual air, leaving behind parts-per-million levels of oxygen and water vapor.

A sub-atmospheric pump-down and backfill process is more complex, requiring vacuum pumps, gauges, and sealed flanges. The benefit is an exceptionally pure environment, critical for high-performance materials and sensitive chemical reactions.

Flow Dynamics and Efficiency

At atmospheric pressure, you rely on a high flow rate and a long purge time to displace ambient air, which can consume a significant amount of expensive gas.

Under vacuum, you physically remove contaminants first. This allows you to backfill with your process gas to a specific, often low, pressure, creating a controlled, static environment or a low-flow one, which can be more efficient for certain reactions.

A Critical Note on Safety

Tube furnaces, particularly those with quartz tubes, are not pressure vessels. Attempting to introduce gas at pressures significantly above atmospheric pressure is extremely dangerous and can lead to explosive failure of the tube. Always ensure your outlet is unobstructed to prevent accidental pressure buildup.

Making the Right Choice for Your Goal

Select your gas introduction strategy based on the specific requirements of your experiment.

- If your primary focus is a simple inert environment for a robust process: Use a continuous, low-flow purge of inert gas at atmospheric pressure.

- If your primary focus is ultimate purity for a sensitive material or reaction: Use a vacuum pump to evacuate the tube before backfilling with high-purity gas to the desired sub-atmospheric or atmospheric pressure.

- If your primary focus is removing moisture or volatile byproducts during a process: Operate under a slight vacuum or a low-pressure flow to actively pull contaminants away from your sample.

By matching the pressure conditions to your material and process goals, you gain precise control over your experimental outcome.

Summary Table:

| Pressure Type | Key Characteristics | Ideal Applications |

|---|---|---|

| Atmospheric Pressure (~760 Torr) | Simple setup, continuous gas flow, may have trace contaminants | General annealing, sintering of robust materials |

| Sub-Atmospheric (Vacuum) | High purity, pump and purge cycles, complex setup | CVD, oxygen-sensitive annealing, high-purity reactions |

Unlock Precision in Your Lab with KINTEK's Advanced Furnace Solutions

Struggling to achieve the right gas pressure for your thermal processes? KINTEK specializes in high-temperature furnaces tailored to your unique needs. Our Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems come with deep customization capabilities, ensuring optimal performance for atmospheric or sub-atmospheric applications. Whether you're handling sensitive materials or need robust process control, we deliver reliable, safe, and efficient solutions.

Contact us today via our contact form to discuss how our expertise can enhance your experimental outcomes and drive innovation in your laboratory!

Visual Guide

Related Products

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the basic construction of a rotary tube furnace? Key Components for Uniform Heating

- What factors should be considered when selecting a tube for a rotary tube furnace? Ensure Optimal Performance and Longevity

- What are some industrial applications of rotary tube furnaces? Boost Your Material Processing Efficiency

- What are the key components of a rotary tube furnace? Essential Parts for Uniform Heating

- What types of materials can be processed in a rotary tube furnace? Discover Ideal Materials for High-Temp Processing