At its core, a split tube furnace offers one critical advantage over its standard counterparts: operational flexibility. While all tube furnaces provide a controlled, high-temperature environment, the split tube design features a chamber that hinges open into two halves. This allows for direct, convenient access to the sample and work tube, dramatically simplifying the loading and unloading process, especially for complex experimental setups.

The decision to use a split tube furnace is not about achieving better temperatures or atmospheres, but about optimizing your workflow. Its primary benefit is logistical convenience, which translates into reduced downtime and the ability to run experiments that are physically impossible in a standard, solid-tube furnace.

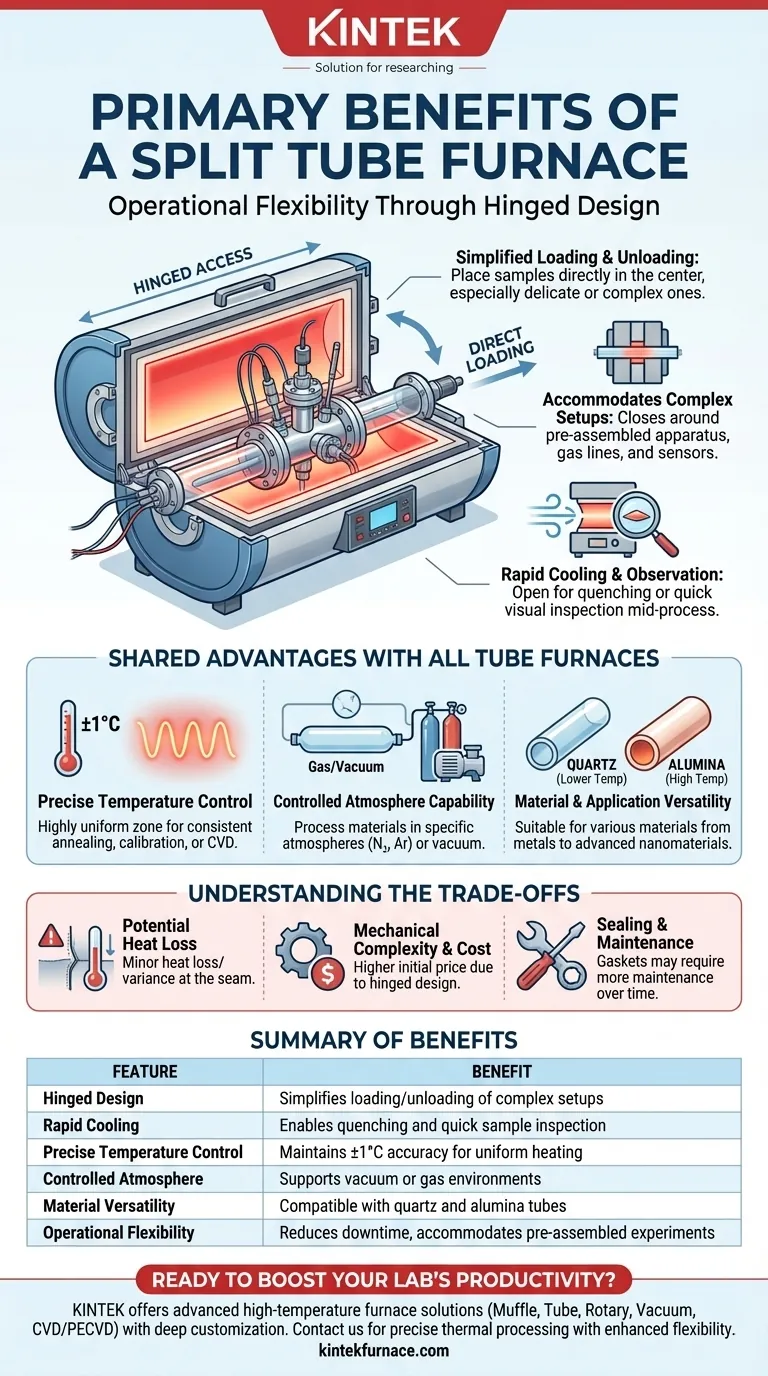

The Defining Feature: Unparalleled Access

The hinged body is the single feature that separates a split tube furnace from a conventional one. This design directly addresses several common laboratory challenges.

Simplified Sample Loading and Unloading

Instead of carefully sliding a sample crucible or substrate down a long, narrow tube, a split tube furnace allows you to place it directly into the center of the heating zone. This is invaluable when working with delicate samples or when precise positioning is critical from the start.

Accommodating Complex Setups

The most significant use case is for samples that are part of a larger, pre-assembled apparatus. If your work tube has fixed flanges, multiple gas lines, or sensor feedthroughs, it often cannot be inserted into a standard furnace. A split tube furnace closes around this existing setup, making it the only viable option for many in-situ experiments.

Enabling Rapid Cooling and Observation

The ability to open the furnace provides a mechanism for rapid cooling (quenching) by exposing the work tube to ambient air. In a standard furnace, the sample must cool down with the furnace insulation, a much slower process. This feature also allows for quick visual inspection of the sample mid-process.

Shared Advantages with All Tube Furnaces

By choosing a split tube design, you do not sacrifice the fundamental benefits that make tube furnaces essential for thermal processing. It inherits all the core capabilities of its non-split counterparts.

Precise and Uniform Temperature Control

Like all modern tube furnaces, split models offer exceptional temperature accuracy, often with control to within ±1°C. They are designed to create a highly uniform temperature zone in the center of the tube, which is critical for processes like annealing, calibration, or chemical vapor deposition (CVD) that demand consistency.

Controlled Atmosphere Capability

The work tube within the furnace can be sealed and connected to gas or vacuum systems. This allows you to process materials in a specific atmosphere (like nitrogen or argon to prevent oxidation) or under vacuum, making them highly versatile for materials science and chemistry applications.

Material and Application Versatility

Split tube furnaces can accommodate work tubes made from various materials, such as quartz for lower temperatures or alumina for high-temperature applications (up to 1200°C or more, depending on the model). This makes them suitable for processing everything from metals and ceramics to advanced nanomaterials.

Understanding the Trade-offs

While the benefits are significant, the split design introduces complexities that are important to consider.

Potential for Heat Loss

The seam where the two furnace halves meet can be a source of minor heat loss and can create a slight temperature variance compared to the perfect uniformity of a solid, one-piece furnace body. Modern designs use high-quality insulation and overlapping edges to minimize this, but it is an inherent physical characteristic.

Mechanical Complexity and Cost

A hinged, multi-part furnace is more complex to manufacture than a simple, solid cylinder. This added mechanical complexity and the required precision engineering generally result in a higher initial purchase price compared to a non-split furnace of the same size and temperature rating.

Sealing and Maintenance

While the work tube itself is sealed for atmosphere control, the furnace body's seal is for thermal efficiency. Over time, the gaskets and insulating surfaces where the halves meet may require more maintenance to ensure a tight fit and prevent heat leakage compared to a solid-body furnace.

Choosing the Right Furnace for Your Application

Your final decision should be guided by the specific demands of your process workflow.

- If your primary focus is operational speed and flexibility: Choose a split tube furnace. It is ideal for labs with high sample throughput or for experiments with intricate, pre-assembled reactors that cannot be inserted into a fixed tube.

- If your primary focus is budget optimization and process simplicity: A standard, non-split tube furnace is often more cost-effective and sufficient. It excels in established, repeatable processes where samples are easily loaded from the ends.

Ultimately, selecting the right furnace depends on a clear assessment of your experimental workflow and logistical requirements.

Summary Table:

| Feature | Benefit |

|---|---|

| Hinged Design | Simplifies loading/unloading of complex setups |

| Rapid Cooling | Enables quenching and quick sample inspection |

| Precise Temperature Control | Maintains ±1°C accuracy for uniform heating |

| Controlled Atmosphere | Supports vacuum or gas environments for oxidation prevention |

| Material Versatility | Compatible with quartz and alumina tubes for various applications |

| Operational Flexibility | Reduces downtime and accommodates pre-assembled experiments |

Ready to boost your lab's productivity with a customized split tube furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your unique needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities. Whether you're in materials science, chemistry, or research, we can help you achieve precise thermal processing with enhanced flexibility. Contact us today to discuss how we can support your experimental goals!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- How do vertical tube furnaces comply with environmental standards? A Guide to Clean, Efficient Operation

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency