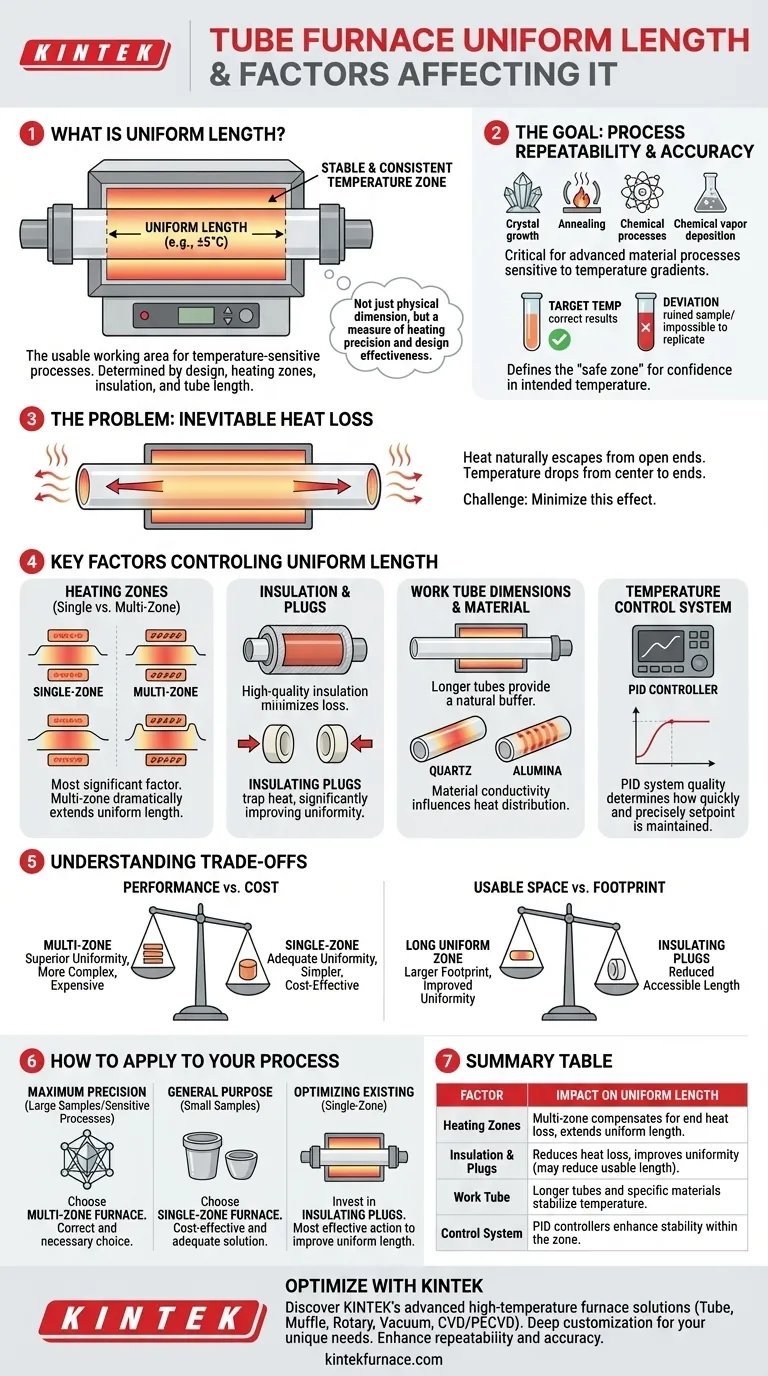

In simple terms, the uniform length of a tube furnace is the central region inside the furnace tube where the temperature is the most stable and consistent. This zone, often specified with a tolerance like ±5°C, is the usable working area for temperature-sensitive processes. Its length is not fixed but is a critical performance characteristic determined by the furnace's design, including its heating zones, insulation, and the length of the work tube.

The concept of "uniform length" is central to understanding a tube furnace's value. It isn't merely a physical dimension but a measure of its heating precision, directly determined by how effectively the design counteracts natural heat loss at the tube's ends.

Why Uniform Length is the Critical Metric

A tube furnace's primary purpose is to provide an extremely controlled and stable thermal environment. The quality of your results, whether in a research lab or an industrial production line, depends directly on this stability.

The Goal: Process Repeatability and Accuracy

Many advanced material processes, such as crystal growth, annealing, and chemical vapor deposition, are highly sensitive to temperature gradients.

Even a small deviation from the target temperature can alter material properties, ruin a sample, or make experimental results impossible to replicate. The uniform length defines the "safe zone" where you can be confident your sample is experiencing the intended temperature.

The Problem: Inevitable Heat Loss

Heat naturally escapes from any open end of the furnace tube. This physical reality means the temperature will inevitably drop off as you move from the center of the furnace towards its ends.

The entire engineering challenge of a high-performance tube furnace is to minimize this effect and maximize the length of the stable central zone.

Key Factors That Control Uniform Length

Achieving a long and stable uniform zone is a matter of intelligent heat management. Several design factors work together to accomplish this.

Heating Zones: Single vs. Multi-Zone

This is the most significant factor. A single-zone furnace has one set of heating elements and one controller. It is simpler but will always have a pronounced temperature drop-off at the ends.

A multi-zone furnace (typically three zones) has separate heating elements and controllers for the center and the two end zones. By setting the end zones to a slightly higher temperature, they can actively compensate for heat loss, dramatically extending the length of the uniform central zone.

Insulation and Insulating Plugs

High-quality insulation within the furnace body minimizes heat loss to the surrounding environment.

More importantly, insulating plugs made of ceramic fiber can be inserted into the ends of the work tube. These act as direct thermal barriers, physically trapping heat and significantly improving temperature uniformity.

Work Tube Dimensions and Material

A longer work tube that extends well beyond the heated length of the furnace provides a natural buffer, which can help stabilize the temperature profile.

The tube material, such as quartz or alumina, also has different thermal conductivity properties that can subtly influence the heat distribution.

Temperature Control System

Modern furnaces use a PID (Proportional-Integral-Derivative) controller. The quality and tuning of this system determine how quickly and precisely it can maintain the setpoint temperature, contributing to the stability within the uniform zone.

Understanding the Trade-offs

Choosing or configuring a furnace involves balancing performance needs with practical constraints.

Performance vs. Cost

A multi-zone furnace offers vastly superior temperature uniformity over a longer length, but it is more complex, with additional controllers and power electronics, making it significantly more expensive than a single-zone model.

Usable Space vs. Furnace Footprint

Achieving a long uniform zone often requires a physically longer heated length and a longer work tube. This increases the overall footprint of the equipment in the lab.

Furthermore, using insulating plugs improves uniformity but reduces the physically accessible length inside the tube for loading and unloading samples.

How to Apply This to Your Process

Your specific application dictates the level of uniformity you require.

- If your primary focus is maximum precision for large samples or sensitive processes: A multi-zone furnace is the correct and necessary choice.

- If your primary focus is general-purpose heating of small samples: A well-designed single-zone furnace is often a cost-effective and perfectly adequate solution.

- If your primary focus is optimizing an existing single-zone furnace: Investing in high-quality insulating plugs is the single most effective action you can take to improve your uniform length.

Ultimately, understanding these factors empowers you to select the right equipment and operate it to achieve the most reliable and repeatable results.

Summary Table:

| Factor | Impact on Uniform Length |

|---|---|

| Heating Zones (Single vs. Multi-Zone) | Multi-zone extends uniform length by compensating for heat loss at ends |

| Insulation and Insulating Plugs | Improves uniformity by reducing heat loss, but may reduce accessible tube length |

| Work Tube Dimensions and Material | Longer tubes and materials like quartz/alumina can stabilize temperature |

| Temperature Control System | PID controllers enhance stability within the uniform zone |

Optimize your laboratory's thermal processes with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with reliable equipment like Tube Furnaces, Muffle Furnaces, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, enhancing repeatability and accuracy. Contact us today to discuss how we can support your specific requirements and drive your research forward!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability