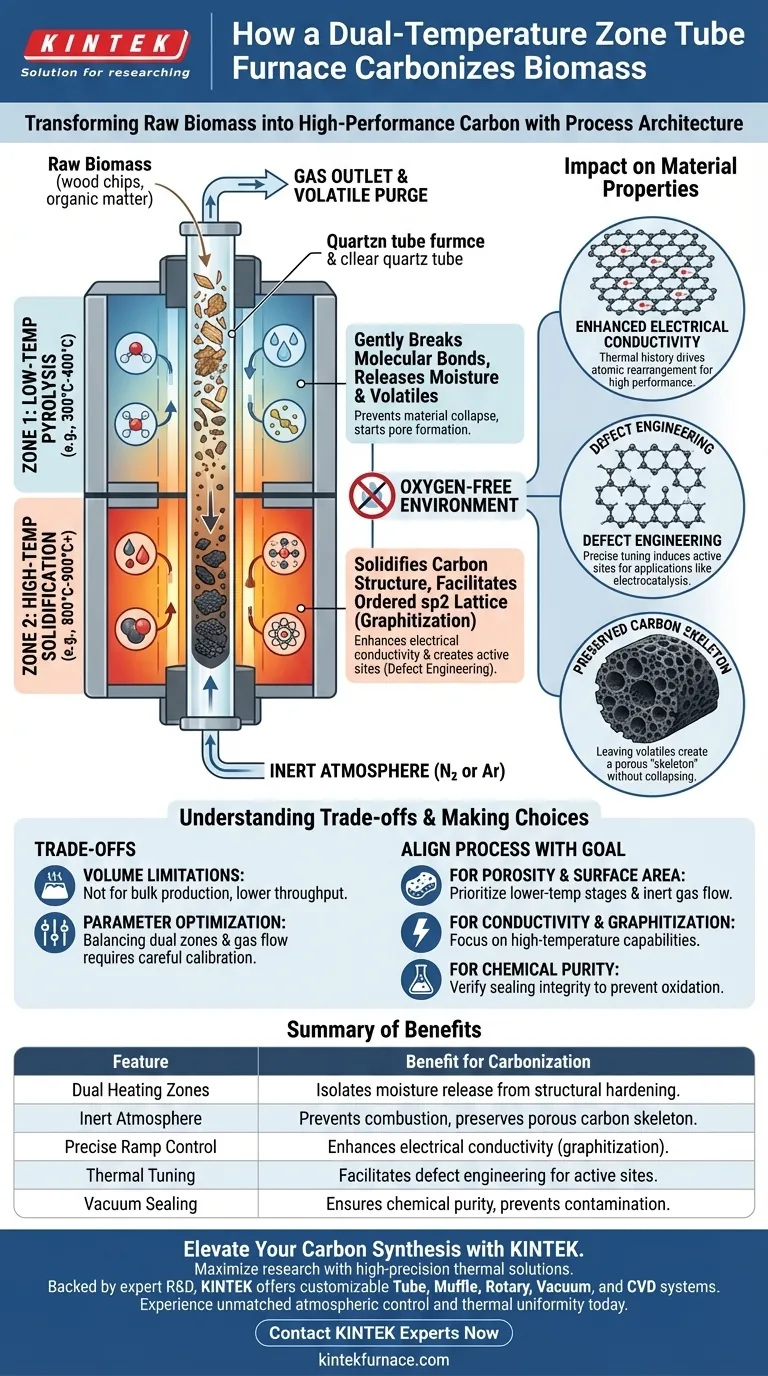

A dual-temperature zone tube furnace is the pivotal instrument for transforming raw biomass into structured, high-performance carbon materials. It functions by providing a strictly controlled, oxygen-free environment where multi-stage thermal processing can occur simultaneously or sequentially. By establishing distinct temperature gradients, it enables specific pyrolysis reactions to take place at exact intervals, preventing the biomass from burning into ash and instead converting it into a stable carbon skeleton.

Core Takeaway While standard furnaces offer heat, a dual-temperature zone furnace offers process architecture. Its ability to run multi-stage heating curves allows for the precise separation of volatile release and structural hardening, ensuring the final carbon material possesses the desired porosity and conductivity.

The Mechanics of Multi-Stage Carbonization

Enabling Complex Heating Curves

The defining feature of this equipment is the ability to create and control two separate temperature zones within the same tube.

This allows researchers to design multi-stage heating curves that single-zone furnaces cannot replicate. You can subject the biomass to a specific temperature profile as it moves through the tube, or hold different parts of the sample at different temperatures to study gradient effects.

Isolating Pyrolysis Reactions

Biomass carbonization involves various chemical breakdown phases.

The dual-zone configuration allows you to target specific pyrolysis reactions in different zones. For example, one zone can be set to a lower temperature to gently break molecular bonds and release moisture, while the second zone operates at a higher temperature to solidify the carbon structure.

Atmospheric Control and Chemical Purity

Guaranteeing an Oxygen-Free Environment

Carbonization requires heat without combustion. If oxygen is present, biomass simply burns away.

The tube furnace utilizes superior sealing mechanisms to maintain a high-purity inert atmosphere. By continuously purging the tube with inert gases like nitrogen (N2) or Argon (Ar), the system prevents oxidative side reactions that would destroy the material or introduce impurities.

Preserving the Carbon Skeleton

The inert atmosphere is critical for the physical structure of the material.

As the furnace heats the biomass (often between 300°C and 900°C depending on the stage), organic volatiles are driven off. Because oxidation is prevented, these leaving volatiles create a porous "skeleton" rather than causing the material to collapse, effectively setting the stage for high surface area and structural stability.

Impact on Material Properties

Enhancing Electrical Conductivity

For applications requiring conductive materials, such as electrode manufacturing, thermal history is vital.

High-temperature treatment within the tube furnace facilitates the rearrangement of carbon atoms. This process, often involving deep deoxygenation, helps form a highly ordered sp2 hybridized lattice (graphitization), creating the conductive paths necessary for electronic performance.

Defect Engineering

Beyond basic carbonization, the furnace environment can be tuned to enhance electrochemical activity.

Precise thermal treatment can induce specific carbon vacancy defects within the material structure. These defects are not errors; they often serve as active sites that significantly increase performance in applications like electrocatalytic chlorine evolution.

Understanding the Trade-offs

Volume Limitations

Tube furnaces are inherently limited by the diameter of the tube.

While they offer unmatched control for research and high-value material synthesis, they are not designed for bulk production. The throughput is significantly lower than that of industrial rotary kilns or large box furnaces.

Complexity of Parameter Optimization

With dual zones come more variables.

Balancing gas flow rates, temperature ramp speeds, and the interaction between the two temperature zones requires careful calibration. An incorrect thermal gradient between zones can lead to uneven carbonization or thermal shock to the ceramic tube.

Making the Right Choice for Your Goal

To maximize the utility of a dual-temperature zone tube furnace, align your process with your specific material objectives:

- If your primary focus is Porosity and Surface Area: Prioritize the inert gas flow and lower-temperature stages (300°C–400°C) to ensure volatile components are removed slowly without collapsing the pore structure.

- If your primary focus is Conductivity and Graphitization: Focus on the high-temperature capabilities (800°C+) to drive the atomic rearrangement into an ordered sp2 lattice.

- If your primary focus is Chemical Purity: Ensure the sealing integrity is verified before every run to prevent even trace amounts of oxygen from causing oxidation side reactions.

The dual-temperature zone furnace transforms carbonization from a crude burning process into a precise act of chemical engineering.

Summary Table:

| Feature | Benefit for Biomass Carbonization |

|---|---|

| Dual Heating Zones | Creates complex thermal gradients to isolate moisture release from structural hardening. |

| Inert Atmosphere | Prevents combustion and oxidation, preserving the porous carbon skeleton. |

| Precise Ramp Control | Enhances electrical conductivity through ordered sp2 lattice formation (graphitization). |

| Thermal Tuning | Facilitates defect engineering to create active sites for electrocatalytic applications. |

| Vacuum Sealing | Ensures chemical purity by purging volatiles and preventing atmospheric contamination. |

Elevate Your Carbon Synthesis with KINTEK

Maximize your research potential with high-precision thermal solutions. Backed by expert R&D and world-class manufacturing, KINTEK offers a comprehensive range of Tube, Muffle, Rotary, Vacuum, and CVD systems.

Whether you are engineering high-surface-area catalysts or conductive carbon electrodes, our lab high-temperature furnaces are fully customizable to meet your unique biomass processing needs. Experience unmatched atmospheric control and thermal uniformity today.

Visual Guide

References

- Tiantian Qi, Quanyuan Wei. The Effect of Corn Stover Carbon-Based Bimetallic Catalysts on the Depolarization Electrolysis Reaction of Sulfur Dioxide for Hydrogen Production. DOI: 10.3390/catal15010093

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- Why is a controlled atmosphere tube furnace essential for YBCO? Master Oxygen Stoichiometry for Superconductivity

- How does a high-temperature tube furnace facilitate the sintering process of modified graphite felt? Precision Control

- What role does a tube furnace play in tantalum capacitor recycling? Enhancing Metal Recovery Through Pyrolysis

- What role does a tube furnace play in converting nickel precursors? Master Thermal Reduction in Argon Atmospheres

- Why is it necessary to introduce high-purity nitrogen during tube furnace calcination? Ensure High-Performance La-EPS-C-450

- How does a tube furnace achieve high thermal efficiency? Optimize Energy Use for Cost Savings

- How does tube furnace cracking compare to fuel furnaces in terms of efficiency? Discover Higher Efficiency and Precision

- How does a high-temperature tube atmosphere furnace contribute to nitrogen-doping of graphene oxide? Enhance Your R&D