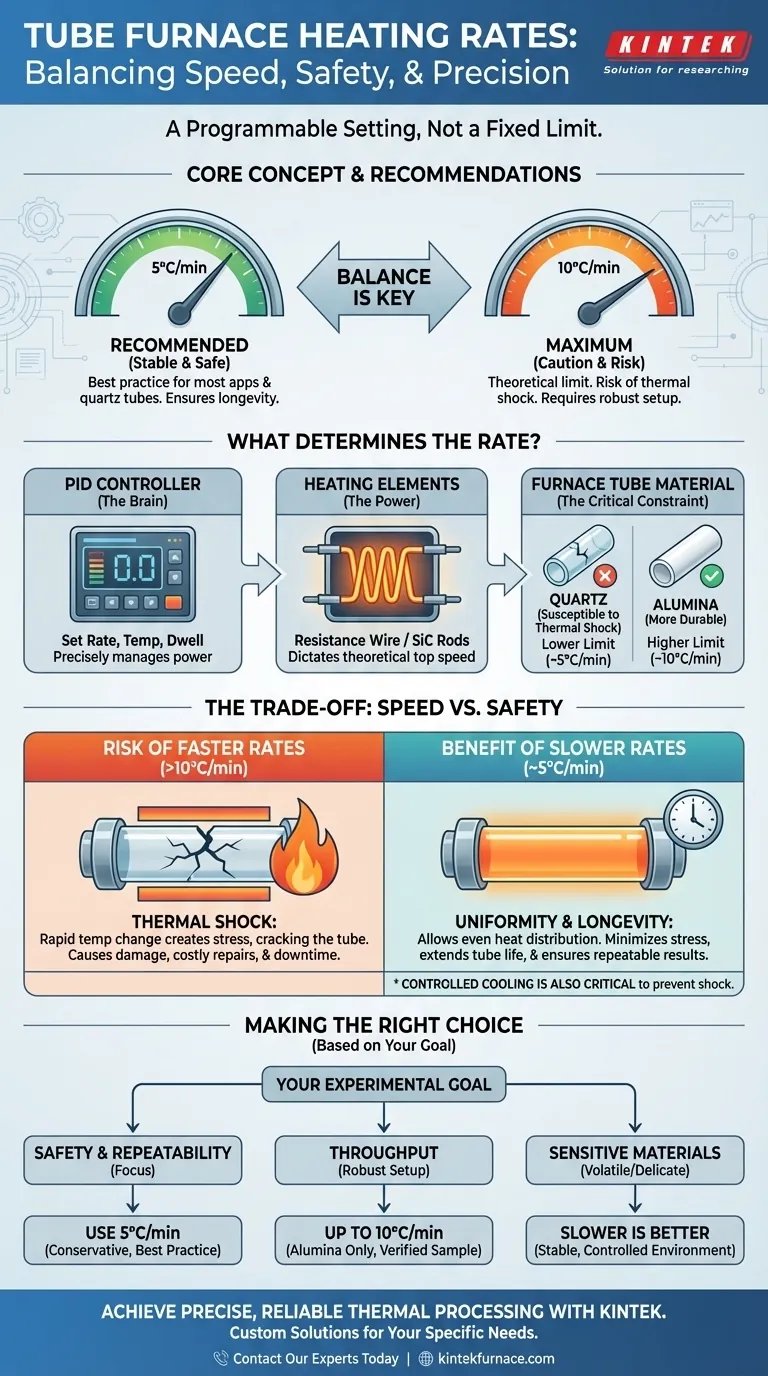

In practice, a standard tube furnace heating rate should not exceed 10°C per minute. For most applications, a more conservative rate of 5°C per minute is recommended to ensure thermal stability and prevent damage to the equipment. This rate is not a fixed physical limit but a crucial operational parameter you control to balance speed with safety and accuracy.

The heating rate of a tube furnace is a programmable setting, not an inherent property. The ideal rate is a trade-off between process speed and the physical limitations of the furnace components, primarily the risk of thermal shock to the furnace tube.

What Determines the Heating Rate?

The rate at which you can safely and effectively heat your sample is governed by the interplay of several key components. Understanding these parts reveals why the recommended limits exist.

The Temperature Control System

Modern tube furnaces use a PID (Proportional-Integral-Derivative) controller, which is the brain of the operation. This is where you program your desired heating rate, target temperature, and dwell time. The controller precisely manages power to the heating elements to follow your instructions accurately.

The Heating Elements

These components, often made of resistance wire or silicon carbide rods, are what actually generate the heat. Their maximum power output dictates the theoretical top speed at which the furnace chamber can be heated. However, using this maximum capability is rarely advisable.

The Furnace Tube Material

This is the most critical constraint. The tube, which holds your sample, is typically made of quartz or alumina.

- Quartz tubes are common and cost-effective but are highly susceptible to thermal shock. Heating or cooling them too quickly creates a large temperature difference between the inner and outer surfaces, causing stress that can easily crack the tube.

- Alumina tubes are more durable and can withstand higher temperatures and faster thermal changes. However, even they are not immune to damage from excessively aggressive heating cycles.

Understanding the Trade-offs: Speed vs. Safety

Choosing a heating rate is a deliberate decision with direct consequences for your experiment and your equipment.

The Risk of Faster Rates: Thermal Shock

The primary reason to limit the heating rate is to prevent thermal shock. When you set a rate above 10°C/min, you risk cracking the furnace tube. A broken tube can ruin an experiment, damage the heating elements, and result in costly repairs and downtime.

The Benefit of Slower Rates: Uniformity and Longevity

A slower rate, such as 5°C/min, allows heat to distribute more evenly throughout the furnace chamber and the tube itself. This ensures your sample experiences a uniform temperature and minimizes stress on the components. Adhering to this practice dramatically extends the lifespan of your furnace tube.

The Importance of Controlled Cooling

The risk of thermal shock is just as present during cooldown. The cooling rate should also be controlled, and is typically set to be equal to or slower than the heating rate. A sudden drop in temperature, such as opening the furnace, is a common cause of tube failure.

Making the Right Choice for Your Goal

Use your experimental goal to guide your decision on the proper heating rate.

- If your primary focus is equipment safety and process repeatability: Always use a conservative rate of 5°C/min. This is the best practice for nearly all applications, especially when using quartz tubes.

- If your primary focus is throughput with a robust setup: You may approach 10°C/min, but only if you are using a high-purity alumina tube and have verified your sample can withstand the faster ramp.

- If you are working with sensitive or volatile materials: A slower rate is always better, as it provides a more stable and controlled environment, preventing unwanted side-reactions or thermal decomposition.

Ultimately, managing the heating rate is about controlling the thermal journey of your sample to ensure both repeatable results and the longevity of your equipment.

Summary Table:

| Factor | Impact on Heating Rate |

|---|---|

| Furnace Tube Material | Quartz tubes require slower rates (~5°C/min); Alumina allows slightly faster rates (~10°C/min). |

| Primary Goal | Safety/Repeatability: Use 5°C/min. Throughput (with robust setup): Up to 10°C/min. |

| Key Risk | Exceeding recommended rates risks thermal shock, cracking the tube, and damaging the furnace. |

Achieve precise, reliable thermal processing with a tube furnace built for your specific needs.

At KINTEK, we understand that your experiments demand exact control over heating rates to ensure both sample integrity and equipment longevity. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with advanced high-temperature furnace solutions.

Our product line, including Tube Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements—whether you need robust heating elements for faster ramps or specialized tube materials for sensitive processes.

Let us help you optimize your thermal cycles. Contact our experts today to discuss your application and receive a tailored solution.

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis