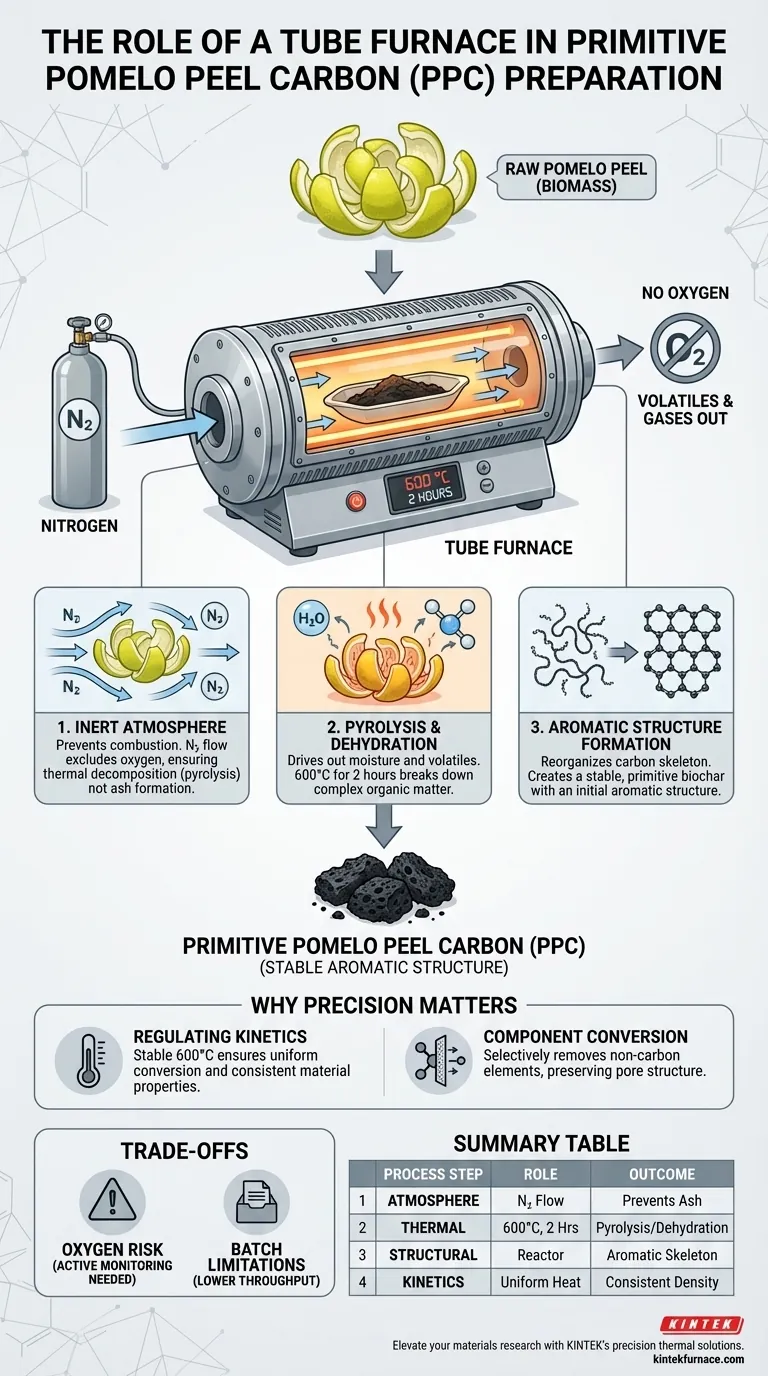

The tube furnace serves as the critical reactor for controlled pyrolysis. In the preparation of primitive pomelo peel carbon (PPC), its primary function is to maintain a strictly oxygen-free environment using nitrogen protection. By subjecting treated pomelo peel to a precise temperature of 600 °C for two hours, the furnace facilitates essential dehydration and carbonization reactions, converting complex organic matter into primitive biochar with a foundational aromatic structure.

The tube furnace is not merely a heat source; it is an isolation chamber that forces the biomass to decompose internally rather than combust. This precise control over atmosphere and temperature is the defining factor that transforms raw fruit peel into a stable, carbonized material.

The Mechanism of Carbonization

To understand the preparation of PPC, you must look beyond simple heating. The tube furnace orchestrates three specific chemical and physical changes.

Establishing the Inert Atmosphere

The most critical role of the tube furnace is oxygen exclusion. By maintaining a continuous flow of nitrogen, the furnace prevents the pomelo peel from burning (oxidizing) into ash. This "nitrogen protection" ensures that the material undergoes thermal decomposition rather than combustion.

Driving Pyrolysis and Dehydration

At the target temperature of 600 °C, the furnace provides the energy required to break down complex organic components. This process, known as pyrolysis, drives out moisture (dehydration) and volatile compounds. The specific duration of two hours allows for thorough reaction completion, ensuring no raw biomass remains.

Formation of Aromatic Structures

The ultimate goal of using the tube furnace is structural transformation. Through carbonization, the chaotic organic structure of the peel is reorganized into a primitive biochar. This results in an "initial aromatic structure," which serves as the stable carbon skeleton for any further activation or modification.

Why Precision Control Matters

The "primitive" in PPC does not imply a crude process; it requires exact conditions to establish a consistent baseline material.

Regulating Reaction Kinetics

The tube furnace allows for the precise regulation of the heating environment. If the temperature deviates from 600 °C, the degree of carbonization will shift, altering the material's properties. Stable heating ensures that the conversion from organic peel to inorganic carbon is uniform throughout the sample.

Component Conversion

The furnace environment facilitates the conversion of specific components without damaging the material's core integrity. It allows for the removal of non-carbon elements while preserving the developing pore structure. This balance is essential for creating a material that can be further processed into activated carbon or other advanced materials.

Understanding the Trade-offs

While the tube furnace is the industry standard for this process, it introduces specific constraints that must be managed.

The Risk of Oxygen Ingress

The system is entirely dependent on the integrity of the gas flow. Even a minor leak or interruption in nitrogen flow at 600 °C will immediately degrade the PPC into useless ash. The "protection" offered by the furnace is active, not passive; it requires constant monitoring.

Batch Limitations

Tube furnaces are typically batch-processing tools, limiting the volume of PPC that can be produced at once. This constraint ensures high quality and uniformity but restricts throughput compared to continuous industrial kilns. For research and high-precision applications, this trade-off is accepted to guarantee the purity of the aromatic structure.

Making the Right Choice for Your Goal

When preparing primitive pomelo peel carbon, your operational focus determines your success.

- If your primary focus is material yield: Ensure the nitrogen flow is robust and continuous to prevent oxidative loss of the carbon skeleton.

- If your primary focus is structural consistency: Adhere strictly to the 600 °C set point and the two-hour duration to guarantee a uniform aromatic structure.

The tube furnace is the bridge between organic waste and functional material, turning raw potential into a stable, engineered carbon framework.

Summary Table:

| Process Step | Role of Tube Furnace | Outcome for PPC |

|---|---|---|

| Atmosphere Control | Nitrogen flow/Oxygen exclusion | Prevents combustion and ash formation |

| Thermal Treatment | Precise 600°C for 2 hours | Facilitates dehydration and complete pyrolysis |

| Structural Change | High-temperature reactor | Converts biomass into stable aromatic carbon skeleton |

| Kinetics Control | Uniform heating environment | Ensures consistent material density and pore structure |

Elevate your carbon materials research with KINTEK’s precision thermal solutions. Whether you are producing PPC or advanced activated carbon, our high-performance Tube, Vacuum, and CVD systems offer the atmosphere integrity and temperature accuracy your lab demands. Backed by expert R&D and manufacturing, KINTEK provides customizable lab furnaces tailored to your unique research needs. Contact us today to optimize your pyrolysis process!

Visual Guide

References

- Jing Gong, Baowei Hu. Honeycomb-structured biochar from waste pomelo peel for synergistic adsorptive and photocatalytic removal of Cr(VI). DOI: 10.1007/s44246-024-00174-5

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- Can you provide an example of a material prepared using a tube furnace? Discover YBa₂Cu₃O₇ Synthesis

- Why is a high-temperature tube furnace required for the preparation of non-enzymatic glucose sensor electrodes?

- How does a high-temperature tube furnace contribute to the atmosphere-controlled sintering of Mn-Zn ferrites?

- What are the main applications of a vertical tube furnace? Leverage Gravity for Superior Thermal Processing

- What environmental applications do rotary tube furnaces have? Transform Waste into Value with Advanced Thermal Processing

- What is the role of horizontal furnaces in battery manufacturing? Achieve Precision Thermal Processing for Superior Battery Performance

- What role does an industrial vertical tube furnace play in Si-O equilibria? Master High Silicon Steel Experiments

- What types of atmospheric conditions can tubular furnaces operate under? Master Precise Control for Material Synthesis