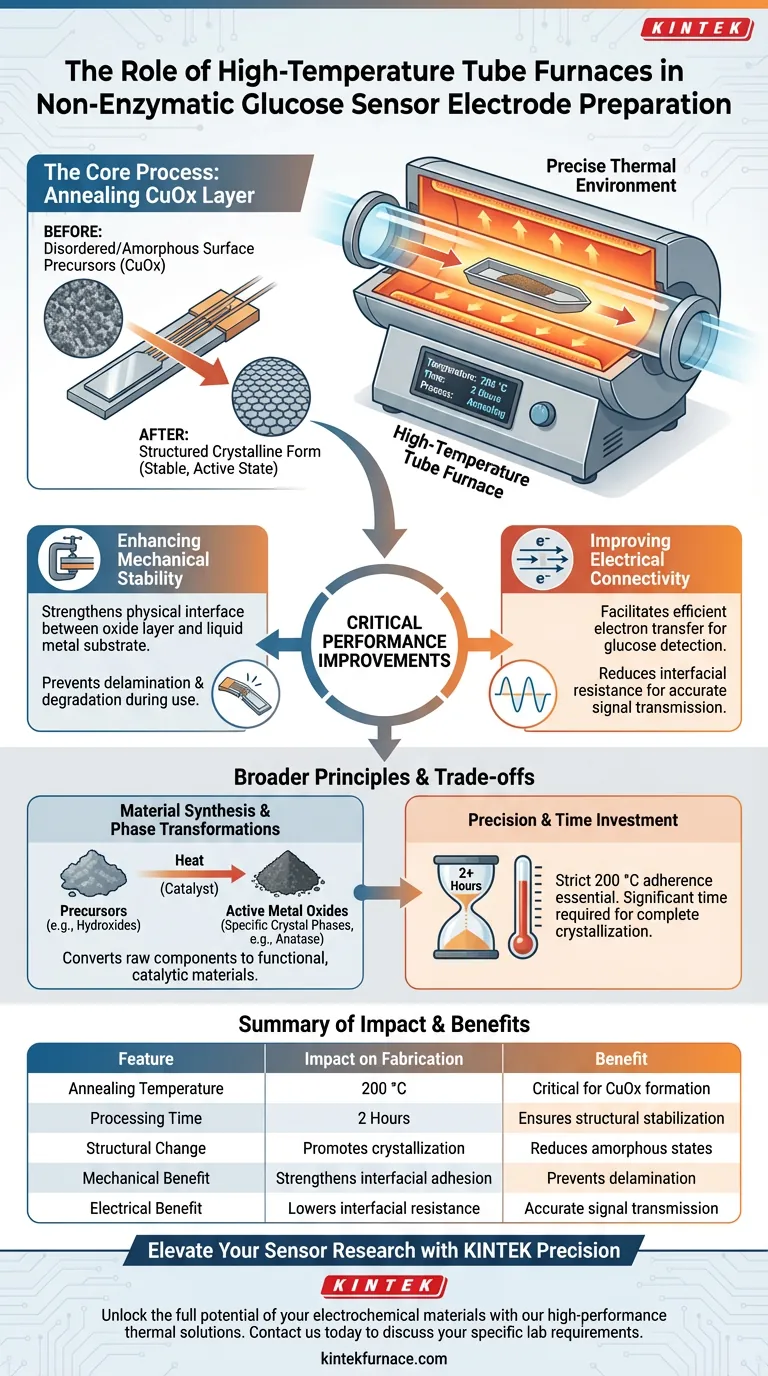

A high-temperature tube furnace is required because it provides the precise thermal environment necessary to anneal the sensor materials, specifically transforming surface precursors into a stable, active state. In the preparation of non-enzymatic glucose sensors, this equipment subjects the copper oxide (CuOx) layer to a controlled temperature of 200 °C for 2 hours, a critical step that dictates the final quality of the electrode.

The tube furnace is not merely a drying tool; it is a mechanism for structural stabilization. By promoting crystallization, the thermal treatment transforms a fragile surface layer into a mechanically robust and electrically conductive interface essential for accurate glucose detection.

The Role of Thermal Treatment in Fabrication

Promoting Crystallization

The primary function of the tube furnace is to facilitate annealing. This process drives the transition of the copper oxide layer from a potentially disordered or amorphous state into a structured crystalline form.

Optimizing the Oxide Layer

Specific thermal parameters are required to achieve the correct material phase. As noted in the primary fabrication method, maintaining the environment at 200 °C for exactly 2 hours allows the CuOx layer to form correctly on the liquid metal surface via displacement reactions.

Critical Performance Improvements

Enhancing Mechanical Stability

A sensor must withstand physical stress during operation. The annealing process strengthens the physical interface between the active oxide layer and the liquid metal substrate.

Without this thermal treatment, the active materials would likely suffer from poor adhesion. The furnace ensures the layer is mechanically stable, preventing delamination or degradation during use.

Improving Electrical Connectivity

Non-enzymatic sensors rely on efficient electron transfer to detect glucose levels. The heat treatment significantly enhances the electrical connectivity between the active materials and the underlying substrate.

By reducing interfacial resistance, the furnace ensures that the chemical signals generated by glucose oxidation are accurately transmitted through the electrode.

Broader Principles of Material Synthesis

Converting Precursors to Active Phases

While the specific application uses a tube furnace, the underlying principle mirrors that of high-temperature muffle furnaces used in broader material science.

Thermal treatment is generally required to convert precursors—such as metal hydroxides or salts—into their final metal oxide forms.

Inducing Phase Transformations

Heat is the catalyst for necessary phase changes. For example, thermal treatment can convert amorphous materials (like titanium dioxide nanotubes) into specific active phases (such as anatase).

This transformation is crucial because specific crystal phases often possess superior electrochemical catalytic properties, directly improving the sensor's sensitivity.

Understanding the Trade-offs

Precision is Non-Negotiable

The effectiveness of the tube furnace relies entirely on strict adherence to temperature protocols. Deviating from the 200 °C benchmark can lead to incomplete crystallization or, conversely, thermal damage to the substrate.

The Cost of Time

The process requires a significant time investment—specifically the 2-hour dwelling time plus ramp-up and cool-down periods. This is a bottleneck in rapid manufacturing but is a necessary trade-off for ensuring material integrity.

Making the Right Choice for Your Goal

To maximize the performance of your glucose sensor electrodes, focus on the specific outcome you need from the thermal treatment:

- If your primary focus is Mechanical Durability: Strictly adhere to the 2-hour annealing duration to maximize the bonding strength between the oxide layer and the liquid metal substrate.

- If your primary focus is Sensor Sensitivity: Prioritize precise temperature control at 200 °C to ensure complete crystallization, which optimizes electrical conductivity and catalytic performance.

Ultimately, the high-temperature tube furnace acts as the bridge between raw chemical components and a functional, high-performance diagnostic tool.

Summary Table:

| Feature | Impact on Glucose Sensor Fabrication |

|---|---|

| Annealing Temperature | 200 °C (Critical for CuOx formation) |

| Processing Time | 2 Hours (Ensures structural stabilization) |

| Structural Change | Promotes crystallization and reduces amorphous states |

| Mechanical Benefit | Prevents delamination by strengthening interfacial adhesion |

| Electrical Benefit | Lowers interfacial resistance for accurate signal transmission |

Elevate Your Sensor Research with KINTEK Precision

Unlock the full potential of your electrochemical materials with KINTEK’s high-performance thermal solutions. Backed by expert R&D and world-class manufacturing, we provide high-precision Tube, Muffle, Vacuum, and CVD systems designed to meet the rigorous demands of glucose sensor development.

Whether you require exact temperature uniformity for crystallization or customizable furnace configurations for unique material synthesis, KINTEK delivers the reliability you need. Contact us today to discuss your specific lab requirements and discover how our advanced heating technology can optimize your electrode fabrication process.

Visual Guide

References

- Yiyao Luo, Xiang Qi. Printing surface cuprous oxides featured liquid metal for non-enzymatic electrochemical glucose sensor. DOI: 10.20517/ss.2023.40

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- Why is high-temperature annealing in a tube furnace necessary for LaAlO3? Optimize TiO2 Thin Film Adhesion

- How does atmosphere control in a laboratory tube furnace affect Boron Carbide powders? Optimize Your Surface Chemistry

- What are the main advantages of vacuum tube furnaces in the market? Achieve Purity and Precision in Material Processing

- What common processes are enabled by tube furnaces? Unlock Precise Thermal Processing for Your Lab

- How does the hydrogen reduction process in a laboratory tube furnace facilitate the exsolution of nickel species?

- How are horizontal furnaces used in materials science? Unlock Precision in Heat Treatment

- What are the space-saving benefits of a tube furnace? Maximize Lab Efficiency with Compact Design

- Why is an industrial-grade high-temperature tube furnace used for TiO2NW? Optimize Nanowire Annealing