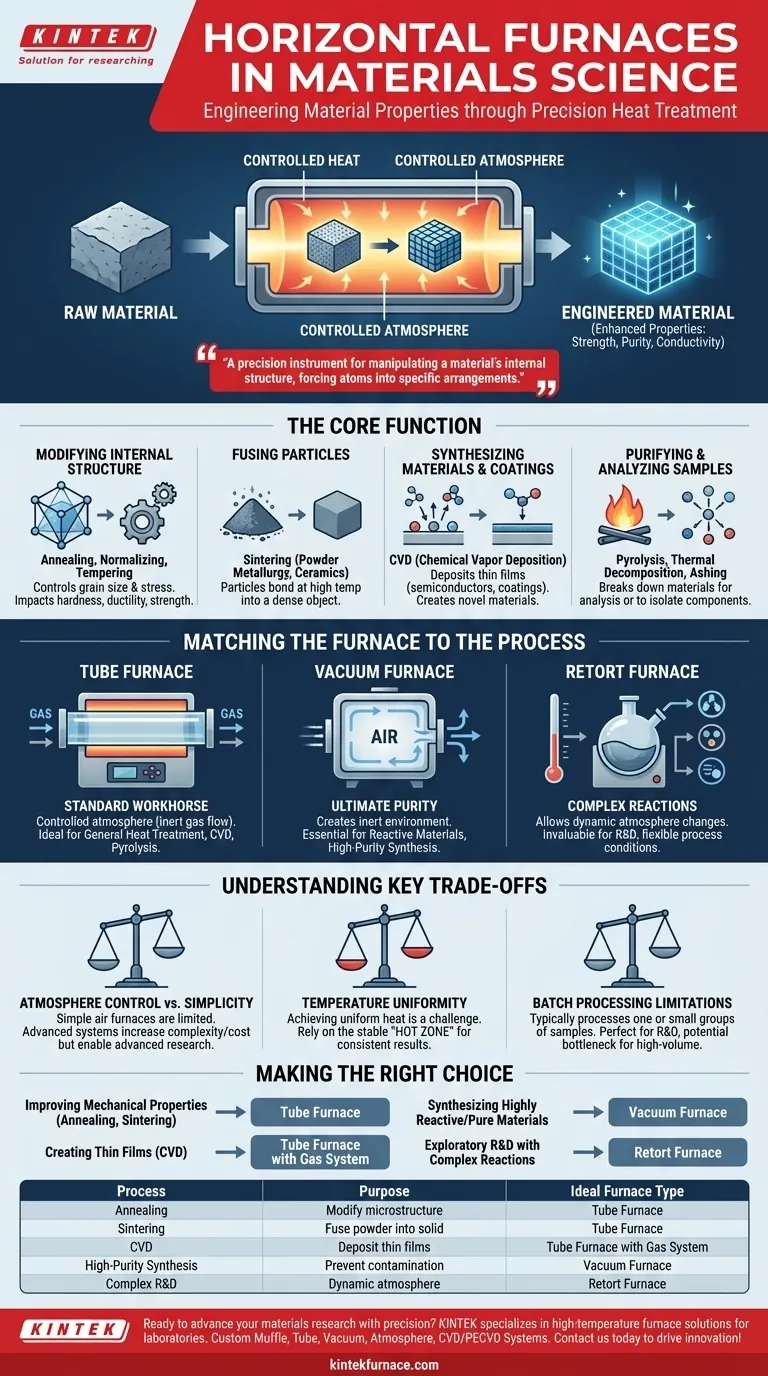

In materials science, horizontal furnaces are essential tools used to precisely control the heat treatment of materials. They enable fundamental processes like annealing, sintering, and chemical vapor deposition (CVD), which are used to synthesize new materials or refine the properties of existing ones, such as their strength, purity, or electrical conductivity.

A horizontal furnace is more than an oven; it is a precision instrument for manipulating a material's internal structure. The core purpose is to use controlled temperature, and often a controlled atmosphere, to force atoms into a specific arrangement, thereby engineering the exact material properties required for an application.

The Core Function: Engineering Material Properties

The ultimate goal of using a horizontal furnace is to intentionally alter a material's physical or chemical characteristics. This is achieved through several distinct thermal processes.

Modifying Internal Structure

Annealing, normalizing, and tempering are heat treatment processes that modify a material's microstructure. By carefully heating and cooling a material, you can control its grain size and internal stresses.

This directly impacts mechanical properties like hardness, ductility, and strength.

Fusing Particles Together

Sintering is a process used heavily in powder metallurgy and ceramics manufacturing. It involves heating compacted powder to a temperature below its melting point.

At this temperature, the individual particles bond and fuse, creating a solid, dense object.

Synthesizing Materials and Coatings

Chemical Vapor Deposition (CVD) is a technique where a furnace is used to deposit a thin film of material onto a substrate. Gaseous reactants decompose in the hot zone of the furnace, creating a solid layer critical for semiconductors and protective coatings.

Furnaces are also used for general material synthesis, creating novel materials like nanomaterials, composites, and advanced ceramics from precursor chemicals.

Purifying and Analyzing Samples

Processes like pyrolysis and thermal decomposition use heat to break down materials, often in an oxygen-free environment. This is used to analyze a material's composition or to produce simpler chemical components.

Similarly, ashing involves burning off organic matter to isolate the inorganic, non-combustible components of a sample for analysis.

Matching the Furnace to the Process

While "horizontal furnace" is a broad category, specialized types are used for specific scientific goals. The primary difference is how they control the atmosphere around the sample.

The Standard Workhorse: The Tube Furnace

The most common type is the tube furnace, which features a ceramic or quartz tube running through the heated chamber. This design is ideal for creating a controlled atmosphere.

By flowing specific gases (like argon or nitrogen) through the tube, you can prevent unwanted chemical reactions, such as oxidation. This makes it perfect for general heat treatment, CVD, and pyrolysis.

For Ultimate Purity: The Vacuum Furnace

A vacuum tube furnace is a specialized variant used when even trace amounts of atmospheric gas would compromise the material. By pumping all the air out, it creates an inert environment.

This is non-negotiable for treating highly reactive materials or synthesizing materials where purity is paramount, such as high-temperature superconductors and certain nanomaterials.

For Complex Reactions: The Retort Furnace

A retort furnace offers unique flexibility by allowing the atmosphere to be altered during a single process cycle.

This capability is invaluable for complex research and development, enabling scientists to study chemical reactions under dynamically changing conditions without disturbing the sample.

Understanding the Key Trade-offs

Choosing and using a horizontal furnace involves balancing competing factors. Understanding these limitations is critical for achieving reliable and repeatable results.

Atmosphere Control vs. Simplicity

A simple air-atmosphere furnace is easy to operate but severely limits the types of materials you can process. Adding gas or vacuum systems for atmosphere control increases complexity and cost but is essential for most advanced materials research.

Temperature Uniformity

Achieving a perfectly uniform temperature across the entire sample is a significant challenge. Most furnaces have a specified "hot zone," the central region with the most stable and uniform temperature. Placing your sample outside this zone will lead to inconsistent results.

Batch Processing Limitations

Most laboratory-scale horizontal furnaces are designed for batch processing, meaning one sample or a small group of samples is processed at a time. While perfect for R&D, this can be a bottleneck for any process requiring high-volume manufacturing.

Making the Right Choice for Your Goal

Your specific research or production goal dictates the type of thermal process and furnace you require.

- If your primary focus is improving mechanical properties: You will rely on annealing and sintering processes, where precise temperature control is more critical than atmosphere.

- If your primary focus is creating thin films or coatings: You need a tube furnace equipped with a gas delivery system to perform Chemical Vapor Deposition (CVD).

- If your primary focus is synthesizing highly reactive or pure materials: A vacuum furnace is essential to prevent oxidation and contamination during high-temperature treatment.

- If your primary focus is exploratory R&D with complex reactions: A versatile retort furnace or a multi-zone tube furnace will provide the most process flexibility.

Ultimately, mastering thermal processing is fundamental to pushing the boundaries of what materials can do.

Summary Table:

| Process | Purpose | Ideal Furnace Type |

|---|---|---|

| Annealing | Modify microstructure for improved mechanical properties | Tube Furnace |

| Sintering | Fuse powder particles into solid objects | Tube Furnace |

| Chemical Vapor Deposition (CVD) | Deposit thin films or coatings | Tube Furnace with Gas System |

| High-Purity Synthesis | Prevent contamination in reactive materials | Vacuum Furnace |

| Complex R&D | Alter atmosphere dynamically during processes | Retort Furnace |

Ready to advance your materials research with precision? At KINTEK, we specialize in high-temperature furnace solutions tailored for laboratories. Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental needs, whether you're working on annealing, sintering, CVD, or high-purity synthesis. Contact us today to discuss how our furnaces can enhance your material properties and drive innovation in your lab!

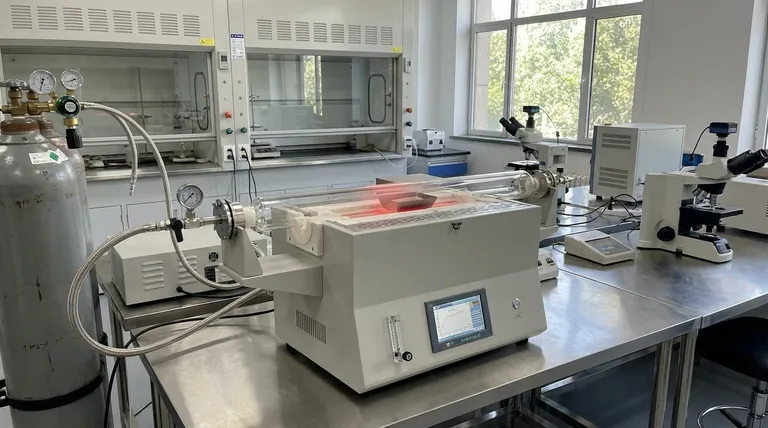

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency