At its core, a tube furnace is a high-temperature oven used to perform a wide range of thermal processes on small samples. Common applications include annealing to improve material ductility, calcination for thermal decomposition, sintering to fuse powders into solids, and chemical vapor deposition (CVD) to create thin films, all of which depend on precise temperature and atmospheric control.

The defining advantage of a tube furnace is not just its ability to generate high heat, but its capacity to do so within a tightly sealed, controlled atmosphere. This makes it indispensable for processes where exposure to ambient air would compromise the material or prevent the desired chemical reaction.

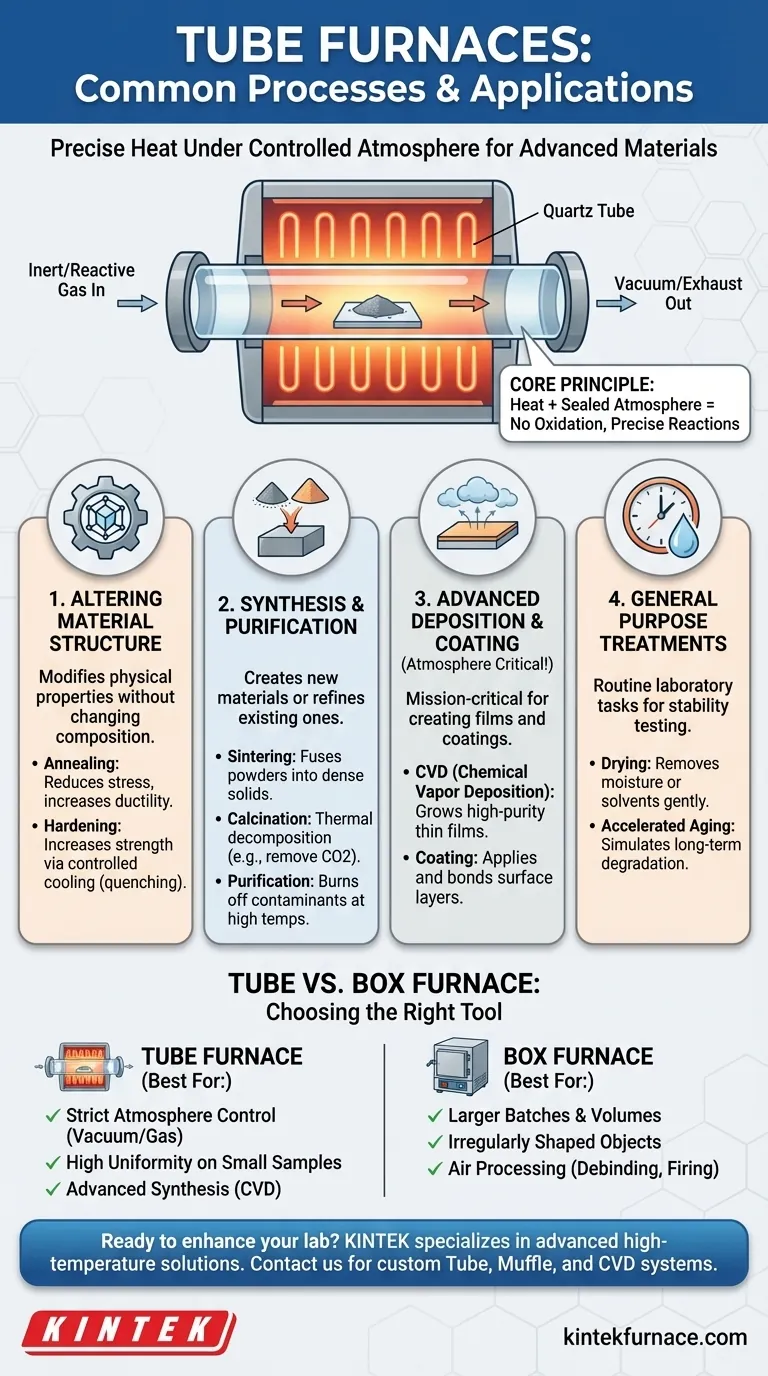

The Core Principle: Heat Under Atmospheric Control

A tube furnace's unique value comes from the synergy between its heating elements and the containment tube, which is typically made of quartz, alumina, or mullite. This design enables two critical functions.

Why a Controlled Atmosphere is Essential

The sealed tube allows you to introduce specific gases or create a vacuum. This is crucial for preventing unwanted chemical reactions, like oxidation, that would occur in open air.

By flowing an inert gas (like argon or nitrogen), you can protect sensitive materials during processes like annealing. Conversely, introducing reactive gases is the foundation for advanced synthesis techniques like Chemical Vapor Deposition (CVD).

Achieving Uniform High Temperatures

Tube furnaces use different heating elements to reach specific temperature ranges. This allows you to match the furnace to the process requirements.

- Kanthal (A-1) elements are common for temperatures up to 1200°C.

- Silicon Carbide (SiC) elements are used for mid-range applications up to 1500°C.

- Molybdenum Disilicide (MoSi2) elements achieve the highest temperatures, reaching 1800°C or more.

The cylindrical heating chamber naturally promotes a uniform "hot zone" along the length of the tube, ensuring the entire sample receives consistent thermal treatment.

Common Thermal Processes Explained

The combination of heat and atmospheric control enables a diverse set of scientific and industrial processes.

Altering Material Structure

These processes modify the physical properties of a material without changing its chemical composition.

Annealing involves heating a material and slowly cooling it to remove internal stresses, increase ductility, and make it less brittle.

Hardening uses controlled heating and rapid cooling (quenching) to increase the hardness and strength of metals.

Material Synthesis and Purification

These processes create new materials or refine existing ones.

Sintering heats compacted powders to just below their melting point, causing the particles to fuse together into a solid, dense object. This is fundamental to ceramics and powder metallurgy.

Calcination heats a material to drive off volatile substances, such as water or carbon dioxide, inducing thermal decomposition. It is a key step in cement production and preparing catalysts.

Purification leverages high temperatures to burn off organic contaminants or separate compounds based on their different vaporization points.

Advanced Deposition and Coating

This is where the atmospheric control of a tube furnace becomes mission-critical.

Chemical Vapor Deposition (CVD) is a process where volatile precursor gases are introduced into the furnace. The high heat causes them to react and decompose, depositing a high-purity, solid thin film onto a substrate.

Coating can also refer to simpler processes where a substance is applied to a sample and then heat-treated to bond it to the surface.

General Purpose Treatments

Tube furnaces are also workhorses for more routine laboratory tasks.

Drying involves gently heating a sample to remove moisture or other solvents.

Accelerated Aging uses elevated temperatures to simulate the effects of time on a material, allowing for rapid testing of its long-term stability and degradation.

Understanding the Trade-offs: Tube Furnace vs. Box Furnace

While many processes can be done in either furnace type, their designs make them suitable for different priorities. The choice often comes down to atmosphere versus volume.

When to Choose a Tube Furnace

A tube furnace is the superior choice when the atmosphere must be strictly controlled. If your process requires a vacuum, an inert gas environment, or the introduction of reactive gases (like in CVD), the sealed tube is non-negotiable.

Its smaller diameter is ideal for achieving high thermal uniformity on small, consistently shaped samples.

When a Box Furnace May Suffice

A box furnace is better suited for processing larger batches, irregularly shaped objects, or when the process can be performed in ambient air.

Processes like debinding, basic ceramics firing, or heat-treating non-reactive metals are often done in box furnaces due to their larger chamber volume and easier loading/unloading.

Making the Right Choice for Your Application

Selecting the right equipment depends entirely on your end goal.

- If your primary focus is advanced synthesis or atmospheric control (CVD, sensitive metal annealing, reactive gas processing): A tube furnace is the only suitable choice.

- If your primary focus is modifying material properties in a controlled environment (sintering, calcination, purification): A tube furnace provides the necessary precision and protection from oxidation.

- If your primary focus is processing large items or high-throughput batches in air: A box furnace is likely the more practical and cost-effective solution.

Ultimately, understanding your material's sensitivity to its environment is the key to selecting the proper thermal processing tool.

Summary Table:

| Process Type | Key Processes | Key Benefits |

|---|---|---|

| Material Structure Alteration | Annealing, Hardening | Increases ductility, removes stresses, enhances hardness |

| Synthesis and Purification | Sintering, Calcination, Purification | Fuses powders, decomposes materials, removes contaminants |

| Deposition and Coating | Chemical Vapor Deposition (CVD), Coating | Creates thin films, bonds coatings to substrates |

| General Treatments | Drying, Accelerated Aging | Removes moisture, simulates long-term aging effects |

Ready to enhance your lab's capabilities with precise thermal processing? KINTEK specializes in advanced high-temperature furnace solutions, including Tube Furnaces, Muffle Furnaces, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With our strong R&D and in-house manufacturing, we offer deep customization to meet your unique experimental needs—ensuring optimal performance for processes like annealing, sintering, and CVD. Contact us today to discuss how we can support your research and development goals!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide