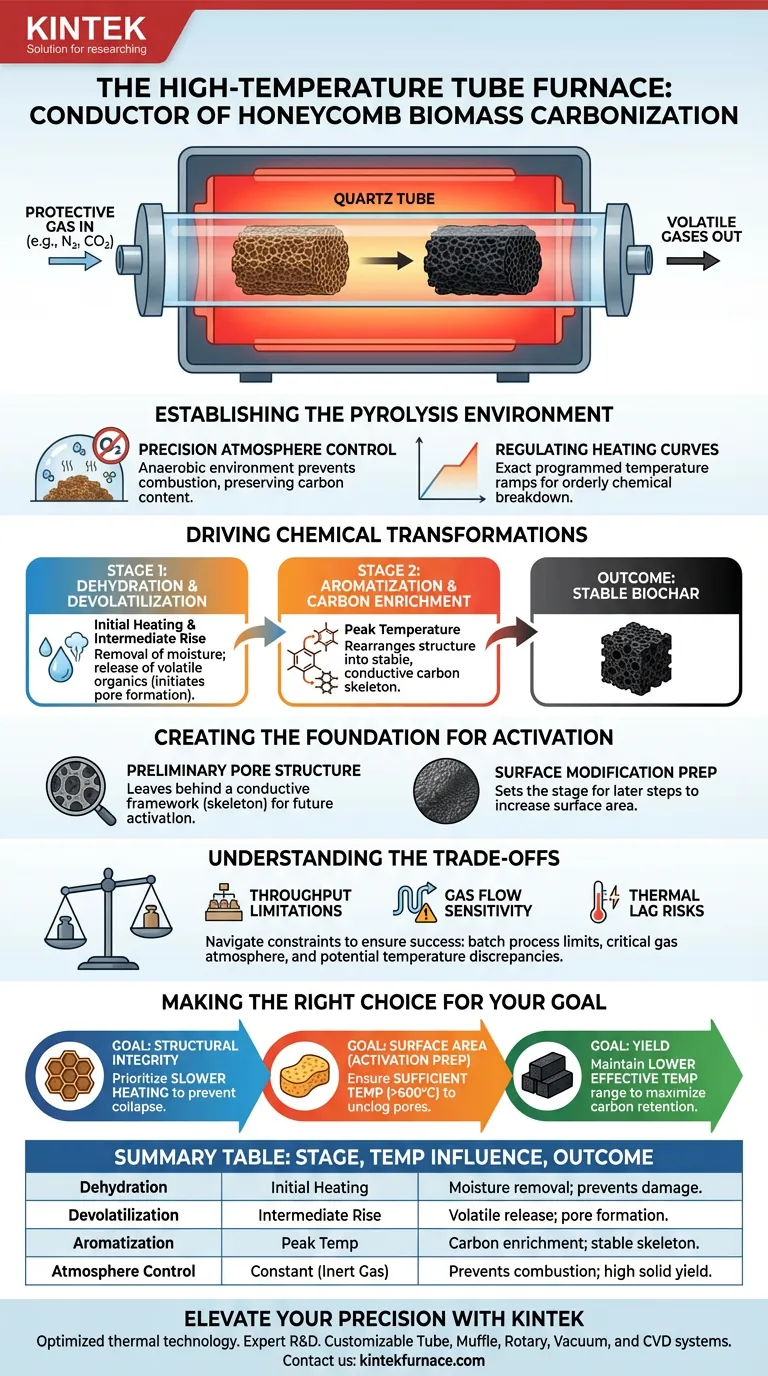

The primary role of a high-temperature tube furnace in this process is to provide a strictly controlled pyrolysis environment. It isolates the honeycomb biomass within a sealed chamber, subjecting it to precise heating curves under a constant flow of protective gas to convert raw organic material into a stable, porous carbon structure.

Core Takeaway The tube furnace does not merely heat the material; it drives the essential chemical sequence of dehydration, devolatilization, and aromatization. By maintaining an oxygen-free atmosphere, it prevents combustion and ensures the biomass transforms into a solid biochar "skeleton" with the initial pore structure required for future activation.

Establishing the Pyrolysis Environment

To transform honeycomb biomass (such as Slumgum) into effective biochar, the processing environment must be rigorously managed. The tube furnace acts as the central control unit for these variables.

Precision Atmosphere Control

The most critical function of the furnace is creating an anaerobic (oxygen-free) environment.

By maintaining a constant flow of protective gases, such as nitrogen or carbon dioxide, the furnace prevents the biomass from burning into ash. This allows the material to undergo thermal decomposition (pyrolysis) rather than combustion, preserving the carbon content.

Regulating Heating Curves

Carbonization is not instantaneous; it requires specific temperature ramps. The tube furnace allows operators to program exact heating curves.

This control ensures the biomass is heated at a rate that facilitates orderly chemical breakdown. Rapid fluctuations or uncontrolled heating can damage the developing carbon structure, making the precision of the tube furnace essential.

Driving Chemical Transformations

Inside the furnace, the high-temperature environment drives three specific reaction stages responsible for converting raw biomass into biochar.

Dehydration and Devolatilization

As the furnace heats up, it first drives off moisture (dehydration). As temperatures rise further, the furnace facilitates devolatilization.

During this phase, volatile components within the honeycomb biomass are released as gases. This step is critical for breaking down the initial organic composition without destroying the physical matrix of the material.

Aromatization and Carbon Enrichment

Once volatiles are removed, the furnace maintains high temperatures to drive aromatization.

This process rearranges the chemical structure, converting the remaining organic components into a stable, carbon-enriched solid. This transformation creates the durability and chemical stability characteristic of high-quality biochar.

Creating the Foundation for Activation

The ultimate goal of using a tube furnace for carbonization is to prepare the material for subsequent processing.

Developing the Initial Pore Structure

The furnace converts the raw biomass into a solid biochar with a preliminary pore structure.

By carefully removing organic matter, the furnace leaves behind a conductive framework. This "skeleton" is the necessary foundation for any future physical or chemical activation.

Preparing for Surface Modification

While the carbonization process establishes the structure, it also prepares the surface chemistry.

The thermal treatment preserves the integrity of the biomass while effectively "setting the stage" for later steps that will increase surface area. Without this controlled carbonization, subsequent activation would lack a stable substrate to act upon.

Understanding the Trade-offs

While high-temperature tube furnaces are the standard for precision carbonization, there are constraints you must navigate to ensure success.

1. Throughput Limitations Tube furnaces are typically batch-process or small-scale continuous devices. They offer exceptional control for research and high-quality production but may become a bottleneck if you are attempting to process massive volumes of biomass rapidly.

2. Sensitivity to Gas Flow Interruption The quality of the biochar is entirely dependent on the protective gas atmosphere. Any interruption or fluctuation in the nitrogen or CO2 flow can introduce oxygen, leading to partial combustion, surface oxidation, and a significant loss of yield.

3. Thermal Lag Risks Although precise, there can be a discrepancy between the furnace setpoint and the actual sample temperature inside the tube. You must account for heat transfer rates into the honeycomb structure to ensure the core of the biomass reaches the target carbonization temperature.

Making the Right Choice for Your Goal

The way you utilize the tube furnace should shift based on your specific objectives for the biochar.

- If your primary focus is Structural Integrity: Prioritize slower heating rates within the furnace to prevent rapid outgassing from collapsing the delicate honeycomb pores.

- If your primary focus is Surface Area (Activation Prep): Ensure the furnace reaches sufficient temperatures (typically above 600°C) to fully complete devolatilization, ensuring the pores are unclogged and ready for activation agents.

- If your primary focus is Yield: Maintain the lower end of the effective pyrolysis temperature range to maximize solid carbon retention while still achieving necessary aromatization.

Success in carbonization relies not just on high heat, but on the precise orchestration of temperature and atmosphere that only a tube furnace can provide.

Summary Table:

| Stage | Temperature Influence | Chemical/Physical Outcome |

|---|---|---|

| Dehydration | Initial Heating | Removal of moisture; prevents structural steam damage. |

| Devolatilization | Intermediate Rise | Release of volatile organic compounds; initiates pore formation. |

| Aromatization | Peak Temperature | Carbon enrichment; creates stable, conductive carbon skeleton. |

| Atmosphere Control | Constant (Inert Gas) | Prevents combustion; ensures high yield of solid biochar. |

Elevate Your Carbonization Precision with KINTEK

Are you looking to optimize your biomass transformation or research? KINTEK provides the cutting-edge thermal technology required for success. Backed by expert R&D and manufacturing, we offer a comprehensive range of Tube, Muffle, Rotary, Vacuum, and CVD systems, all of which are fully customizable to meet your unique laboratory or production needs.

Our high-temperature furnaces ensure the rigorous atmosphere control and precise heating curves essential for developing high-quality biochar and advanced materials. Contact us today to discuss your project requirements and discover how our specialized heating solutions can bring unparalleled consistency to your results.

Visual Guide

References

- Kinga Morlo, Ryszard Dobrowolski. Optimization of Pt(II) and Pt(IV) Adsorption from a Water Solution on Biochar Originating from Honeycomb Biomass. DOI: 10.3390/molecules29020547

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What design aspects of a split tube furnace influence its performance? Optimize for Temperature Uniformity and Efficiency

- Why are sealed quartz tubes required for Au-Seeded TiO2 nanowires? Ensure Vapor-Phase Stability and VLS Growth

- What are the main components of a tube furnace? Essential Parts for Precise High-Temperature Processing

- What are the applications of fluidized bed vertical tube furnaces? Achieve Uniform Heating for Powdered Materials

- What are the main advantages of a vertical tube furnace? Superior Purity, Uniformity, and Space Savings

- How does a high-temperature tube furnace contribute to the atmosphere-controlled sintering of Mn-Zn ferrites?

- How does the temperature control program of a tube furnace affect NiSSe nanocrystal formation? Optimize Your Synthesis

- What are the key heat treatment processes performed in horizontal furnaces? Master Annealing, Hardening, and More