In essence, an atmosphere tube furnace is a specialized piece of high-temperature equipment designed to heat materials within a sealed chamber. Its defining feature is the precise control it offers over the gaseous environment, or "atmosphere," surrounding the sample, allowing for processes that would be impossible in open air. This capability is critical in materials science, chemical engineering, and advanced manufacturing.

The true value of an atmosphere tube furnace isn't merely its ability to achieve high temperatures, but its power to create and maintain a pure, customized chemical environment. This control prevents unwanted reactions and enables the synthesis of highly advanced materials.

How an Atmosphere Tube Furnace Works

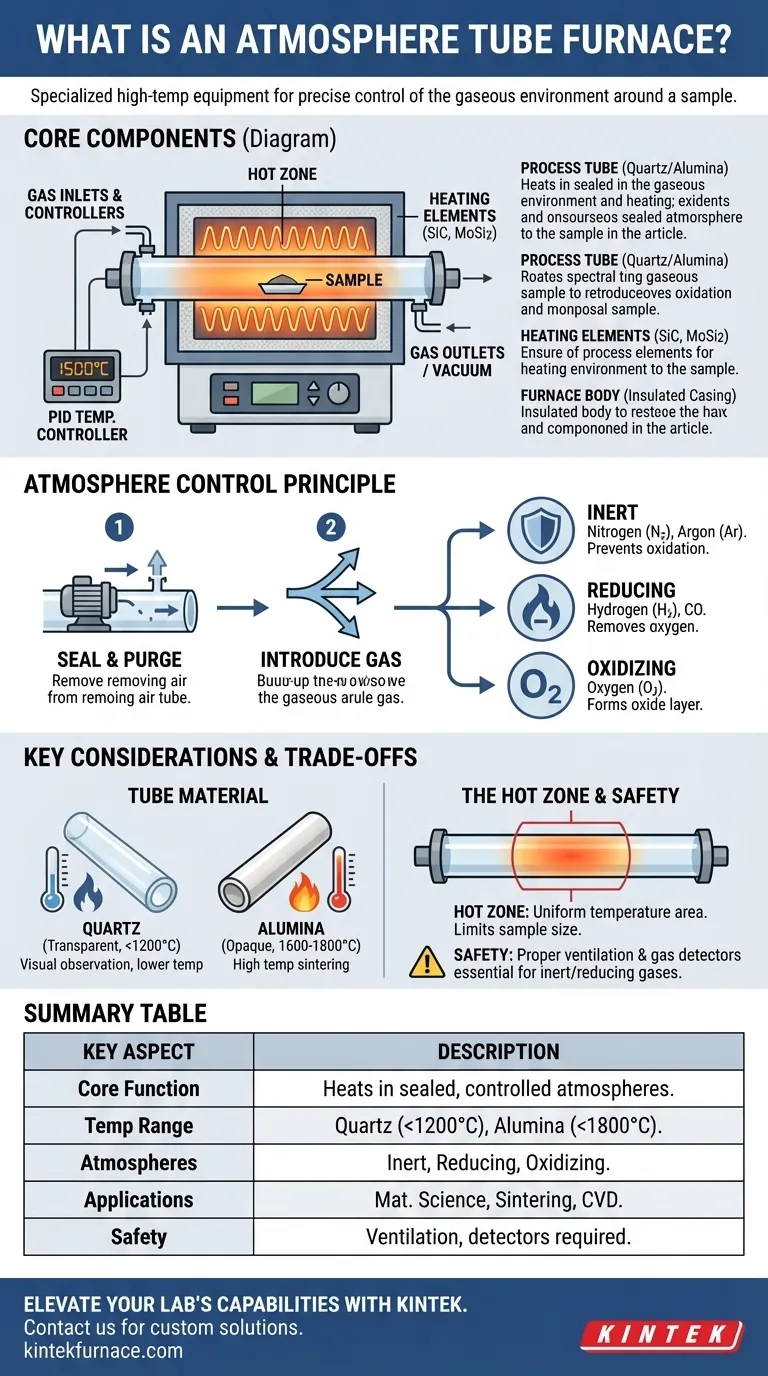

An atmosphere tube furnace integrates several key systems to create a highly controlled processing environment. Understanding these components clarifies its function and versatility.

The Core Components

The furnace is a system of interconnected parts, each with a specific role.

-

The Furnace Body: This is the insulated outer casing, typically made of steel, which contains the heating elements and provides structural support. Its primary job is to contain the heat and ensure energy efficiency.

-

Heating Elements: These are responsible for generating the heat. Most modern lab furnaces use long-lasting electric resistance elements, such as silicon carbide (SiC) or molybdenum disilicide (MoSi2), positioned around the process tube.

-

The Process Tube: This is the heart of the furnace. It's a hollow tube, made of a material appropriate for the target temperature and chemical environment, that passes through the heating chamber. Your samples are placed inside this tube.

-

The Control Systems: This includes a temperature controller (typically a PID controller connected to a thermocouple) for precise heat regulation and an atmosphere controller (gas inlets, valves, and flow meters) to manage the type, pressure, and flow rate of gases inside the tube.

The Principle of Atmosphere Control

The process begins by sealing the sample inside the process tube. The system then purges the ambient air using a vacuum pump or by flushing it with a specific gas.

Once the air is removed, a desired atmosphere is introduced and maintained. This can be:

- Inert: Using gases like Nitrogen (N2) or Argon (Ar) to create a neutral environment that prevents oxidation and contamination.

- Reducing: Using gases like Hydrogen (H2) or Carbon Monoxide (CO) to actively remove oxygen from a material (e.g., reducing a metal oxide).

- Oxidizing: Using gases like Oxygen (O2) to intentionally form an oxide layer on a material's surface.

Achieving Precise Temperature

A thermocouple sensor placed near the process tube constantly measures the temperature. This data is fed to a PID (Proportional-Integral-Derivative) controller, which intelligently adjusts the power sent to the heating elements to maintain a stable, uniform temperature with minimal fluctuation.

Understanding the Trade-offs and Key Considerations

While powerful, an atmosphere tube furnace has limitations and requires careful consideration of its components and operating procedures.

Process Tube Material Dictates Use

The choice of tube material is the single most important factor limiting the furnace's operation.

- Quartz: Transparent and relatively inexpensive, but typically limited to temperatures below 1100-1200°C. It is excellent for processes where visual observation is needed.

- Alumina (Ceramic): Opaque but capable of handling very high temperatures (1600-1800°C). It is the standard for high-temperature sintering and annealing.

- Heat-Resistant Steel/Alloys: Useful for specific applications where thermal shock resistance is needed, but they have lower temperature limits than ceramics and can react with certain process gases.

The "Hot Zone" and Uniformity

Heating elements create a central "hot zone" where the temperature is most uniform. The length of this zone determines the maximum size of a sample that can be processed evenly. For larger or longer samples, a three-zone furnace with independent controllers for each zone may be required to ensure temperature uniformity.

Safety with Process Gases

Working with controlled atmospheres introduces inherent risks. Inert gases like nitrogen and argon are asphyxiants, while reducing gases like hydrogen are highly flammable. A safe setup requires proper ventilation, gas leak detectors, and established safety protocols for handling pressurized gas cylinders.

Making the Right Choice for Your Process

Selecting the correct furnace configuration depends entirely on your specific scientific or industrial goal.

- If your primary focus is high-purity metal annealing: Prioritize a furnace with a high-quality vacuum system to remove all air before backfilling with an inert gas like Argon.

- If your primary focus is high-temperature ceramic sintering: A furnace with a high-purity alumina tube capable of reaching temperatures above 1500°C is essential.

- If your primary focus is experimental synthesis like Chemical Vapor Deposition (CVD): Focus on a system with precise mass flow controllers for multiple gas lines and integrated safety interlocks.

Ultimately, choosing the right atmosphere tube furnace requires a clear understanding of your material, your target temperature, and the specific chemical environment your process demands.

Summary Table:

| Key Aspect | Description |

|---|---|

| Core Function | Heats materials in a sealed chamber with controlled gas atmospheres for specialized processes. |

| Temperature Range | Varies by tube material: Quartz (up to 1200°C), Alumina (up to 1800°C), Steel alloys (lower limits). |

| Atmosphere Types | Inert (e.g., N2, Ar), Reducing (e.g., H2, CO), Oxidizing (e.g., O2). |

| Applications | Materials science, chemical engineering, metal annealing, ceramic sintering, CVD synthesis. |

| Safety Considerations | Risks include asphyxiation from inert gases and flammability from reducing gases; requires ventilation and detectors. |

Elevate Your Laboratory's Capabilities with KINTEK

At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line, including Tube Furnaces, Muffle Furnaces, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is designed for precision and reliability. With strong deep customization capabilities, we can precisely meet your unique experimental requirements, whether for metal annealing, ceramic sintering, or CVD synthesis.

Contact us today to discuss how our atmosphere tube furnaces can enhance your processes and drive innovation in your lab. Get in touch now!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What is the main purpose of heat treatment? Transform Metal Properties for Superior Performance

- How does nitrogen atmosphere heat treatment improve surface strengthening? Enhance Durability and Performance

- What are the benefits of inert atmosphere heat treating? Prevent Oxidation and Preserve Material Integrity

- How does a chemically inert atmosphere function in a furnace? Prevent Oxidation and Ensure Material Purity

- What are the environmental benefits of using inert gases in furnaces? Reduce Waste and Emissions for a Greener Process