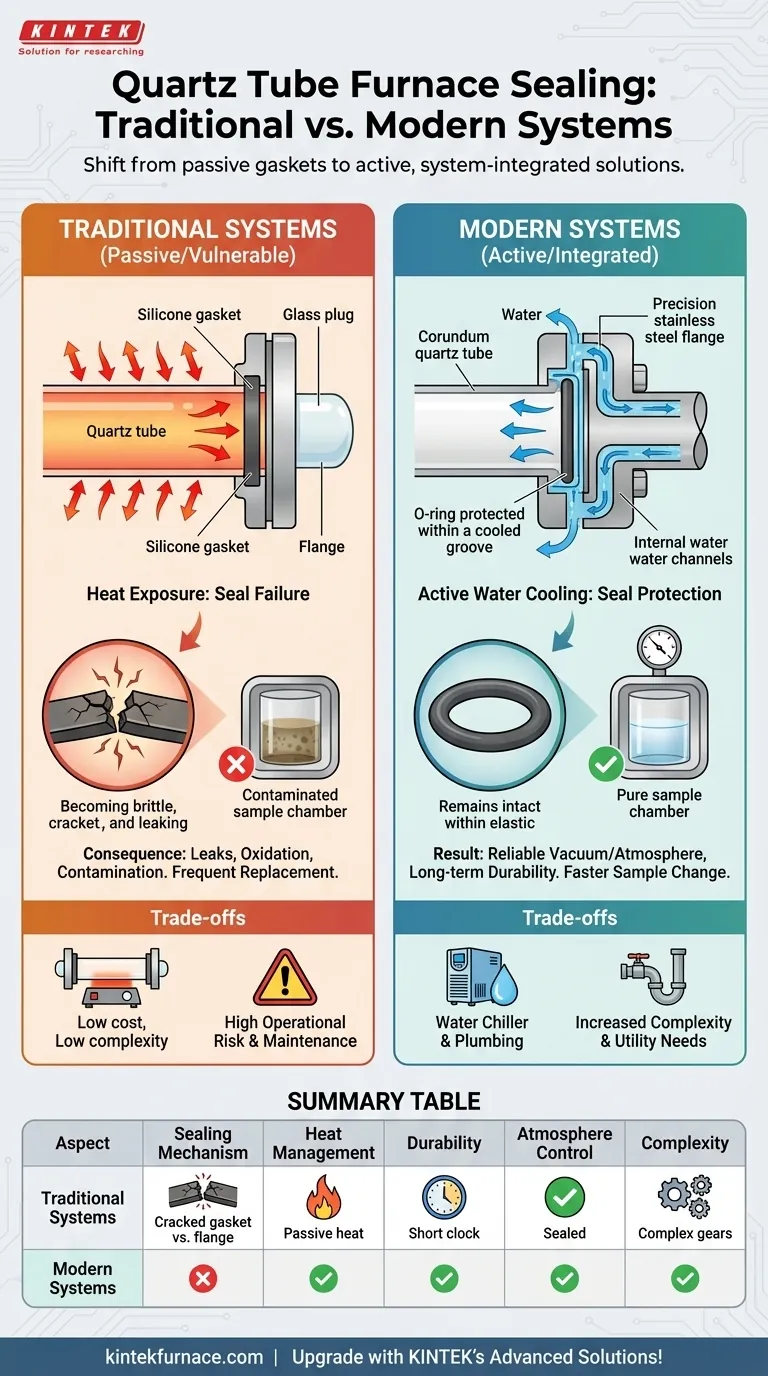

The fundamental difference in quartz tube furnace sealing lies in a shift from passive, heat-vulnerable gaskets to active, system-integrated solutions. Traditional furnaces rely on simple silicone seals that degrade over time, whereas modern designs use actively water-cooled stainless steel flanges. This approach protects the sealing element from heat, ensuring a reliable, long-term vacuum or controlled atmosphere.

The core issue isn't the seal itself, but how the furnace system manages heat at the sealing point. Traditional systems allow heat to destroy the seal, while modern systems actively remove that heat to preserve atmospheric integrity.

The Core Problem with Traditional Sealing

Older furnace designs often treated the seal as a simple, replaceable component. This approach created a persistent point of failure that could compromise sensitive processes.

The Inevitable Failure of Silicone Gaskets

In traditional setups, a silicone gasket is compressed between the quartz tube and a plug. While simple, this places the silicone perilously close to the hot zone.

Even with some distance, heat inevitably conducts and radiates to the seal. This thermal exposure causes the silicone to harden, become brittle, and crack, leading to a loss of sealing pressure.

The Consequence: A Compromised Atmosphere

A failed seal means the controlled atmosphere inside the tube is no longer isolated. This can lead to oxygen leaks that cause unwanted oxidation, or contamination from the ambient air, rendering experiments and production runs useless. This constant risk requires frequent maintenance and seal replacement.

The Modern Approach: An Integrated Sealing System

Modern quartz tube furnaces address this problem not with a better gasket, but with a smarter overall system design that protects the seal from heat entirely.

Active Water Cooling

The defining feature is a water-cooled flange assembly. A dedicated channel within the stainless steel flange circulates water, typically kept around 20°C.

This active cooling acts as a thermal barrier, continuously drawing heat away from the sealing area. The gasket or O-ring, now protected within the cool flange, is never exposed to damaging temperatures, allowing it to maintain its elasticity and sealing capability indefinitely.

Robust Flange and Tube Design

This system moves away from simple glass plugs. Instead, it utilizes robust components like corundum quartz tubes paired with precisely machined stainless steel pipe flanges.

This construction offers superior durability and a more reliable sealing surface than the older quartz glass tube and piston designs. It also makes the process of changing samples significantly faster and safer.

Improved Thermal Efficiency

As an added benefit, modern designs often feature double insulation on the furnace's outer wall. This works in concert with the sealed system to minimize heat loss, improving energy efficiency and temperature uniformity during the sintering or annealing process.

Understanding the Trade-offs

While the modern approach is superior for atmospheric integrity, it's important to recognize the associated complexities.

Increased System Complexity

An active water-cooling system introduces more components. It requires a water chiller or a steady supply of tap water, along with plumbing and flow-rate monitoring. This adds to the initial setup cost and introduces new maintenance considerations compared to a simple passive seal.

Utility Requirements

The need for a water circulator means the furnace has additional utility requirements beyond just power. This must be factored into lab space planning and operational costs. Forgetting to turn on the water flow can lead to rapid seal failure, though most systems have safety interlocks to prevent this.

Making the Right Choice for Your Process

The ideal sealing mechanism depends entirely on the sensitivity of your work and your operational priorities.

- If your primary focus is high-purity or oxygen-sensitive processes: The water-cooled flange system is essential for achieving reliable, repeatable results.

- If your primary focus is high throughput and ease of use: The robust flange design allows for quicker and safer sample replacement, significantly improving workflow efficiency.

- If your primary focus is minimizing initial cost for non-sensitive applications: A traditional system may be sufficient, but you must accept the ongoing risk and maintenance burden of seal degradation.

Ultimately, investing in a furnace with an advanced sealing system is an investment in the consistency and success of your results.

Summary Table:

| Aspect | Traditional Systems | Modern Systems |

|---|---|---|

| Sealing Mechanism | Silicone gaskets prone to heat degradation | Water-cooled stainless steel flanges with active cooling |

| Heat Management | Passive, allowing seal exposure to heat | Active cooling to protect seals from heat |

| Durability | Short lifespan, frequent replacements | Long-term reliability, minimal maintenance |

| Atmosphere Control | High risk of leaks and contamination | Consistent vacuum or controlled atmosphere |

| Complexity | Simple setup, low initial cost | Higher complexity, requires water utilities |

Upgrade your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all with deep customization to meet your unique experimental needs. Ensure precise, reliable results with our innovative sealing technologies—contact us today to discuss how we can enhance your processes!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide