The fundamental benefits of an alumina tube furnace stem from its unique combination of material purity and structural design. It provides an exceptionally stable and controlled environment for high-temperature material processing, ensuring both the integrity of the sample and the repeatability of the results. This makes it an indispensable tool for advanced research and specialized industrial applications.

An alumina tube furnace is not just a device for heating; it is a precision instrument. Its core value lies in creating a chemically pure, uniformly heated environment at extreme temperatures, which is a requirement for developing advanced materials and achieving reliable scientific data.

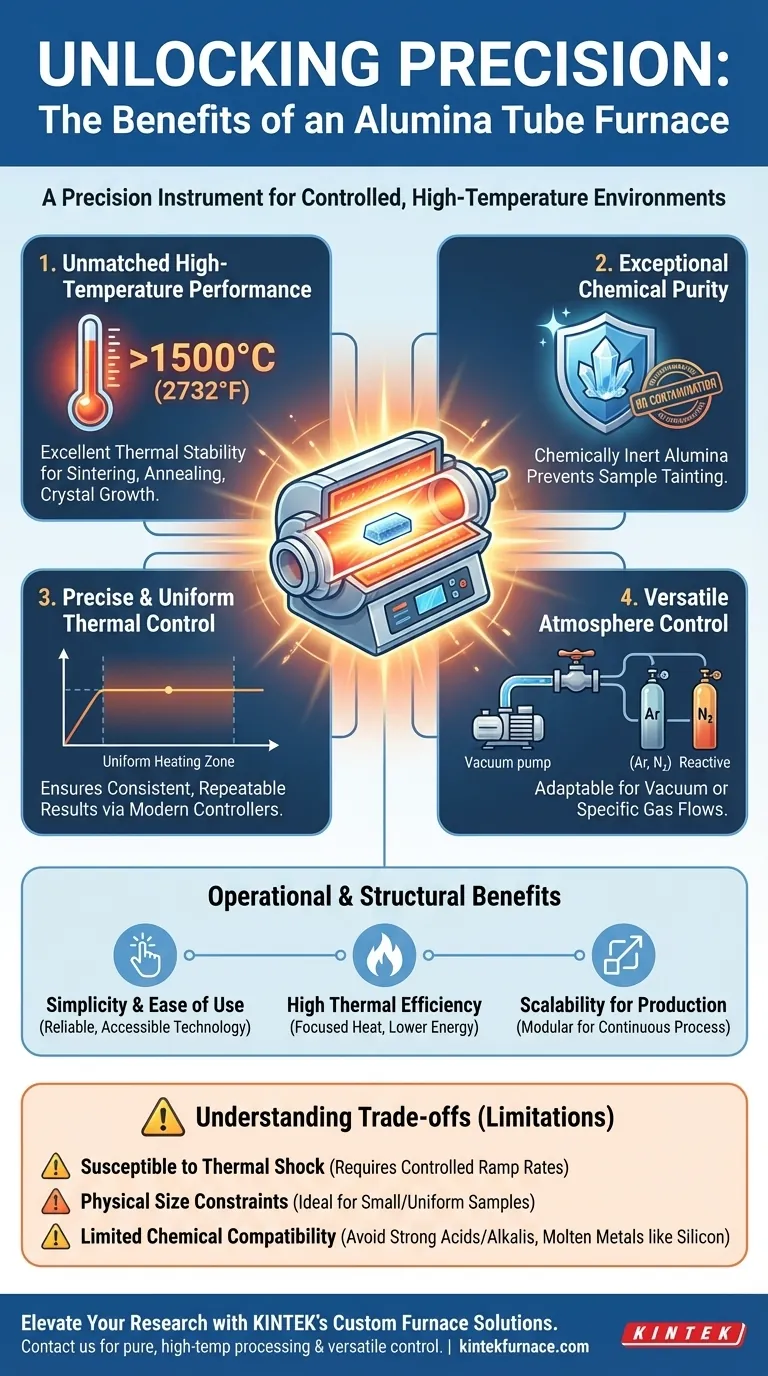

The Core Advantages Explained

The value of an alumina tube furnace comes from merging the superior properties of alumina ceramic with the controlled environment of a tube furnace design.

Unmatched High-Temperature Performance

The furnace's tube is made of high-purity alumina, a ceramic renowned for its excellent thermal stability.

This allows the furnace to operate consistently at very high temperatures, often exceeding 1500°C (2732°F). This capability is essential for processes like sintering advanced ceramics, annealing exotic alloys, and crystal growth.

Exceptional Chemical Purity

Alumina is chemically inert, meaning it does not easily react with other substances, even at high temperatures.

This chemical inertness is critical for preventing contamination of the sample being processed. It ensures that the results of an experiment or the final product are pure and not tainted by materials from the furnace itself.

Precise and Uniform Thermal Control

The tube furnace design creates a distinct, uniform heating zone in the center of the tube.

This ensures that the entire sample is exposed to the same temperature, which is vital for achieving consistent and repeatable results. Modern controllers allow for precise temperature programming, including specific ramp rates and dwell times.

Versatile Atmosphere Control

The sealed tube design is easily adaptable for controlling the gaseous environment around the sample.

You can create a vacuum or introduce a continuous flow of specific gases, such as inert gases (like argon or nitrogen) to prevent oxidation, or reactive gases to facilitate a specific chemical reaction. This versatility dramatically expands its range of applications.

Operational and Structural Benefits

Beyond its core scientific advantages, the alumina tube furnace is valued for its practical design and efficiency.

Simplicity and Ease of Use

Tube furnaces possess a relatively simple structure, making them straightforward to operate and maintain. This mature technology is well-understood, reliable, and accessible for both new and experienced technicians.

High Thermal Efficiency

The design concentrates heat directly around the sample within the tube, minimizing energy loss to the surrounding environment. This results in high thermal efficiency and lower power consumption compared to larger, less-focused furnace designs.

Scalability for Production

While often used in laboratories, the principle is scalable. Multiple tube furnaces can be combined and operated continuously to facilitate large-scale production for certain industrial processes.

Understanding the Trade-offs

No instrument is perfect for every task. To use an alumina tube furnace effectively, you must be aware of its limitations.

Susceptibility to Thermal Shock

Alumina is a ceramic and, like most ceramics, is brittle. Heating or cooling the tube too quickly can cause it to crack, an event known as thermal shock. Following the manufacturer's recommended ramp rates is absolutely critical to preserve the life of the tube.

Physical Size Constraints

By its nature, a tube furnace limits the physical dimensions of the sample you can process. It is ideal for small, uniform samples but is unsuitable for large or irregularly shaped objects, for which a box furnace might be a better choice.

Limited Chemical Compatibility

While alumina is highly inert, it is not completely immune to all chemicals. It can be attacked by certain strong acids, alkalis, and molten metals (like silicon) at very high temperatures. Always verify the compatibility of your specific process materials with alumina before use.

Making the Right Choice for Your Application

Selecting a furnace requires matching its strengths to your primary goal.

- If your primary focus is material purity: The chemical inertness of the alumina tube is your single most important benefit, preventing sample contamination.

- If your primary focus is extreme temperatures: The furnace's ability to operate stably above 1500°C is what enables work with advanced ceramics, refractories, and alloys.

- If your primary focus is process repeatability: The precise temperature control and uniform heating zone ensure that every sample is processed under identical conditions.

- If your primary focus is versatile research: The ability to easily control the atmosphere—from vacuum to reactive gases—makes it a workhorse for a wide range of material science experiments.

Ultimately, an alumina tube furnace empowers you to achieve precise control over the most demanding thermal processing applications.

Summary Table:

| Advantage | Key Feature | Benefit |

|---|---|---|

| High-Temperature Performance | Operates above 1500°C | Enables sintering, annealing, and crystal growth |

| Chemical Purity | Alumina inertness | Prevents sample contamination |

| Thermal Control | Uniform heating zone | Ensures consistent, repeatable results |

| Atmosphere Control | Vacuum and gas flow options | Supports diverse applications |

| Thermal Efficiency | Focused heating design | Reduces energy consumption |

| Scalability | Modular design | Facilitates large-scale production |

Unlock Precision in Your Lab with KINTEK's Custom Furnace Solutions

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you need pure, high-temperature processing or versatile atmosphere control, we deliver reliable, efficient tools to enhance your research and production.

Contact us today to discuss how our alumina tube furnaces can elevate your material science projects and achieve superior results!

Visual Guide

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- Why is uniform heating important in tubular furnaces? Ensure Process Reliability and Predictable Results

- What is a tubular furnace? Precision Heating for Lab and Industrial Applications

- What industries benefit from the use of tube furnaces? Unlock Precision in Semiconductor and Battery Tech

- What is flash vacuum pyrolysis and how is a tube furnace utilized in this process? Unlock High-Temp Chemical Reactions

- What materials are used for the tube chamber in tubular furnaces? Choose the Right Tube for Your Lab's High-Temp Needs