The high-temperature tube furnace serves as the foundational reaction vessel for converting natural biomass structures into advanced ceramic materials. It acts as a precise thermal reactor that first converts organic raw materials—such as wood or grain stalks—into porous carbon templates, and subsequently drives the chemical transformation into high-strength biomimetic silicon carbide (SiC) skeletons.

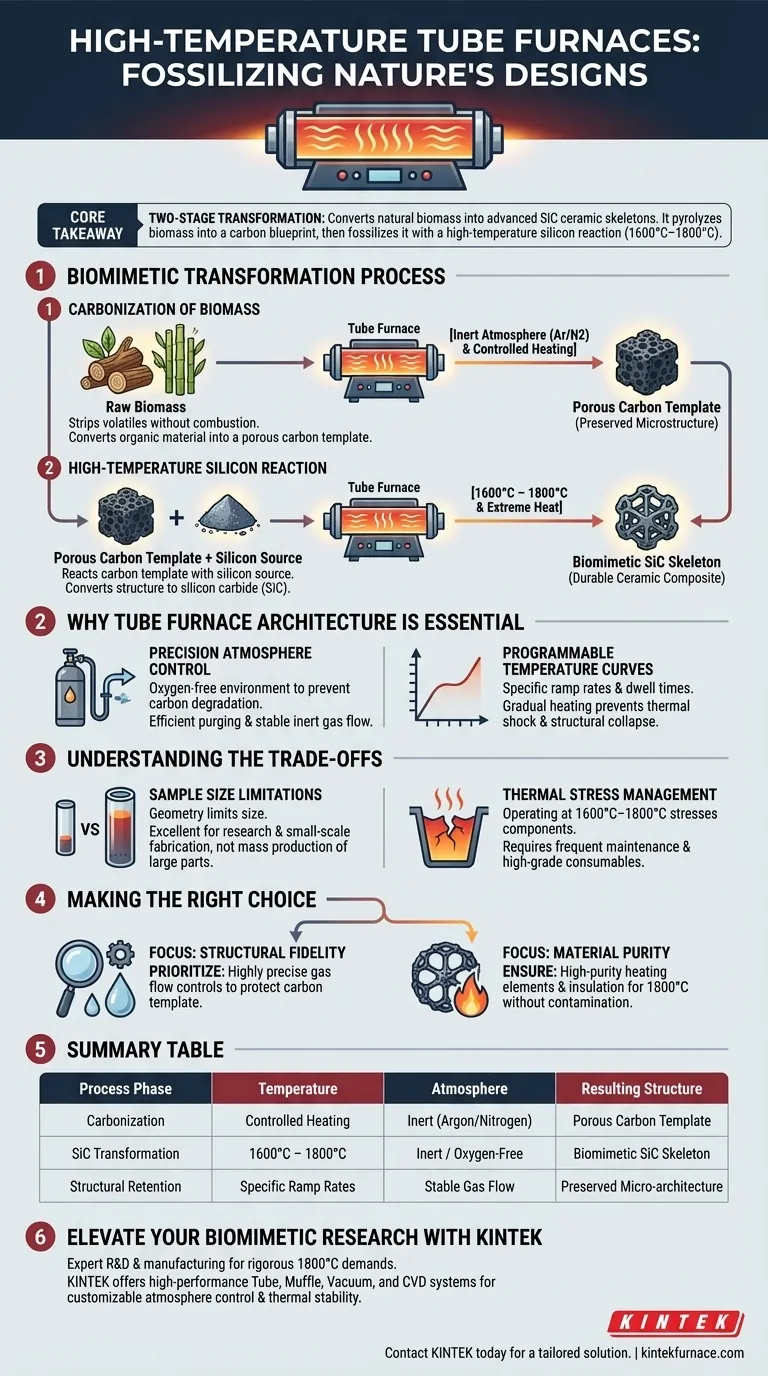

Core Takeaway The tube furnace enables a two-stage transformation: it first pyrolyzes biomass into a carbon blueprint under an inert atmosphere, then facilitates a high-temperature reaction (1600°C–1800°C) with a silicon source to fossilize the structure into a durable ceramic composite.

The Biomimetic Transformation Process

Step 1: Carbonization of Biomass

The initial role of the furnace is to strip away volatile components from the raw material.

By operating under a strictly controlled inert atmosphere, the furnace heats biomass like wood, fruit peels, or grain stalks without allowing them to combust.

This process converts the organic material into a porous carbon template, effectively preserving the intricate natural microstructure of the original plant.

Step 2: High-Temperature Silicon Reaction

Once the carbon template is created, the furnace's ability to reach extreme temperatures becomes critical.

The system is ramped up to temperatures between 1600°C and 1800°C to induce a chemical reaction.

At these temperatures, the carbon template reacts with a silicon source, converting the carbon structure into biomimetic silicon carbide (SiC) while retaining the original porous architecture.

Why the Tube Furnace Architecture is Essential

Precision Atmosphere Control

Creating biomimetic skeletons requires an oxygen-free environment to prevent the carbon template from turning into ash.

The tube design allows for the efficient purging of air and the maintenance of a stable inert gas flow (such as argon or nitrogen) throughout the multi-hour process.

Programmable Temperature Curves

Biomimetic synthesis is rarely a linear heating process; it requires specific ramp rates and dwell times.

The furnace controls precise temperature curves, ensuring the material is heated gradually to prevent thermal shock and structural collapse before the ceramic conversion is complete.

Understanding the Trade-offs

Sample Size Limitations

The geometry of a tube furnace inherently limits the size of the biomimetic skeleton you can produce.

Because the heat zone is defined by the diameter of the tube, this method is excellent for research and small-scale component fabrication but may require different furnace architectures for mass production of large parts.

Thermal Stress Management

Operating at 1600°C–1800°C places immense stress on heating elements and consumables.

While some advanced furnaces can reach 1900°C, consistent operation at the upper limits requires frequent maintenance and expensive, high-grade consumables (like crucibles) to avoid contaminating the pure SiC skeleton.

Making the Right Choice for Your Goal

To maximize the quality of your biomimetic composites, align your furnace operation with your specific objectives:

- If your primary focus is Structural Fidelity: Prioritize a furnace with highly precise gas flow controls to ensure the carbon template does not degrade before silicon infiltration.

- If your primary focus is Material Purity: Ensure your furnace utilizes high-purity heating elements and insulation capable of sustaining 1800°C without outgassing contaminants.

Success in biomimetic synthesis relies not just on reaching high temperatures, but on the precise orchestration of atmosphere and heat to fossilize nature’s designs.

Summary Table:

| Process Phase | Temperature Range | Atmosphere Requirement | Resulting Structure |

|---|---|---|---|

| Carbonization | Controlled Heating | Inert (Argon/Nitrogen) | Porous Carbon Template |

| SiC Transformation | 1600°C – 1800°C | Inert / Oxygen-Free | Biomimetic SiC Skeleton |

| Structural Retention | Specific Ramp Rates | Stable Gas Flow | Preserved Micro-architecture |

Elevate Your Biomimetic Research with KINTEK

Precision is the difference between a structural collapse and a perfect ceramic replica. Backed by expert R&D and manufacturing, KINTEK offers high-performance Tube, Muffle, Vacuum, and CVD systems specifically designed to handle the rigorous 1800°C demands of biomimetic synthesis. Whether you are fossilizing natural structures or developing next-gen composites, our customizable lab high-temp furnaces provide the atmosphere control and thermal stability your research requires.

Ready to optimize your thermal processing? Contact KINTEK today for a tailored solution.

Visual Guide

References

- Min Yu, Dou Zhang. Review of Bioinspired Composites for Thermal Energy Storage: Preparation, Microstructures and Properties. DOI: 10.3390/jcs9010041

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What critical experimental conditions does a tube furnace provide for carbonizing PI-COFs? Master Thermal Precision

- How does a Horizontal Tubular Furnace contribute to the physical activation of sawdust-derived activated carbon?

- Why is high-temperature annealing in a tube furnace necessary for LaAlO3? Optimize TiO2 Thin Film Adhesion

- What are the methods for treating exhaust gas using a tube furnace? Safely Neutralize Hazards in Your Lab

- What is the specific role of a tube furnace in the pre-treatment of activated carbon catalysts? Precision Modification

- What factors influence the heating process in a tube furnace? Master Temperature Control and Efficiency

- How are tubular furnaces used in chemical synthesis? Unlock Precise Material Creation

- What is the uniform length of a tube furnace and what factors affect it? Maximize Your Lab's Thermal Precision