In chemical synthesis, a tubular furnace serves as a high-precision reactor, providing an isolated and meticulously controlled environment. It is not merely a source of heat; it is an instrument that allows chemists and material scientists to dictate the exact conditions—temperature, atmosphere, and processing time—under which chemical reactions and material transformations occur, making it indispensable for creating novel materials and chemicals.

The true value of a tubular furnace in synthesis lies not just in its ability to reach high temperatures, but in its capacity to create an ultra-pure, controlled atmosphere. This control eliminates unwanted variables and enables the precise formation of materials that would be impossible to create in an open environment.

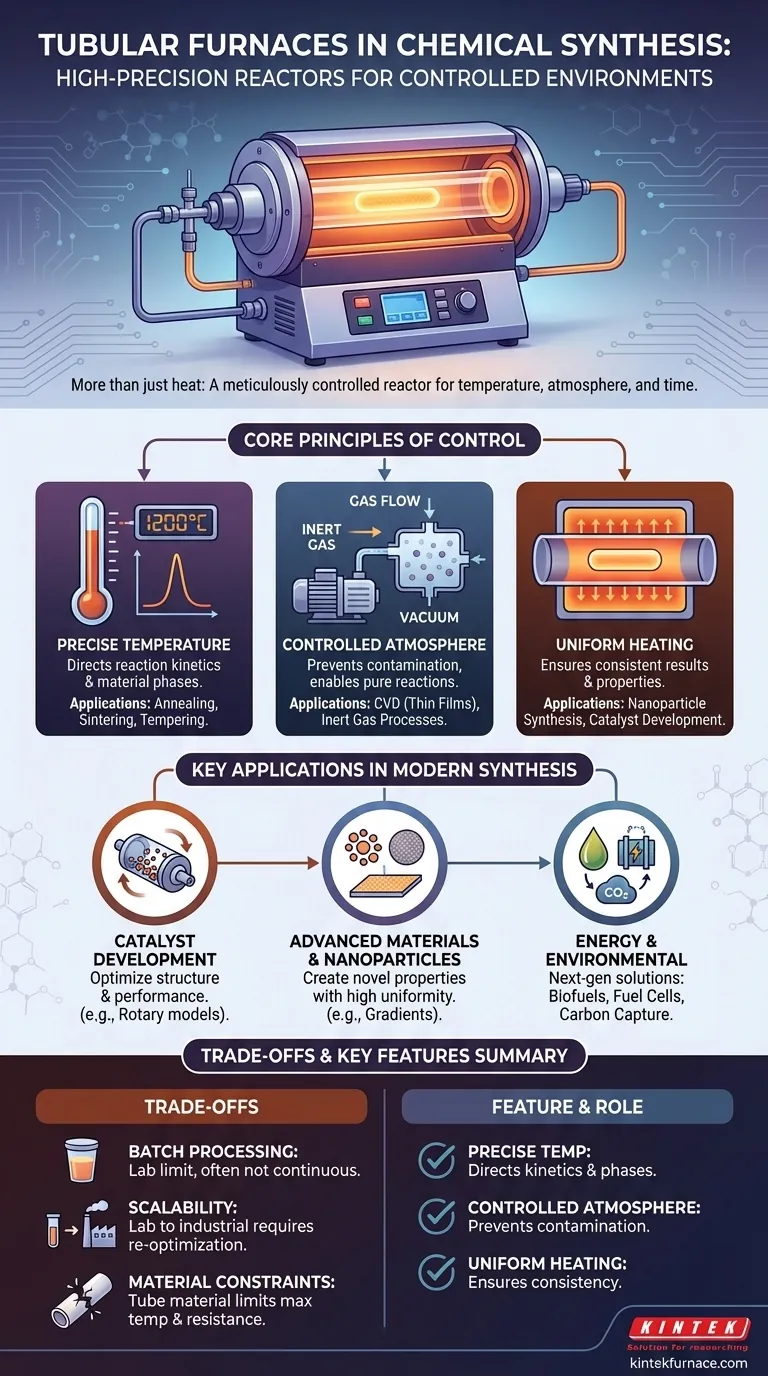

Why Control Is the Core Principle of Synthesis

The fundamental challenge in advanced synthesis is managing variables. A tubular furnace is designed specifically to give researchers command over the most critical factors influencing a chemical reaction's outcome.

Achieving Precise Temperature Control

Accurate temperature management is crucial for directing reaction kinetics and achieving desired material phases. Too low, and a reaction won't start; too high, and you risk decomposition or forming unwanted byproducts.

Furnaces provide this precision for processes like annealing, sintering, and tempering, where specific temperature profiles create the desired crystalline structure and material properties.

Managing the Reaction Atmosphere

Many modern materials are highly sensitive to oxygen or other atmospheric contaminants. A tube furnace can be evacuated to a high vacuum or filled with a specific inert or reactive gas.

This controlled atmosphere is the cornerstone of techniques like Chemical Vapor Deposition (CVD), where a pure environment prevents contamination and allows precursor gases to react cleanly on a substrate, forming high-purity thin films.

Ensuring Uniform Heating

The cylindrical geometry of a tube furnace ensures that the sample is heated evenly from all sides along a specific length. This temperature uniformity is critical for consistent results, whether you are heat-treating a small component or synthesizing a batch of powder.

This prevents hot spots or cold spots that could lead to an inconsistent product with varied material properties.

Key Applications in Modern Synthesis

The precise control offered by tubular furnaces has made them central to several cutting-edge research and production fields.

Catalyst Development

Researchers use tubular furnaces, especially rotary models, to study how processing parameters like gas composition and temperature affect a catalyst's final structure and performance. This allows for systematic optimization and rapid advancement in catalyst design.

Advanced Material and Nanoparticle Production

Tube furnaces are workhorses for creating materials with novel properties. In nanoparticle synthesis, a temperature gradient can be established along the tube to control particle growth and morphology with a high degree of uniformity.

Energy and Environmental Research

These furnaces are vital in developing next-generation energy and environmental solutions. Key applications include:

- Biomass Pyrolysis: Converting organic matter into biofuels in an oxygen-free environment.

- Fuel Cell Materials: Preparing and testing the specialized ceramics and metals used in fuel cells.

- Carbon Capture: Researching new materials and processes for capturing and storing CO2.

Understanding the Trade-offs

While powerful, a tubular furnace is a specialized tool with inherent limitations that are important to understand.

Batch vs. Continuous Processing

Most standard laboratory tube furnaces are designed for batch processing. A sample is loaded, processed, and then removed. While some designs like rotary furnaces allow for a more continuous flow of powders, they are not suited for the high-throughput liquid-phase synthesis common in other areas of chemistry.

Scalability Challenges

A process perfected in a one-inch diameter lab furnace may not scale directly to a large industrial reactor. The thermal dynamics, gas flow, and surface-area-to-volume ratio change significantly with size, often requiring a complete re-optimization of the process for production scale.

Material and Temperature Constraints

The furnace's capabilities are ultimately limited by its components. The process tube material—typically quartz, alumina, or mullite—determines the maximum operating temperature and its chemical resistance to the materials being synthesized. This choice dictates the range of possible applications.

Making the Right Choice for Your Synthesis Goal

The optimal use of a tubular furnace depends entirely on your end goal.

- If your primary focus is creating high-purity thin films: A furnace configured for Chemical Vapor Deposition (CVD) is essential for its superior atmosphere control.

- If your primary focus is developing novel catalysts or powders: A rotary tube furnace will ensure every particle is processed uniformly, leading to more consistent and reliable test results.

- If your primary focus is exploring fundamental material properties: A standard, single-zone tube furnace offers a flexible platform for testing how different temperatures and atmospheres impact a material's structure.

Ultimately, the tubular furnace is a cornerstone of modern materials science, empowering you to move from theoretical design to tangible innovation.

Summary Table:

| Feature | Role in Chemical Synthesis | Key Applications |

|---|---|---|

| Precise Temperature Control | Directs reaction kinetics and material phases | Annealing, sintering, tempering |

| Controlled Atmosphere | Prevents contamination, enables pure reactions | Chemical Vapor Deposition (CVD), inert gas processes |

| Uniform Heating | Ensures consistent results and material properties | Nanoparticle synthesis, catalyst development |

| Scalability Considerations | Batch processing limits, requires re-optimization for scale | Lab research vs. industrial production |

Ready to elevate your chemical synthesis with precision and control? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you're developing catalysts, producing nanoparticles, or advancing energy research, we can tailor a solution to enhance your results. Contact us today to discuss how our furnaces can drive your innovations forward!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis