The tube furnace functions as the critical reactor for precise thermal oxidation, serving as the mechanism that converts recovered lead powder into high-value industrial materials. It provides a controlled, high-temperature environment specifically regulated to 700°C, which is necessary to transform metallic lead into high-purity yellow orthorhombic lead oxide ($\beta$-PbO Massicot).

The tube furnace is the defining instrument for quality control in lead recovery; it ensures complete powder conversion and crystal structure stability through a rigorous two-step heating process.

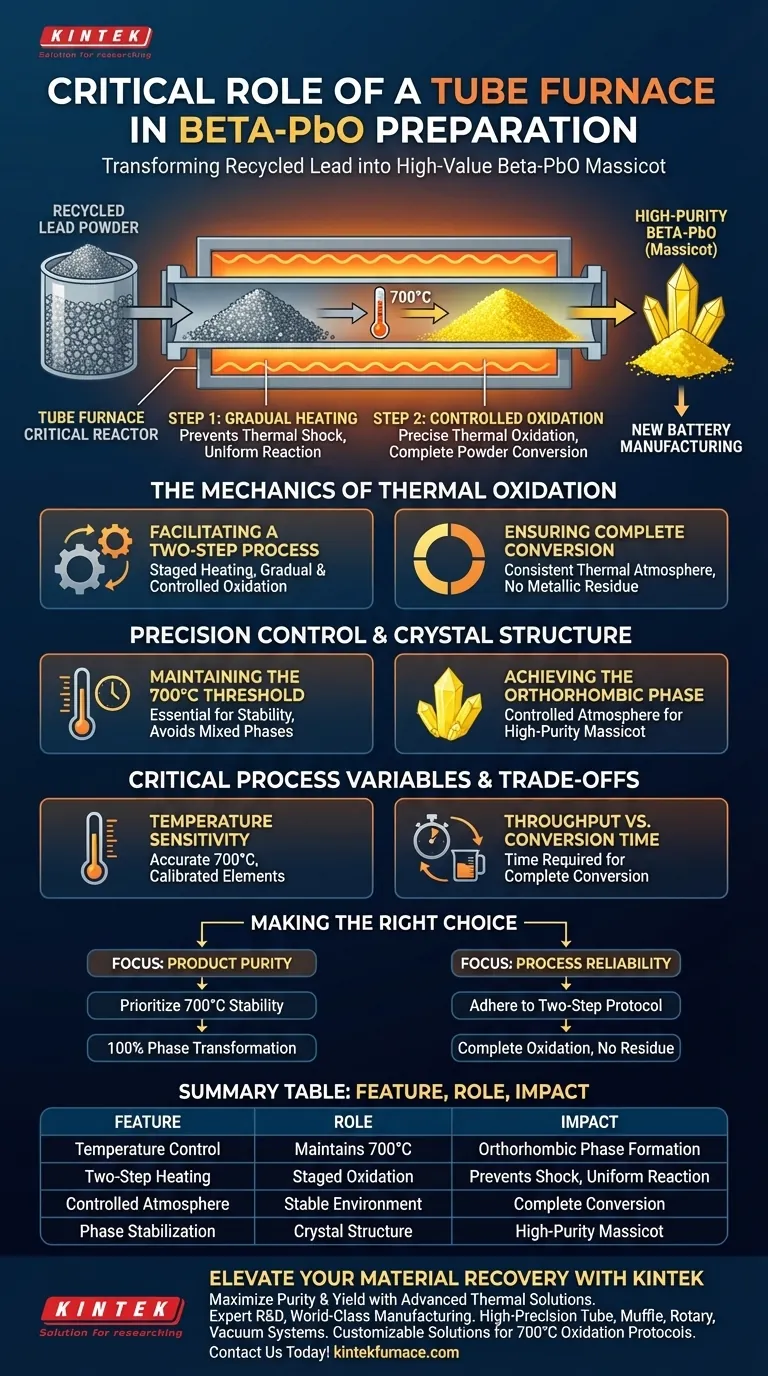

The Mechanics of Thermal Oxidation

To understand the furnace's role, one must look beyond simple heating. It acts as a stabilizer for chemical phase changes during the recycling process.

Facilitating a Two-Step Process

The transformation of recycled lead is not instantaneous. The tube furnace enables a distinct two-step heating process.

This staged approach allows for the gradual and controlled oxidation of the material. It prevents thermal shock and ensures the reaction proceeds uniformly throughout the powder batch.

Ensuring Complete Conversion

One of the primary challenges in battery recycling is unreacted metallic lead. The tube furnace addresses this by maintaining a consistent thermal atmosphere.

This environment guarantees that the oxidation penetrates the material fully. The result is a complete conversion from raw recycled powder to synthesized oxide, leaving no metallic residue.

Precision Control and Crystal Structure

The value of the final product depends entirely on its crystalline form. The tube furnace is the tool used to dictate this structure.

Maintaining the 700°C Threshold

The specific target for producing $\beta$-PbO is 700 degrees Celsius. The tube furnace is essential because it can hold this specific temperature with high precision.

Fluctuations in temperature can lead to mixed phases or incomplete reactions. The furnace’s stability ensures the material remains in the correct thermal zone for the duration of the process.

Achieving the Orthorhombic Phase

Lead oxide exists in multiple forms, but the goal here is "yellow orthorhombic lead oxide," also known as Massicot.

The furnace's controlled atmosphere creates the conditions required for this specific crystal lattice to form. This stability creates a high-purity product suitable for reuse in new battery manufacturing.

Critical Process Variables and Trade-offs

While the tube furnace is the ideal tool for this application, the quality of the output is heavily dependent on operational precision.

Temperature Sensitivity

The process relies on hitting the 700°C mark accurately. Deviating from this temperature can result in the formation of unwanted oxide phases or incomplete oxidation.

Operators must ensure the furnace's heating elements and thermocouples are calibrated strictly to avoid producing off-spec powder.

Throughput vs. Conversion Time

The two-step heating process inherent to the tube furnace method requires time.

Rushing the material through the furnace to increase throughput often compromises the "complete powder conversion." You trade volume for purity, risking a product that contains unoxidized metallic lead.

Making the Right Choice for Your Goal

The tube furnace is the standard for producing high-quality $\beta$-PbO. However, how you utilize it depends on your specific recycling objectives.

- If your primary focus is Product Purity: Prioritize the stability of the 700°C setpoint to ensure a 100% phase transformation to yellow orthorhombic crystals.

- If your primary focus is Process Reliability: Adhere strictly to the two-step heating protocol to guarantee complete oxidation and eliminate metallic residues.

By leveraging the precise thermal environment of the tube furnace, you turn waste material into a stable, high-value commodity.

Summary Table:

| Feature | Role in Beta-PbO Preparation | Impact on Quality |

|---|---|---|

| Temperature Control | Maintains precise 700°C threshold | Ensures formation of orthorhombic phase |

| Two-Step Heating | Staged thermal oxidation | Prevents thermal shock; ensures uniform reaction |

| Controlled Atmosphere | Stable reaction environment | Guarantees complete powder conversion |

| Phase Stabilization | Crystalline structure management | Eliminates metallic residue for high-purity Massicot |

Elevate Your Material Recovery with KINTEK

Maximize the purity and yield of your recycled lead oxides with KINTEK’s advanced thermal solutions. Backed by expert R&D and world-class manufacturing, KINTEK offers high-precision Tube, Muffle, Rotary, and Vacuum furnace systems specifically designed for the rigorous demands of chemical synthesis and battery recycling. Whether you need a standard setup or a customizable system tailored to your unique 700°C oxidation protocols, we provide the stability and control your lab requires.

Ready to refine your lead recovery process? Contact us today to find your perfect furnace solution!

Visual Guide

References

- Amna Idrees, Mohsin Saleem. Transforming Waste to Innovation: Sustainable Piezoelectric Properties of Pb(Ti<sub><b>0.52</b></sub>Zr<sub><b>0.48</b></sub>)O<sub><b>3</b></sub> with Recycled β-PbO Massicot. DOI: 10.1021/acsomega.5c00071

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What role does an industrial-grade high-temperature tube furnace play in the two-step pyrolysis of Fe–Mn–N–C? Optimize Synthesis

- What is the core function of a high-temperature tube furnace in Pb SA/OSC construction? Precision Atomic Engineering

- What technical advantages do three-zone tube furnaces offer? Superior Temperature Control and Flexibility

- What is the function of a Quartz Tube Furnace in the dry thermal oxidation of silicon wafers? Enhance Your Oxide Quality

- How does a laboratory tube diffusion furnace facilitate pre-deposition? Precision Doping for Silicon Wafer Processing

- What factors influence the processing time in a rotary tube furnace? Master Control for Efficient Heat Treatment

- What is the academic use of drop tube furnaces? Unlock Precise High-Temp Research for Materials and Energy

- What are the space-saving benefits of a tube furnace? Maximize Lab Efficiency with Compact Design