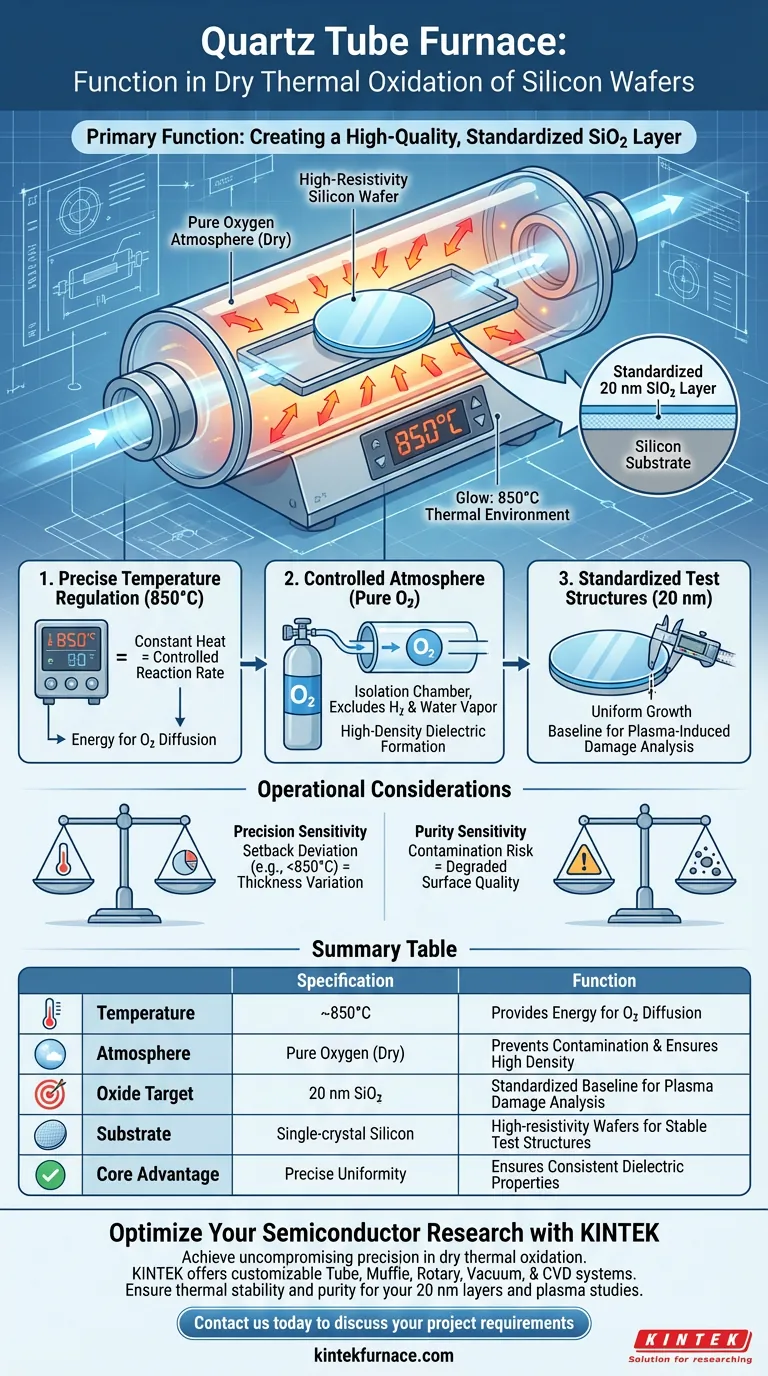

The primary function of a Quartz Tube Furnace in this context is to provide a strictly controlled environment for growing a high-quality thermal oxide (SiO2) layer on single-crystal silicon wafers. By maintaining a precise temperature of approximately 850°C in a pure oxygen atmosphere, the furnace facilitates the chemical reaction necessary to create a uniform, standardized oxide layer. This process is a critical prerequisite for advanced analysis, such as studying plasma-induced damage mechanisms.

In dry thermal oxidation, the Quartz Tube Furnace acts as a high-precision reactor that combines stable heat and pure oxygen to grow a standardized 20 nm SiO2 layer, serving as a reliable baseline for evaluating silicon wafer properties.

The Mechanics of Oxide Growth

Precise Temperature Regulation

The core capability of the Quartz Tube Furnace is its ability to maintain a rigorous thermal environment, typically centered around 850°C.

This specific high-temperature setting provides the energy required for oxygen molecules to diffuse into the silicon surface.

Consistent heat is vital to ensure the reaction proceeds at a controlled rate across the entire wafer.

Controlled Atmosphere Creation

The "dry" in dry thermal oxidation refers specifically to the use of a pure oxygen atmosphere within the tube.

The quartz tube serves as an isolation chamber, protecting the high-resistivity silicon wafers from external contaminants.

By excluding hydrogen or water vapor, the furnace ensures the formation of a dense, high-quality dielectric layer.

Creating Standardized Test Structures

Ensuring Uniformity

For research into sensitive topics like plasma-induced damage, the physical dimensions of the test structure must be exact.

The furnace allows for the uniform growth of the oxide layer, typically targeting a precise thickness of 20 nm.

This uniformity ensures that any variations observed in later testing are due to the experimental variables, not defects in the initial wafer structure.

High-Quality Dielectric Formation

The interaction between single-crystal silicon and pure oxygen creates a superior interface compared to other methods.

This results in a robust thermal oxide (SiO2) layer that is electrically stable.

Such stability is essential when using high-resistivity wafers for creating standardized initial structures.

Operational Considerations and Trade-offs

The Necessity of Precision

While the Quartz Tube Furnace yields high-quality results, it relies entirely on the stability of process parameters.

A deviation from the 850°C setpoint can alter the growth rate, leading to variations in the target 20 nm thickness.

Sensitivity to Purity

The advantage of using a pure oxygen atmosphere is lost if the environment is compromised.

The quartz tube must be maintained meticulously to prevent particulate contamination, which would degrade the quality of the single-crystal silicon surface.

Applying This to Your Process

To maximize the utility of a Quartz Tube Furnace for silicon wafer processing, align your operational controls with your specific outcomes:

- If your primary focus is Research Consistency: Strictly calibrate the furnace to 850°C to ensure the resulting 20 nm oxide layer is identical across all sample batches.

- If your primary focus is Defect Analysis: Prioritize the purity of the oxygen supply to rule out contamination as a source of damage during plasma studies.

By leveraging the precise environment of a Quartz Tube Furnace, you establish the fundamental baseline required for accurate semiconductor analysis.

Summary Table:

| Parameter | Specification | Function |

|---|---|---|

| Temperature | ~850°C | Provides energy for oxygen diffusion |

| Atmosphere | Pure Oxygen (Dry) | Prevents contamination and ensures high density |

| Oxide Target | 20 nm SiO2 | Standardized baseline for plasma damage analysis |

| Substrate | Single-crystal Silicon | High-resistivity wafers for stable test structures |

| Core Advantage | Precise Uniformity | Ensures consistent dielectric properties across batches |

Optimize Your Semiconductor Research with KINTEK

Achieve uncompromising precision in your dry thermal oxidation processes with KINTEK’s industry-leading thermal solutions. Backed by expert R&D and manufacturing, KINTEK offers high-performance Tube, Muffle, Rotary, Vacuum, and CVD systems—all fully customizable to meet your unique laboratory requirements.

Whether you are growing 20 nm oxide layers or conducting advanced plasma-induced damage studies, our equipment ensures the thermal stability and purity your research demands. Contact us today to discuss your project requirements and see how our expert-engineered furnaces can elevate your material analysis.

Visual Guide

References

- Shota Nunomura, Masaru Hori. O2 and Ar plasma processing over SiO2/Si stack: Effects of processing gas on interface defect generation and recovery. DOI: 10.1063/5.0184779

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What are common uses of tube furnaces? Precision Heating for Material Synthesis and Control

- How do industrial-grade tube furnaces facilitate the preparation of high-stability perovskites? Enhance Phase Purity

- What is the difference between a tube furnace and a box furnace? Choose the Right Tool for Your Lab

- How does a horizontal tube furnace work? Master Precise Thermal Processing for Your Lab

- What core physical conditions does a tube furnace provide in the two-step synthesis of WS2? Master Film Growth

- What is the necessity of using high-temperature tube furnaces for annealing? Master Quantum Emitter Fabrication

- What are the key features of a quartz tube furnace? Discover High-Temp Precision for Your Lab

- Why is alumina ceramic tubing selected as the liner for a Drop Tube Furnace? Ensure Purity and High-Temp Stability