From a technical standpoint, three-zone tube furnaces offer significant advantages over single-zone models primarily due to their superior temperature uniformity, process flexibility, and advanced control. By dividing the heated chamber into three independently controlled sections, these furnaces can create either an exceptionally uniform temperature profile across a longer area or a precise, intentional temperature gradient—capabilities a single-zone furnace cannot match.

The decision between a single-zone and a three-zone furnace is a choice between simplicity and precision. While a single-zone furnace is adequate for basic uniform heating, a three-zone furnace provides the control necessary for creating either longer, more stable uniform heat zones or complex temperature gradients, which is critical for advanced materials processing and research.

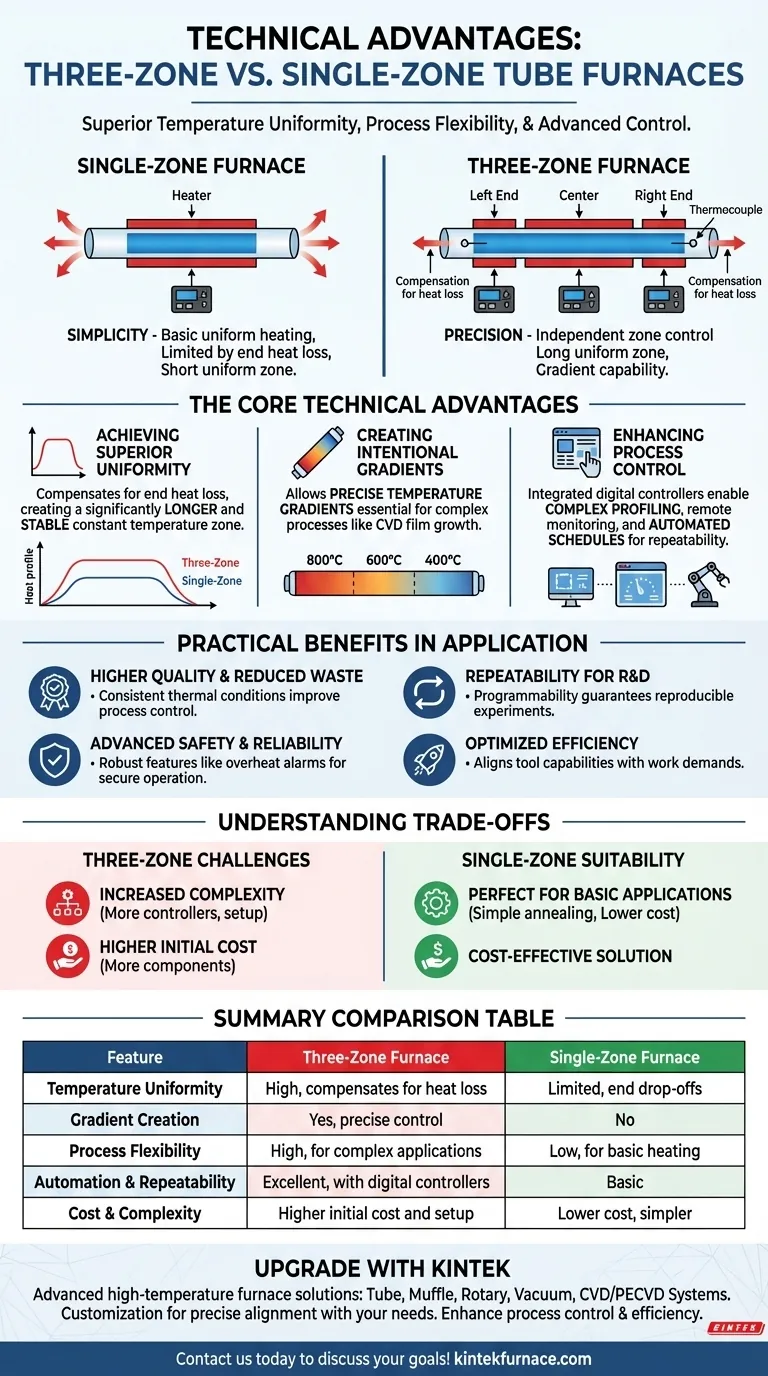

The Core Advantage: Independent Zone Control

The fundamental difference is the architecture. A single-zone furnace has one controller and one set of heating elements. A three-zone furnace has a central zone and two end zones, each with its own thermocouple and controller.

Achieving Superior Temperature Uniformity

In any tube furnace, heat naturally escapes from the ends. A single-zone furnace cannot compensate for this, resulting in a temperature drop-off near the openings and a relatively short true uniform heat zone in the center.

A three-zone furnace solves this by allowing you to set the end zones to a slightly higher temperature. This actively counteracts the heat loss, creating a significantly longer and more stable constant temperature zone in the middle.

Creating Intentional Temperature Gradients

The independent control also unlocks a capability impossible with single-zone models: creating a precise temperature gradient. This is essential for processes like Chemical Vapor Deposition (CVD), where different temperature stages are required along the length of the tube for film growth.

Enhancing Process Control and Automation

Three-zone furnaces almost always feature integrated digital controllers. This allows for complex temperature profiling, remote monitoring, and automated run schedules. This level of process control ensures repeatability, which is essential for both research and manufacturing environments.

The Practical Benefits in Application

These technical advantages translate directly into better outcomes for a wide range of applications, from heat treatment and annealing to semiconductor manufacturing.

Higher Quality and Reduced Waste

The exceptional temperature uniformity ensures that an entire sample or batch is processed under the exact same thermal conditions. This improves process control, leading to better-quality, more consistent outputs and a reduction in material waste from failed runs.

Repeatability for Research and Manufacturing

For material testing or R&D, the ability to precisely replicate thermal conditions is paramount. The programmability and stability of a three-zone furnace guarantee that experiments are repeatable, a cornerstone of valid scientific and industrial work.

Advanced Safety and Reliability

These advanced systems typically include more robust safety features. Protections such as overheat alarms and thermocouple-break detection are standard, providing a more reliable and secure operating environment for long, unattended processes.

Understanding the Trade-offs

While technically superior, a three-zone furnace is not always the necessary choice. Understanding its trade-offs is key to making an objective decision.

Increased Complexity

With three controllers instead of one, the setup and programming are inherently more complex. Operators require a better understanding of the system to optimize the temperature profile for their specific needs.

Higher Initial Cost

The additional heating elements, controllers, and thermocouples make three-zone furnaces significantly more expensive than single-zone models of a similar size. This investment must be justified by the need for precision.

When a Single-Zone Is Sufficient

For many basic applications, such as simple annealing or tempering of small, non-critical parts where a slight temperature deviation at the ends is acceptable, a single-zone furnace is a perfectly adequate and more cost-effective solution.

Making the Right Choice for Your Application

Your decision should be driven entirely by the requirements of your process.

- If your primary focus is process precision and repeatability: The superior uniformity and control of a three-zone furnace are non-negotiable for high-quality, consistent results.

- If your primary focus is creating temperature gradients: Only a multi-zone furnace can achieve this, making it essential for applications like Chemical Vapor Deposition (CVD).

- If your primary focus is maximizing the length of the uniform heat zone: A three-zone furnace will provide a longer and more stable uniform zone than a single-zone furnace of the same heated length.

- If your primary focus is cost-effectiveness for basic heat treatment: A single-zone furnace offers a simpler, more affordable solution when absolute temperature uniformity is not the critical factor.

Ultimately, selecting the right furnace is about aligning the tool's capabilities with the precision your work demands.

Summary Table:

| Feature | Three-Zone Furnace | Single-Zone Furnace |

|---|---|---|

| Temperature Uniformity | High, with compensation for heat loss | Limited, with end drop-offs |

| Gradient Creation | Yes, precise control | No |

| Process Flexibility | High, for complex applications | Low, for basic heating |

| Automation & Repeatability | Excellent, with digital controllers | Basic |

| Cost & Complexity | Higher initial cost and setup | Lower cost, simpler |

Upgrade your lab's capabilities with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored options like Tube Furnaces, Muffle Furnaces, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, enhancing process control and efficiency. Contact us today to discuss how we can support your research and manufacturing goals!

Visual Guide

Related Products

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What supplementary features can enhance rotary tube furnace performance? Boost Efficiency with Precision Control

- What are the main structural components of a rotary furnace? Explore Key Parts for Efficient Material Processing

- How do rotary tube furnaces achieve precise temperature control? Master Uniform Heating for Dynamic Processes

- What materials can be used to make the rotating tube assembly of these furnaces? Choose the Best for Your High-Temp Needs

- What are the common approaches to mixing in rotary furnaces? Boost Uniformity and Efficiency in Thermal Processing