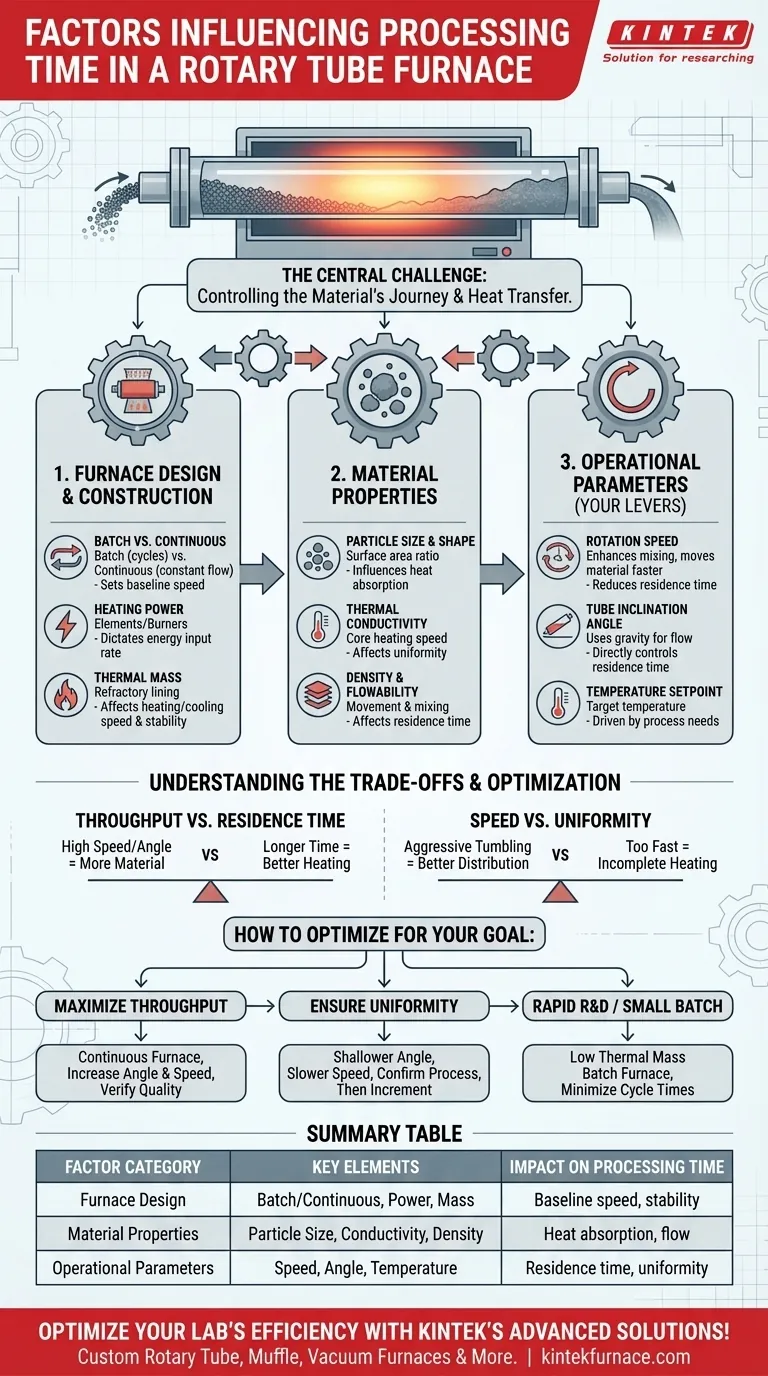

In short, processing time in a rotary tube furnace is determined by three core factors: the furnace's fundamental design, the inherent properties of the material being processed, and the operational parameters you control. For continuous systems, the most direct controls are the tube's rotation speed and its angle of inclination, which together dictate how long the material resides in the heat zone.

The central challenge is not just to heat material, but to control its journey. Processing time is a direct result of the balance you strike between the rate of heat transfer into the material and the duration it spends within the furnace, known as its residence time.

The Three Pillars of Processing Time

To truly master your process, you must understand how each of the three main factors contributes to the final result. They do not operate in isolation but interact continuously.

Pillar 1: Furnace Design and Construction

The physical characteristics of the furnace establish the baseline for its performance and speed.

-

Batch vs. Continuous Models A batch furnace requires a full heating and cooling cycle for every single load. A continuous furnace, by contrast, maintains its operating temperature while material is constantly fed and discharged, drastically reducing overall processing time for large quantities by eliminating these non-productive cycles.

-

Heating Method and Power The furnace's heat source—whether electric elements or gas burners—and its total power output dictate the maximum rate of energy input. A higher-power system can reach the target temperature faster and maintain it under a heavier load.

-

Thermal Mass The amount and type of refractory lining inside the furnace tube determine its thermal mass. A furnace with a heavy, dense lining will take longer to heat up and cool down but will hold its temperature more stably. A lighter furnace has less thermal inertia and can respond more quickly to temperature changes.

Pillar 2: Material Properties

The material you are processing is not a passive variable. Its physical and chemical nature has a profound impact on how quickly it can be treated.

-

Particle Size and Shape Finer powders have a much larger surface-area-to-volume ratio than large pellets or granules. This allows them to absorb heat much more rapidly and uniformly.

-

Thermal Conductivity Materials with high thermal conductivity will heat through to their core more quickly. Materials that are poor conductors (insulators) require a longer residence time to ensure the center of each particle reaches the target temperature.

-

Density and Flowability The bulk density and flow characteristics of your material will affect how it moves through the tube, influencing the mixing efficiency and the actual residence time at a given rotation speed and angle.

Pillar 3: Operational Parameters (Your Levers of Control)

These are the variables that you, the operator, can adjust to fine-tune the process in real time.

-

Rotation Speed Increasing the rotation speed enhances the tumbling and mixing of the material. This improves heat transfer uniformity but also tends to move the material through the furnace faster, reducing its residence time.

-

Tube Inclination Angle A steeper angle uses gravity to move material through the furnace more quickly, directly decreasing residence time. A shallower angle will increase the time the material spends in the heat zone.

-

Temperature Setpoint This is the target temperature for your process. While a higher temperature can often accelerate a chemical reaction or physical change, it is ultimately dictated by the requirements of your material and desired outcome.

Understanding the Trade-offs

Optimizing processing time is always an exercise in balancing competing factors. Speed is rarely the only goal.

Throughput vs. Residence Time

The most fundamental trade-off is between how much material you can process (throughput) and how long each particle is treated (residence time). Increasing rotation speed and inclination angle will boost throughput but may not give the material enough time to heat uniformly or for the desired reaction to complete.

Speed vs. Uniformity

Aggressively tumbling the material at high speed can improve heat distribution. However, if the material is also moving through the tube too quickly, particles may exit before they are uniformly heated to the core. The goal is uniform treatment, not just rapid movement.

How to Optimize Processing Time for Your Goal

Your strategy should be dictated by your primary objective. Use these guidelines to make an informed decision.

- If your primary focus is maximizing throughput: Prioritize a continuous furnace and carefully increase the inclination angle and rotation speed, while consistently verifying that the final product meets quality specifications.

- If your primary focus is ensuring process completion and uniformity: Begin with a shallower inclination angle and a slower rotation speed to maximize residence time, confirming the process works before incrementally increasing speed to find the optimal throughput.

- If your primary focus is rapid R&D or small batch production: Select a batch furnace with low thermal mass (lighter insulation) to minimize the time spent on heating and cooling cycles.

Ultimately, controlling processing time is about understanding and manipulating the flow of both heat and material to achieve a precise and repeatable result.

Summary Table:

| Factor Category | Key Elements | Impact on Processing Time |

|---|---|---|

| Furnace Design | Batch vs. Continuous, Heating Power, Thermal Mass | Sets baseline speed and stability |

| Material Properties | Particle Size, Thermal Conductivity, Density | Influences heat absorption and flow |

| Operational Parameters | Rotation Speed, Inclination Angle, Temperature | Directly controls residence time and uniformity |

Optimize your lab's efficiency with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored rotary tube furnaces, muffle furnaces, tube furnaces, vacuum & atmosphere furnaces, and CVD/PECVD systems. Our strong deep customization capability ensures precise solutions for your unique experimental needs, enhancing throughput and uniformity. Contact us today to discuss how we can elevate your heat treatment processes!

Visual Guide

Related Products

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

People Also Ask

- What are the main structural components of a rotary furnace? Explore Key Parts for Efficient Material Processing

- What is the basic construction of a rotary tube furnace? Key Components for Uniform Heating

- What materials can be used to make the rotating tube assembly of these furnaces? Choose the Best for Your High-Temp Needs

- What supplementary features can enhance rotary tube furnace performance? Boost Efficiency with Precision Control

- What factors should be considered when selecting a tube for a rotary tube furnace? Ensure Optimal Performance and Longevity