The primary function of a tube furnace in biomass carbonization is to create a strictly controlled, inert reaction environment that prevents combustion. By isolating materials like chestnut shells in an oxygen-free atmosphere—typically using argon or nitrogen—the furnace ensures the biomass does not burn to ash at high temperatures. Instead, it forces the material to undergo thermochemical decomposition, stripping away volatile components to leave behind a stable, restructured carbon skeleton.

A tube furnace serves as a precision reactor that decouples heat from combustion. It allows for the specific reorganization of carbon elements through dehydration and devolatilization, ensuring the final product preserves the intricate structural framework of the original biomass.

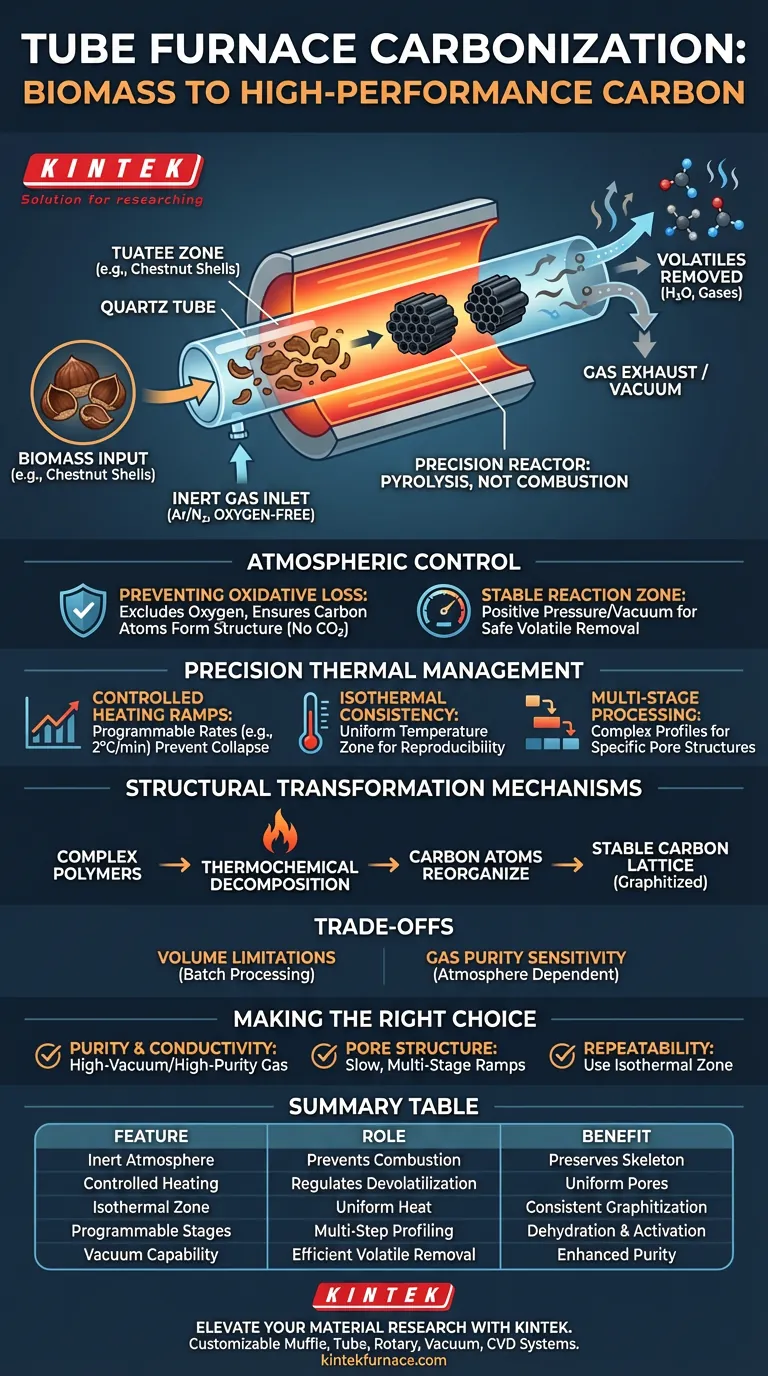

The Role of Atmospheric Control

Preventing Oxidative Loss

The most critical contribution of the tube furnace is the exclusion of oxygen. If biomass is heated in open air, it simply burns (oxidizes).

By sealing the material within a tube and purging it with inert gases like argon or nitrogen, the furnace facilitates pyrolysis rather than combustion. This ensures the carbon atoms remain to form the final structure rather than bonding with oxygen to form CO2.

Creating a Stable Reaction Zone

The furnace maintains a positive pressure of inert gas or a controlled vacuum. This environment is essential for the stability of the chemical changes occurring within the biomass.

It allows for the safe removal of volatile organic matter released during heating without risking uncontrolled ignition or contamination of the carbon structure.

Precision Thermal Management

Controlled Heating Ramps

Carbonization is not merely about reaching a high temperature; it is about how you get there. Tube furnaces allow for programmable heating rates (e.g., 2°C/min or 10°C/min).

This gradual heating is vital for orderly dehydrogenation. It prevents structural collapse that can occur if volatiles escape too quickly, ensuring the resulting carbon skeleton is hard and uniform.

Isothermal Consistency

Tube furnaces provide a distinct "isothermal zone"—a region where the temperature is perfectly constant.

Whether performing pre-carbonization at 350°C or graphitization at 1000°C, this consistency ensures that every particle of the chestnut shell powder experiences the exact same thermal history. This is key for ensuring reproducibility in experimental data and material performance.

Multi-Stage Processing

Advanced tube furnaces, particularly dual-zone models, allow for complex thermal profiles.

You can program the furnace to hold at a lower temperature to dehydrate the material, and then ramp up to a higher temperature for activation. This capability supports the formation of specific pore structures and high chemical stability in a single continuous process.

Structural Transformation Mechanisms

Thermochemical Decomposition

The heat provided by the furnace drives the breakdown of complex organic polymers found in biomass (cellulose, hemicellulence, and lignin).

Because the environment is controlled, this decomposition is selective. It effectively drives off hydrogen and oxygen in the form of water and gases, enriching the carbon content of the remaining solid.

Skeleton Reorganization

As the volatile matter leaves, the remaining carbon atoms reorganize. The tube furnace provides the energy required for these atoms to arrange themselves into a stable, conductive lattice.

This process transforms the raw biological structure of the chestnut shell into a graphitized carbon material suitable for high-performance applications like battery electrodes.

Understanding the Trade-offs

While tube furnaces offer unmatched precision, there are inherent limitations to consider.

Volume Limitations

Tube furnaces are generally batch-processing tools with limited sample capacity. The diameter of the tube restricts the volume of biomass you can carbonize at once, making them ideal for research or high-value production but less suitable for bulk industrial manufacturing.

Sensitivity to Gas Purity

The quality of the output is entirely dependent on the purity of the inert atmosphere. Even minor leaks or low-purity argon can introduce oxygen, leading to surface oxidation or "burn-off," which compromises the conductivity and structure of the final carbon material.

Making the Right Choice for Your Project

To maximize the effectiveness of a tube furnace for your specific biomass application, align your settings with your end goals.

- If your primary focus is material purity and conductivity: Prioritize a furnace with high-vacuum capabilities or high-purity argon flow to minimize oxygen exposure completely.

- If your primary focus is specific pore structure: Utilize the programmable heating rates to create a slow, multi-stage ramp that allows volatiles to escape without collapsing the pore walls.

- If your primary focus is experimental repeatability: Ensure your samples are placed strictly within the furnace's constant isothermal zone, avoiding the temperature gradients near the tube ends.

By leveraging the precise atmosphere and thermal controls of a tube furnace, you turn biological waste into a highly engineered carbon material.

Summary Table:

| Feature | Role in Carbonization | Benefit to Biomass Material |

|---|---|---|

| Inert Atmosphere | Prevents combustion/oxidation | Preserves carbon skeleton; avoids ash formation |

| Controlled Heating Ramp | Regulates devolatilization | Prevents structural collapse; ensures uniform pores |

| Isothermal Zone | Provides uniform heat distribution | Ensures consistent graphitization across samples |

| Programmable Stages | Multi-step thermal profiling | Enables dehydration and activation in one cycle |

| Vacuum Capability | Efficient removal of volatiles | Enhances purity and chemical stability of carbon |

Elevate Your Material Research with KINTEK

Transform biomass like chestnut shells into high-performance carbon materials with precision and ease. Backed by expert R&D and manufacturing, KINTEK offers a wide range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your unique carbonization and graphitization requirements. Whether you are aiming for specific pore structures or high-purity battery electrodes, our lab high-temp furnaces provide the thermal accuracy and atmospheric control you need to succeed.

Ready to optimize your pyrolysis process? Contact our experts today to find the perfect furnace solution for your lab.

Visual Guide

References

- Qian Wu, Yuanzheng Luo. Hierarchical porous biomass-derived electrodes with high areal loading for lithium–sulfur batteries. DOI: 10.1039/d5ra02380g

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- How do horizontal furnaces contribute to cost savings in industrial processes? Boost Efficiency & Cut Costs

- What are the key features of an atmosphere tube furnace? Unlock Precise Heat and Gas Control

- What is the purpose of using a resistance-heated tube furnace with inert gas? Protect Steel Integrity Today

- What is a split tube furnace and what makes it versatile? Unlock Easy Access and Flexibility for Your Lab

- What is the primary role of a tube furnace during pre-carbonization? Optimize Biomass-to-Hard-Carbon Conversion

- What materials are recommended for constructing a tube furnace for high temperatures? Essential Guide for Labs

- How does a High Temperature Tube Furnace maintain the desired temperature? Discover Precision Control for Your Lab

- What is a tubular heater used for? Prevent Frost and Damp with Low-Cost Maintenance Heat