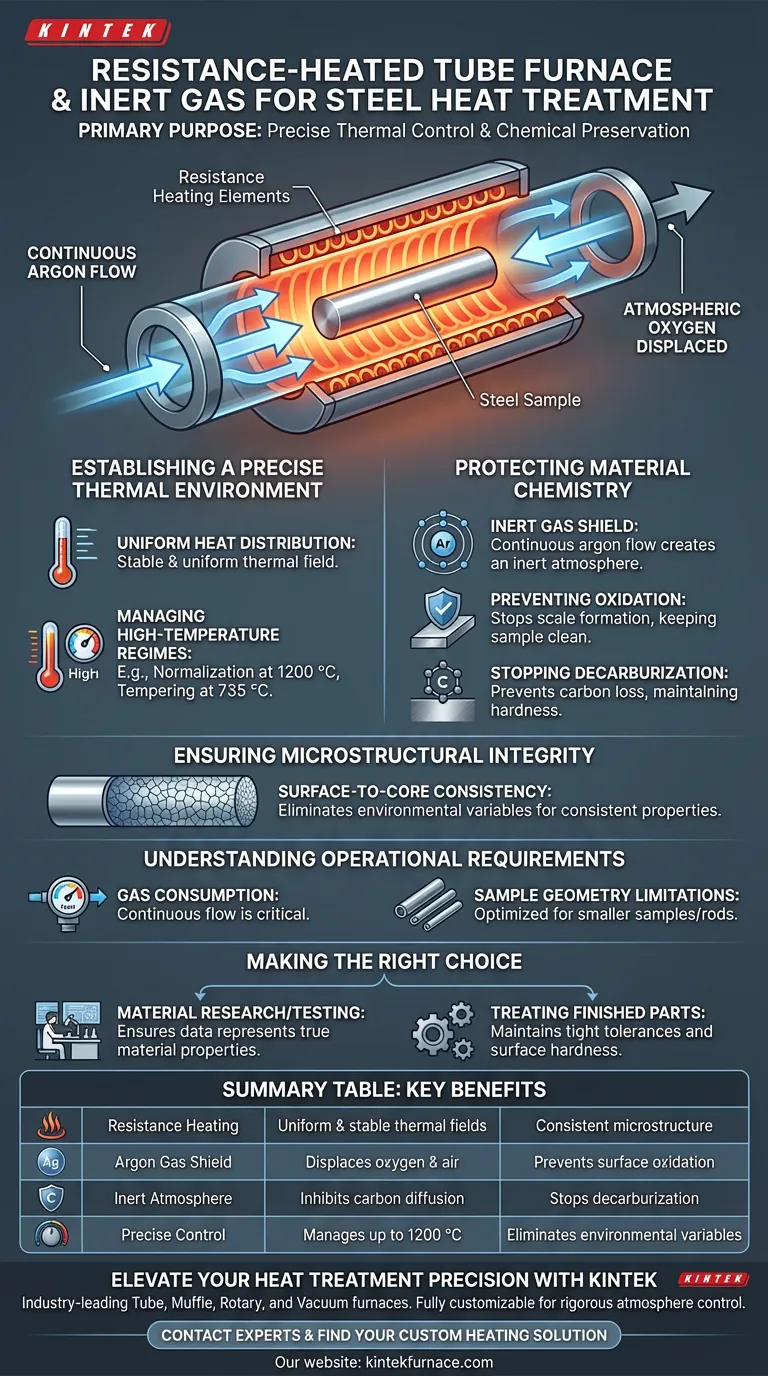

The primary purpose is twofold: precise thermal control and chemical preservation. A resistance-heated tube furnace with an inert gas system allows steel to undergo high-temperature treatments—such as normalization and tempering—without degrading its surface properties. This specific setup creates a controlled environment that isolates the material from atmospheric oxygen, ensuring that the physical changes in the steel are driven solely by temperature, not by unwanted chemical reactions.

By combining a stable thermal field with a continuous flow of argon, this setup effectively prevents surface defects, ensuring that the steel's microstructural characteristics remain consistent from the surface to the core.

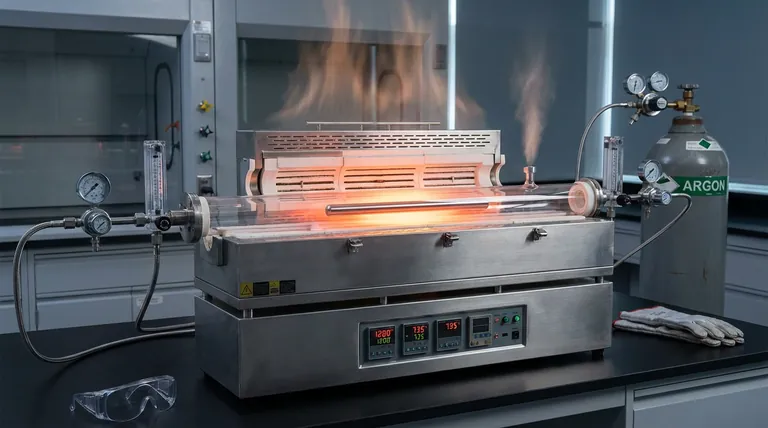

Establishing a Precise Thermal Environment

Uniform Heat Distribution

For heat treatment to be effective, the temperature must be consistent throughout the heating zone. A resistance-heated tube furnace is designed to provide a stable and uniform thermal field.

Managing High-Temperature Regimes

This equipment is capable of sustaining the extreme temperatures required for critical steel processing steps. It reliably handles processes such as normalization at 1200 °C and tempering at 735 °C without fluctuations that could alter the material's properties.

Protecting Material Chemistry

The Role of Inert Gas

High temperatures naturally accelerate chemical reactions between steel and air. The integration of a continuous-flow argon protection system displaces oxygen within the tube, creating an inert atmosphere around the sample.

Preventing Oxidation

Without protection, steel heated to these temperatures would react with oxygen to form scale (oxides) on the exterior. The argon shield effectively prevents surface oxidation, keeping the sample clean and dimensionally accurate.

Stopping Decarburization

Carbon is the most critical alloying element in steel; losing it changes the material's hardness and strength. The inert atmosphere prevents decarburization, a phenomenon where carbon atoms diffuse out of the steel surface into the atmosphere.

Ensuring Microstructural Integrity

Eliminating Variables

The ultimate goal of using this apparatus is to remove environmental variables from the heat treatment equation. By controlling the atmosphere, you ensure the results observed are due to the thermal cycle alone.

Surface-to-Core Consistency

When oxidation and decarburization are eliminated, the material properties at the surface match those at the center. This ensures that microstructural characteristics remain consistent between the surface and the core, which is vital for accurate testing and performance verification.

Understanding the Operational Requirements

Gas Consumption

The system relies on a continuous flow of argon to maintain the inert barrier. If the flow is interrupted or insufficient, atmospheric air can backstream into the tube, immediately compromising the sample.

Sample Geometry Limitations

While tube furnaces offer excellent uniformity, the physical geometry of the "tube" limits the size and shape of the steel samples that can be treated. This setup is generally optimized for smaller samples or rods rather than large, complex industrial parts.

Making the Right Choice for Your Goal

This setup is not merely about heating; it is about preserving the fidelity of the material during thermal stress.

- If your primary focus is material research or testing: This system is essential to ensure your data represents the true material properties, not surface defects or altered chemistry.

- If your primary focus is treating finished parts: Use this setup to maintain tight dimensional tolerances and surface hardness by preventing scale formation and carbon loss.

Ultimately, the resistance-heated tube furnace with inert gas protection is the standard for isolating thermal effects from chemical degradation.

Summary Table:

| Feature | Function in Steel Heat Treatment | Key Benefit |

|---|---|---|

| Resistance Heating | Provides uniform and stable thermal fields | Consistent microstructure from surface to core |

| Argon Gas Shield | Displaces oxygen and atmospheric air | Prevents surface oxidation and scale formation |

| Inert Atmosphere | Inhibits carbon diffusion out of the material | Stops decarburization and maintains surface hardness |

| Precise Control | Manages regimes up to 1200 °C (Normalization) | Eliminates environmental variables for accurate results |

Elevate Your Heat Treatment Precision with KINTEK

Don't let oxidation or decarburization compromise your material research. KINTEK provides industry-leading Tube, Muffle, Rotary, and Vacuum furnaces designed to deliver the rigorous atmosphere control your steel processing requires. Backed by expert R&D and manufacturing, our systems are fully customizable to meet your specific thermal and chemical preservation needs.

Ready to ensure surface-to-core consistency in your samples? Contact our experts today to find your custom heating solution.

Visual Guide

References

- Russell Goodall, Jack Haley. Development of a boron-containing reduced activation Ferritic-Martensitic (B-RAFM) steel. DOI: 10.1177/03019233241273484

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- Why are a high-temperature tube furnace and its reduction atmosphere control system core equipment for SrVO3?

- Why is a mixture of hydrogen and argon gas used during the annealing phase in a high-temperature tube furnace?

- Why are sealed quartz tubes required for TMD synthesis? Ensure Pure MoS2 & WS2 Growth

- What role does a high-vacuum tube furnace play in helium bubble studies? Master Thermal Activation & Material Purity

- How does a tube furnace facilitate the annealing process for Antimony-doped ZnSe and PbSe thin films? Key Performance Tips

- What function does a tube furnace perform in sintering boron duplex stainless steel? Master High-Precision Results

- Why is a continuous flow of high-purity nitrogen necessary during the pyrolysis of carbon materials in a tube furnace?

- How do high-temperature tube furnaces facilitate growth control in MoS2 LPCVD? Precision Synthesis Techniques