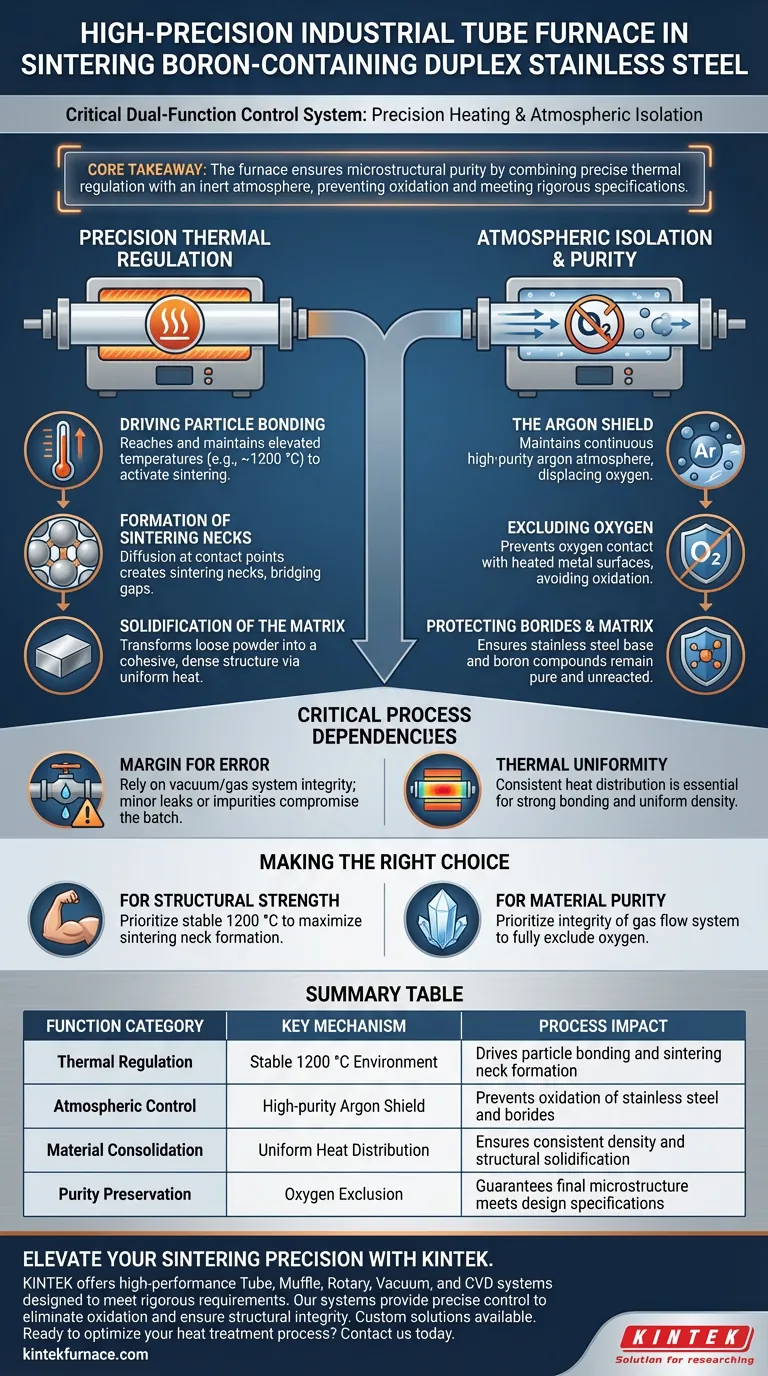

A high-precision industrial tube furnace acts as a critical dual-function control system during the sintering of boron-containing duplex stainless steel. Its primary mechanical function is to generate a stable high-temperature environment (typically around 1200 °C) that forces metal particles to bond by forming "sintering necks." Simultaneously, it serves as an isolation chamber, utilizing high-purity argon to strictly exclude oxygen and prevent chemical degradation.

Core Takeaway The furnace is not merely a heating device, but a tool for ensuring microstructural purity. By combining precise thermal regulation with an inert atmosphere, it prevents the oxidation of both the stainless steel matrix and borides, ensuring the material meets rigorous design specifications.

Precision Thermal Regulation

Driving Particle Bonding

The fundamental role of the furnace is to reach and maintain elevated temperatures, such as 1200 °C. This specific thermal energy is required to activate the sintering process.

Formation of Sintering Necks

At these temperatures, diffusion occurs at the contact points between individual powder particles. This results in the growth of sintering necks, which bridge the gaps between particles.

Solidification of the Matrix

The growth of these necks transforms the loose powder compact into a solid, cohesive structure. The precision of the furnace ensures this densification happens uniformly across the material.

Atmospheric Isolation and Purity

The Argon Shield

To protect the material, the furnace maintains a continuous atmosphere of high-purity argon. This inert gas fills the tube, effectively displacing standard atmospheric air.

Excluding Oxygen

The presence of oxygen at sintering temperatures would be catastrophic for stainless steel. The argon environment acts as a barrier, preventing oxygen from contacting the heated metal surfaces.

Protecting Borides and the Matrix

Both the stainless steel base and the boron compounds (borides) are highly susceptible to oxidation. The furnace’s atmospheric control ensures these elements remain pure and unreacted.

Ensuring Design Compliance

By preventing oxidation, the furnace guarantees that the final sintered microstructure is free of oxides. This purity is essential for the material to meet specific mechanical and design requirements.

Critical Process Dependencies

The Margin for Error

While high-precision furnaces offer control, they rely heavily on the integrity of the vacuum or gas system. Even a minor leak or impurity in the argon supply can compromise the entire batch.

Thermal Uniformity

The formation of sintering necks depends on consistent heat distribution. Any cold spots in the furnace tube will result in weak bonding and inconsistent material density.

Making the Right Choice for Your Goal

To ensure the successful sintering of boron-containing duplex stainless steel, prioritize the following operational parameters:

- If your primary focus is Structural Strength: Verify that the furnace can maintain a stable 1200 °C without fluctuation to maximize the formation of strong sintering necks.

- If your primary focus is Material Purity: Prioritize the integrity of the gas flow system to ensure the high-purity argon atmosphere completely excludes oxygen throughout the cycle.

The success of your sintering process depends on the furnace's ability to balance extreme heat with absolute atmospheric isolation.

Summary Table:

| Function Category | Key Mechanism | Process Impact |

|---|---|---|

| Thermal Regulation | Stable 1200 °C Environment | Drives particle bonding and sintering neck formation |

| Atmospheric Control | High-purity Argon Shield | Prevents oxidation of stainless steel and borides |

| Material Consolidation | Uniform Heat Distribution | Ensures consistent density and structural solidification |

| Purity Preservation | Oxygen Exclusion | Guarantees final microstructure meets design specifications |

Elevate Your Sintering Precision with KINTEK

Achieving the perfect balance of thermal uniformity and atmospheric purity is critical for advanced materials like boron-containing duplex stainless steel. Backed by expert R&D and manufacturing, KINTEK offers high-performance Tube, Muffle, Rotary, Vacuum, and CVD systems designed to meet your most rigorous lab and industrial requirements.

Our systems provide the precise control needed to eliminate oxidation and ensure structural integrity. Whether you need a standard model or a fully customizable solution for unique high-temp applications, KINTEK delivers the reliability your research deserves.

Ready to optimize your heat treatment process? Contact us today to find your custom furnace solution.

Visual Guide

References

- Microstructural Evolution of a Pre-Alloyed Duplex Stainless Steel 2205 with Boron Addition Prepared by Powder Metallurgy. DOI: 10.3390/powders4030024

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What are the types of vacuum tube furnaces based on? Key Classifications for Your Lab

- How do tube furnaces contribute to energy efficiency? Boost Your Lab's Performance with Advanced Thermal Solutions

- What are some common applications of tubular furnaces? Unlock Precision in High-Temperature Processing

- What are the primary functions of a tube furnace during GO thermal reduction? Optimize Graphene Conductivity

- How does an electric heating tube furnace ensure stable experimental conditions? Master Bio-Oil Upgrading Stability

- What role does an atmosphere tube furnace play in the thermal cyclization of PAN? Unlock High-Performance Electrodes

- How does treatment in a high-temperature tube furnace affect TiOx@C precursors? Engineering Oxygen Vacancies

- What core physical conditions does a tube furnace provide in the two-step synthesis of WS2? Master Film Growth