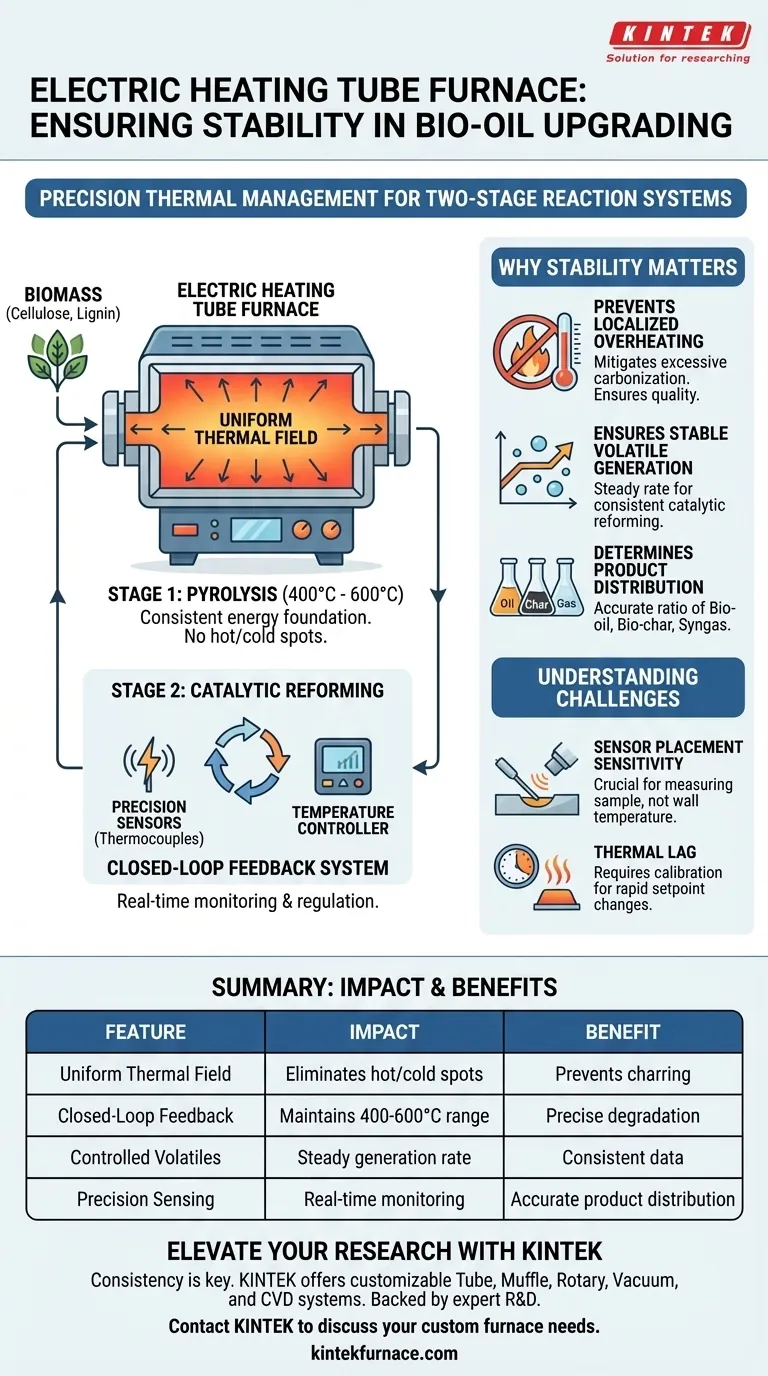

Precision thermal management is the cornerstone of effective bio-oil upgrading. An electric heating tube furnace ensures experimental stability through the integration of high-precision temperature controllers and real-time monitoring sensors. This hardware combination creates a uniform thermal field that spans both the initial pyrolysis reaction and the subsequent catalytic reforming stage, eliminating the temperature gradients that often lead to inconsistent data.

The core value of this system lies in its ability to prevent localized overheating. By maintaining a strictly controlled thermal environment, the furnace ensures the stable generation of volatiles without excessive carbonization, directly securing the quality of the final bio-oil product.

The Mechanics of Thermal Stability

Achieving a Uniform Thermal Field

The primary function of the electric heating tube furnace is to provide a consistent energy foundation for the reaction.

Unlike basic heating elements that may create hot or cold spots, this system generates a uniform thermal field distribution.

This uniformity is maintained across both stages of the process: the initial pyrolysis (thermal decomposition) and the catalytic reforming.

Precision Sensing and Feedback

Stability is achieved through a closed-loop system involving thermocouple sensors and temperature controllers.

These components work together to maintain a constant thermal environment, typically between 400°C and 600°C.

This specific range is critical for the effective thermochemical degradation of biomass components like cellulose, hemicellulose, and lignin.

Why Stability Matters for Bio-Oil Upgrading

Preventing Localized Overheating

One of the greatest risks in bio-oil production is "hot spots" within the reactor.

If the temperature spikes locally, it leads to excessive carbonization.

The electric heating tube furnace mitigates this by strictly regulating energy input, ensuring the biomass does not char prematurely before it can be converted into useful volatiles.

Ensuring Stable Volatile Generation

For a two-stage reaction to work, the first stage must feed the second stage consistently.

The furnace ensures that volatiles are generated at a steady rate within the set temperature range.

This stability allows the volatiles to move into the catalytic reforming stage with a consistent composition, which is essential for reliable experimental results.

Determining Product Distribution

The precision of the temperature control directly dictates the chemical outcome.

Minor fluctuations in heat can shift the reaction pathway, altering the ratio of bio-oil, bio-char, and syngas.

By locking in the temperature, the furnace ensures the final product distribution reflects the intended experimental parameters, not equipment error.

Understanding the Challenges

Sensor Placement Sensitivity

While the furnace is capable of precision, its accuracy relies heavily on sensor location.

If the thermocouple is not positioned correctly relative to the biomass sample, the controller may stabilize the furnace wall temperature rather than the sample temperature.

Thermal Lag

Electric heating systems provide excellent stability but may have slight delays in reaction time.

Rapidly changing the setpoint temperature during a run requires careful calibration to avoid overshooting or undershooting the target thermal field.

Making the Right Choice for Your Goal

To maximize the effectiveness of your bio-oil upgrading experiments, align your equipment settings with your specific objectives:

- If your primary focus is maximizing bio-oil yield: Prioritize the elimination of temperature spikes to prevent the biomass from degrading into bio-char.

- If your primary focus is reproducible data: Ensure your thermocouple sensors are calibrated and positioned to measure the reaction zone, not just the heating element.

Ultimately, the quality of your bio-oil is only as good as the stability of the thermal environment that created it.

Summary Table:

| Feature | Impact on Bio-Oil Upgrading | Benefit for Researchers |

|---|---|---|

| Uniform Thermal Field | Eliminates hot/cold spots across pyrolysis stages | Prevents excessive carbonization & charring |

| Closed-Loop Feedback | Maintains constant 400°C - 600°C range | Ensures precise thermochemical degradation |

| Controlled Volatiles | Steady generation rate for catalytic reforming | Consistent chemical composition & data |

| Precision Sensing | Real-time monitoring of reaction zones | Accurate product distribution (oil/char/gas) |

Elevate Your Bio-Oil Research with Precision Heating

Consistency is the difference between a failed experiment and a breakthrough. KINTEK provides industry-leading thermal solutions designed to meet the rigorous demands of biomass pyrolysis and catalytic reforming.

Backed by expert R&D and manufacturing, KINTEK offers Tube, Muffle, Rotary, Vacuum, and CVD systems, all of which are fully customizable to your specific temperature profiles and reactor geometries. Whether you need to eliminate thermal lag or ensure perfect sensor alignment for your two-stage reaction, our engineering team is ready to assist.

Ready to stabilize your experimental conditions? Contact KINTEK today to discuss your custom furnace needs and secure the quality of your final product.

Visual Guide

References

- Maryam Khatibi, Paul T. Williams. Pyrolysis/Non-thermal Plasma/Catalysis Processing of Refuse-Derived Fuel for Upgraded Oil and Gas Production. DOI: 10.1007/s12649-024-02866-w

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

People Also Ask

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- How does a tube atmosphere furnace facilitate local CVD during PAN fiber carbonization? Master In-Situ CNT Growth

- What role does an industrial-grade tube furnace play in Fe-P-NC catalyst pyrolysis? Precision Heating for Fe-P-NC Synthesis

- What role does a tube furnace play in the conversion of sludge into biochar? Master Precise Thermal Pyrolysis

- What technical requirements affect the external thermal strength of furnace tubes? Optimize for High-Temp Performance

- What is the function of a tube reduction furnace in PtLaOx@S-1 catalysts? Achieve Precise Chemical Restructuring

- What role does a tube furnace play in the high-temperature modification of La-EPS-C-450? Key Synthesis Insights

- Why is a tube furnace with argon required for Ti3AlC2 sintering? Protect Your High-Purity MAX Phase Synthesis