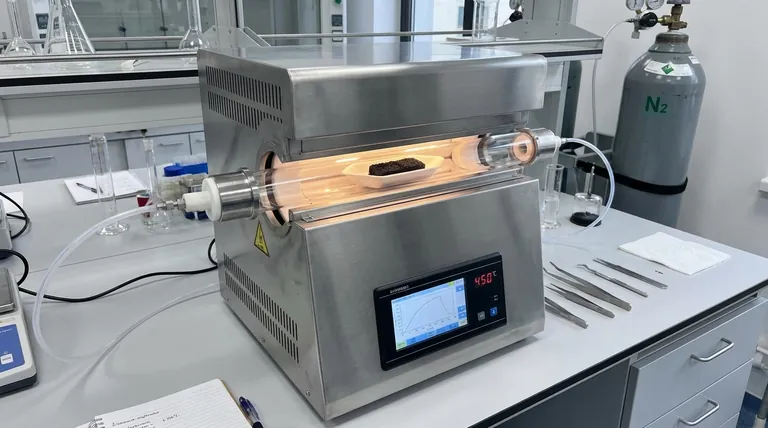

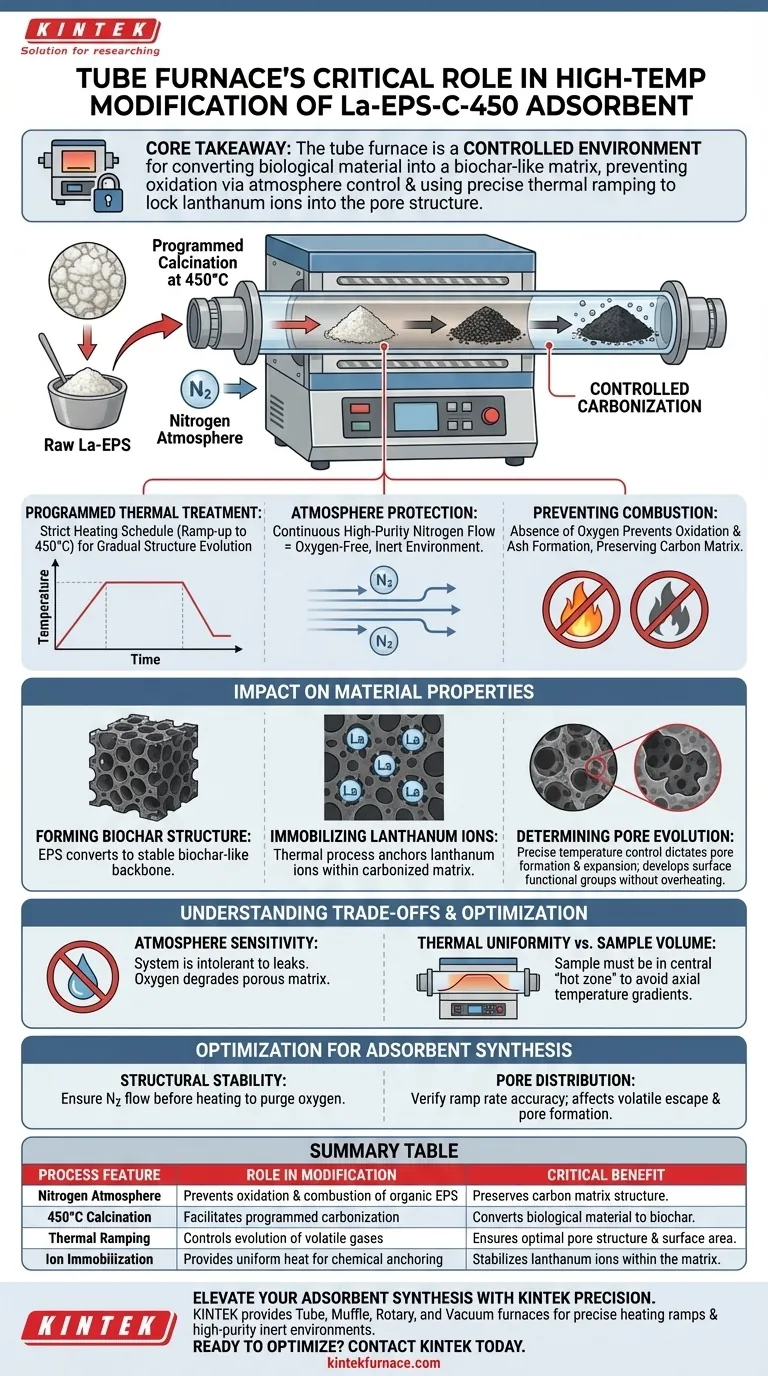

The tube furnace serves as the precise reaction vessel required to transform raw extracellular polymeric substances (EPS) into a stable, functionalized adsorbent. Specifically, it executes a programmed calcination at 450°C under a nitrogen atmosphere to facilitate carbonization without combustion.

Core Takeaway The tube furnace is not merely a heater; it is a controlled environment that enables the conversion of biological material into a biochar-like matrix. Its primary function is to prevent oxidation through atmosphere control while using precise thermal ramping to lock lanthanum ions into the developing pore structure.

The Mechanism of Controlled Carbonization

Programmed Thermal Treatment

The production of La-EPS-C-450 relies on a specific "programmed" temperature profile culminating at 450°C. The tube furnace follows a strict heating schedule rather than simply blasting the material with heat. This controlled ramp-up is critical for the gradual evolution of the material's structure.

Atmosphere Protection

The furnace operates under a continuous flow of high-purity nitrogen. This creates an oxygen-free, inert environment.

Preventing Combustion

If oxygen were present at these temperatures, the organic EPS components would oxidize and burn away (ash). The tube furnace’s atmosphere control ensures the material undergoes carbonization instead, preserving the carbon matrix.

Impact on Material Properties

Forming the Biochar Structure

By facilitating carbonization rather than combustion, the furnace converts the EPS into a stable, biochar-like structure. This acts as the physical backbone of the adsorbent.

Immobilizing Lanthanum Ions

The thermal process anchors the lanthanum ions within the carbonized matrix. The stability of this immobilization is directly dependent on the uniform heat distribution provided by the tube furnace.

Determining Pore Evolution

The precise temperature control dictates exactly how the pores within the material form and expand. The furnace ensures the temperature remains stable enough to develop surface functional groups without destroying them through overheating.

Understanding the Trade-offs

Atmosphere Sensitivity

While tube furnaces allow for atmosphere control, the system is intolerant to leaks. Even a minor introduction of oxygen during the 450°C phase can compromise the carbonization process and degrade the porous matrix.

Thermal Uniformity vs. Sample Volume

Tube furnaces provide excellent radial heating, but axial temperature gradients can exist at the ends of the tube. To ensure the La-EPS-C-450 is uniform, the sample must be placed strictly within the central "hot zone" of the furnace.

Optimization for Adsorbent Synthesis

To achieve the best results with La-EPS-C-450 synthesis, consider these focus areas:

- If your primary focus is Structural Stability: Ensure the nitrogen flow is established well before heating begins to completely purge oxygen and prevent early-stage oxidation.

- If your primary focus is Pore Distribution: Verify the furnace's ramp rate accuracy, as the speed of heating to 450°C affects how volatiles escape and pores form.

The precision of your thermal equipment directly correlates to the chemical stability and adsorption capacity of the final material.

Summary Table:

| Process Feature | Role in La-EPS-C-450 Modification | Critical Benefit |

|---|---|---|

| Nitrogen Atmosphere | Prevents oxidation and combustion of organic EPS | Preserves the carbon matrix structure |

| 450°C Calcination | Facilitates programmed carbonization | Converts biological material to biochar |

| Thermal Ramping | Controls the evolution of volatile gases | Ensures optimal pore structure and surface area |

| Ion Immobilization | Provides uniform heat for chemical anchoring | Stabilizes lanthanum ions within the matrix |

Elevate Your Adsorbent Synthesis with KINTEK Precision

Achieving the perfect carbonized matrix for materials like La-EPS-C-450 requires uncompromising thermal and atmosphere control. KINTEK provides industry-leading Tube, Muffle, Rotary, and Vacuum furnaces designed to meet the rigorous demands of advanced R&D.

Our systems offer the precise heating ramps and high-purity inert environments essential for preventing combustion and optimizing pore evolution. Whether you need a standard setup or a customized high-temp solution, our expert manufacturing ensures your lab achieves repeatable, high-performance results.

Ready to optimize your carbonization process? Contact KINTEK today to discuss your unique project requirements with our specialist team.

Visual Guide

References

- Yaoyao Lu, Ren‐Cun Jin. Lanthanum and Sludge Extracellular Polymeric Substances Coprecipitation-Modified Ceramic for Treating Low Phosphorus-Bearing Wastewater. DOI: 10.3390/w17081237

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- How does a tube furnace contribute to the synthesis of electrocatalysts from hydrochar? Precision Thermal Engineering

- How does the design and heating method of a tubular reactor facilitate simulated ethane cracking experiments?

- How does a tube vacuum furnace ensure quality during the solution treatment of aluminum matrix composites? Unlock Precision and Purity for Superior Materials

- What applications is a Split Tube Furnace (Single Zone) suitable for? Ideal for Uniform Heating and Easy Access

- What types of heating elements can be used in split tube furnaces? Choose SiC or MoSi2 for Optimal Performance

- What is a tubular furnace used for? A Guide to Precise High-Temperature Processing

- How does a high vacuum tube furnace ensure accuracy in Sn-Ag-Cu-Mn-Er solder experiments? Optimize Wetting Analysis

- What critical role does a laboratory tube furnace play in pBN-CTF synthesis? Master Molecular Engineering