In essence, a single-zone split tube furnace is a specialized tool for any laboratory process that demands a highly uniform temperature environment and easy access to the sample. It is perfectly suited for applications like material synthesis, annealing, and general thermal testing where the entire sample needs to be held at one consistent temperature.

Choosing the right furnace isn't about finding the "best" one, but the one that matches your specific thermal processing needs. A single-zone split tube furnace excels at providing simple, uniform heat and excellent sample accessibility, making it a workhorse for a specific class of experiments.

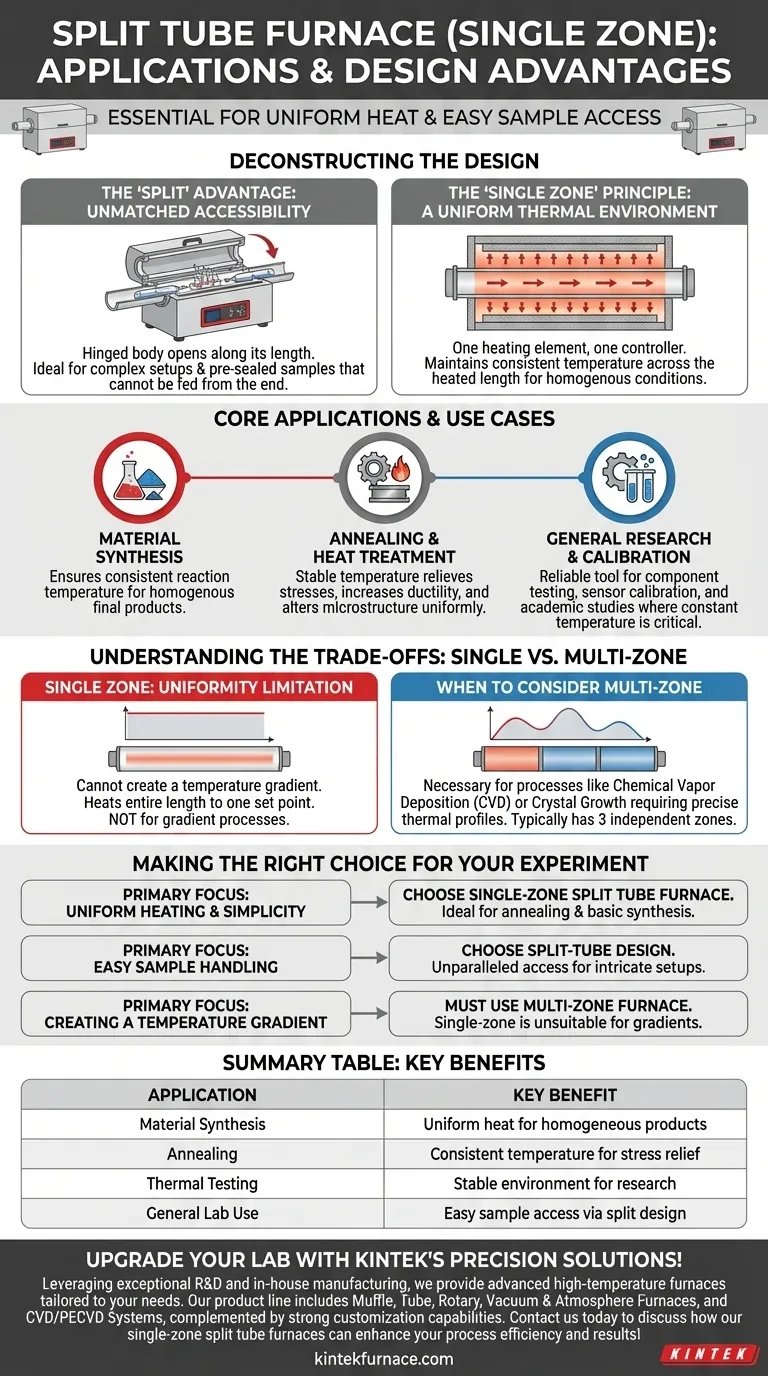

Deconstructing the Design: "Split" and "Single Zone"

To understand its applications, you must first understand its name. The design of the furnace directly dictates its function and suitability for a given task.

The "Split" Advantage: Unmatched Accessibility

The term "split" refers to the furnace's hinged body, which can be opened along its length.

This design provides a significant practical advantage: it allows operators to place or remove the entire work tube easily. This is invaluable when working with pre-sealed ampoules or complex experimental setups that cannot be fed through the end of a solid furnace.

The "Single Zone" Principle: A Uniform Thermal Environment

A "single zone" furnace has one heating element and one controller that maintains a consistent temperature across the entire heated length of the tube.

The goal of this design is to create a homogenous thermal environment. Any sample placed within the central hot zone will be subjected to the same temperature, which is critical for ensuring process consistency and material uniformity.

Core Applications and Use Cases

The combination of uniform heating and easy access makes the single-zone split tube furnace ideal for several key applications.

Material Synthesis

When creating new materials, powders, or compounds, a consistent reaction temperature is often paramount.

The furnace's uniform heat profile ensures that all parts of the precursor material react under the same conditions, leading to a more homogenous final product.

Annealing and Heat Treatment

Annealing is a process used to reduce hardness, increase ductility, and relieve internal stresses in materials by heating them to a specific temperature and then slowly cooling them.

A single-zone furnace provides the stable, consistent temperature required to effectively alter the material's microstructure without introducing new thermal stresses from temperature variations.

General Research and Calibration

This furnace acts as a reliable and versatile tool for a wide range of academic and industrial research.

It is used for component testing, sensor calibration, and fundamental studies where temperature is the primary independent variable and must be held constant.

Understanding the Trade-offs: Single vs. Multi-Zone

The primary strength of a single-zone furnace—its uniformity—is also its primary limitation. Knowing when it is not the right tool is just as important.

The Limitation of Uniformity

A single-zone furnace cannot create a temperature gradient. By design, it heats everything to one set point.

If your process requires one end of the sample to be hotter than the other, this furnace architecture is unsuitable.

When to Consider a Multi-Zone Furnace

Processes like Chemical Vapor Deposition (CVD) or certain types of crystal growth explicitly require a temperature gradient to drive the reaction.

For these applications, a multi-zone furnace (typically with three zones) is necessary. It has independent controllers for different sections of the tube, allowing you to create a precise thermal profile along its length.

Making the Right Choice for Your Experiment

Your experimental goal dictates the right equipment choice.

- If your primary focus is uniform heating and process simplicity: A single-zone split tube furnace is your ideal tool for its consistency and ease of use in applications like annealing or basic synthesis.

- If your primary focus is easy sample handling: The split-tube design provides unparalleled access for sealed tubes or intricate setups that cannot be easily inserted into a solid furnace.

- If your primary focus is creating a temperature gradient: You must use a multi-zone furnace, as a single-zone model is fundamentally not designed for this task.

Ultimately, selecting a single-zone split tube furnace is a deliberate choice for process control centered on thermal uniformity.

Summary Table:

| Application | Key Benefit |

|---|---|

| Material Synthesis | Uniform heat for homogeneous products |

| Annealing | Consistent temperature for stress relief |

| Thermal Testing | Stable environment for research |

| General Lab Use | Easy sample access via split design |

Upgrade your lab with KINTEK's precision solutions! Leveraging exceptional R&D and in-house manufacturing, we provide advanced high-temperature furnaces tailored to your needs. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet unique experimental requirements. If you're working on material synthesis, annealing, or thermal testing and need reliable, uniform heating with easy sample access, contact us today to discuss how our single-zone split tube furnaces can enhance your process efficiency and results!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- How do vertical tube furnaces comply with environmental standards? A Guide to Clean, Efficient Operation

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety