A tube vacuum furnace ensures quality primarily by creating a pristine, controlled environment that neutralizes the high reactivity of aluminum. By evacuating oxygen or backfilling with inert gases like argon, the furnace prevents the formation of oxide layers that degrade material properties, while simultaneously delivering the precise thermal uniformity required to dissolve strengthening phases without melting the composite matrix.

Success in treating aluminum matrix composites relies on managing the material's high affinity for oxygen and its narrow thermal processing window. A tube vacuum furnace solves both by eliminating atmospheric reactivity and providing the exacting temperature stability needed to lock in mechanical properties.

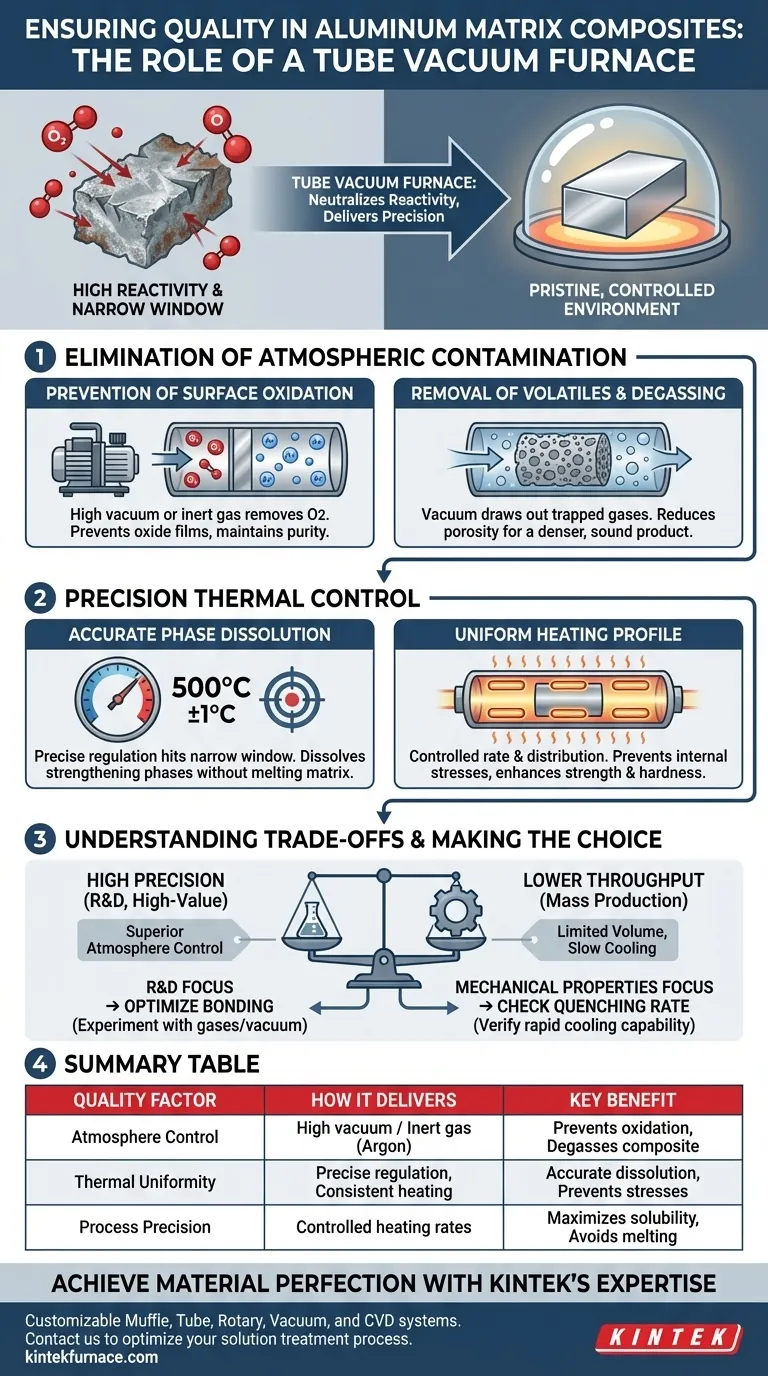

Elimination of Atmospheric Contamination

Prevention of Surface Oxidation

Aluminum has an extremely high affinity for oxygen, forming oxide films almost instantly when exposed to air at elevated temperatures.

A tube vacuum furnace mitigates this by operating in a high vacuum or an inert gas environment (such as argon). This oxygen-free setting ensures the aluminum matrix retains its purity and allows for optimal interaction with the reinforcement material.

Removal of Volatiles and Degassing

Composite materials often contain trapped gases or volatile impurities within the matrix or adsorbed onto the reinforcement particles.

The vacuum environment effectively draws these gases out of the material's interstitial spaces during the heating cycle. This "degassing" process significantly reduces porosity defects, leading to a denser, more structurally sound final product.

Precision Thermal Control

Accurate Phase Dissolution

Solution treatment requires heating the alloy to a specific temperature where strengthening phases dissolve into the aluminum matrix.

The margin for error is slim; overheating can melt low-melting-point eutectic phases, permanently damaging the composite. Tube furnaces provide the precise temperature regulation needed to hit this target window accurately, ensuring maximum solubility without structural degradation.

Uniform Heating Profile

Aluminum matrix composites can suffer from internal stresses if heated unevenly, especially given the different thermal expansion rates of the matrix and the reinforcement.

Tube furnaces allow for a highly controlled heating rate and uniform temperature distribution. This consistency results in a homogeneous material structure, which directly translates to stable mechanical properties like enhanced hardness and strength.

Understanding the Trade-offs

Quenching Limitations

Solution treatment is only effective if the material is cooled rapidly (quenched) to trap the dissolved phases.

Standard tube vacuum furnaces often rely on slow cooling or gas cooling, which may not be fast enough for certain aluminum alloys requiring an immediate water or oil quench. You must ensure the furnace is equipped with a rapid gas cooling system or has a mechanism to move the sample to a quench zone quickly.

Throughput vs. Precision

These furnaces are typically designed for high precision rather than high volume.

While they offer superior atmospheric control for high-value or R&D parts, the usable volume inside the tube is limited. This makes them less suitable for mass production of large components compared to larger batch vacuum furnaces.

Making the Right Choice for Your Goal

To maximize the utility of a tube vacuum furnace for your specific application, consider these strategic priorities:

- If your primary focus is Research and Development: Utilize the furnace's precise atmosphere control to experiment with different inert gases and vacuum levels to optimize interfacial bonding.

- If your primary focus is Mechanical Property Maximization: Verify that the furnace's cooling rate capabilities match the critical quenching speed required by your specific aluminum alloy grade.

By leveraging the precise environmental isolation of a tube vacuum furnace, you transform the solution treatment process from a risk of oxidation into an opportunity for material perfection.

Summary Table:

| Quality Assurance Factor | How a Tube Vacuum Furnace Delivers | Key Benefit |

|---|---|---|

| Atmosphere Control | Creates a high vacuum or inert gas (argon) environment. | Prevents surface oxidation and degasses the composite. |

| Thermal Uniformity | Provides precise temperature regulation and a consistent heating profile. | Ensures accurate phase dissolution and prevents internal stresses. |

| Process Precision | Allows for controlled heating rates to target a narrow thermal window. | Maximizes solubility of strengthening phases without melting the matrix. |

Achieve Material Perfection with KINTEK's Expertise

Ready to eliminate oxidation and unlock the full mechanical potential of your aluminum matrix composites? The precise control of a tube vacuum furnace is key.

At KINTEK, we specialize in designing and manufacturing high-performance laboratory furnaces. Backed by expert R&D and manufacturing, we offer Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable for your unique research and production needs.

Let our solutions provide the pristine environment and exacting thermal stability your materials require. Contact us today to discuss how we can optimize your solution treatment process.

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What is the significance of a rapid quenching device at the bottom of a lab tube furnace? Capture High-Temp Snapshot

- Why is a high-purity quartz tube used as the core reactor component in controlled combustion? Thermal and Optical Needs

- How does a three-tube diffusion furnace ensure the quality of thermal oxidation layers? Achieve High-Efficiency Passivation

- What are the key advantages of a tube furnace's design? Achieve Precise, Uniform Heating for Your Lab

- Why is a tube furnace with programmable temperature control necessary for graphene? Ensure High-Quality Graphene on Silver

- What is the necessity of using a Tube Furnace for phosphorus-doped carbon nanofiber films? Ensure Anaerobic Precision

- How do tube furnaces work? Achieve Precise Thermal Processing for Your Materials

- What is a quartz tube furnace and what is its primary use? Essential for Controlled High-Temp Processing