High-purity quartz is the material of choice for controlled combustion because it bridges the gap between thermal durability and optical accessibility. It is specifically engineered to withstand operating temperatures exceeding 700°C while maintaining total chemical inertness. Simultaneously, its transparency provides a clear window for advanced imaging equipment to capture critical data on flame mechanics.

Core Takeaway In combustion research, the reactor vessel must never become a variable in the experiment. High-purity quartz provides the necessary thermal stability to contain the reaction and the optical clarity required to measure it, without contaminating the environment with volatile impurities.

Ensuring Experimental Integrity

Withstanding Extreme Thermal Loads

Combustion environments generate intense heat that causes standard materials to degrade or fail.

High-purity quartz is utilized specifically for its exceptional high-temperature resistance. It allows the reactor to operate reliably at temperatures exceeding 700°C, maintaining structural integrity where other glasses might soften or shatter.

Maintaining Chemical Inertness

Temperature resistance alone is not enough; the material must also remain chemically neutral.

At high heat, lower-grade materials often release volatile impurities (outgassing). High-purity quartz remains chemically inert, ensuring that no foreign substances are introduced into the combustion environment to skew the chemical analysis.

The Critical Role of Transparency

Unobstructed Visualization

For researchers, seeing the reaction is just as important as containing it.

The inherent transparency of quartz allows for real-time observation of the combustion process. This optical access is necessary for tracking the evolution of the fire and understanding how the fuel reacts inside the core component.

Enabling High-Speed Diagnostics

Modern combustion analysis relies heavily on external instrumentation rather than just the naked eye.

The clear walls of the quartz tube permit the use of external high-speed cameras. These devices capture rapid flame propagation and spread mechanisms that would be impossible to analyze through opaque metal or ceramic reactors.

Understanding the Risks of Material Selection

The Pitfall of Impurities

The primary trade-off in selecting a reactor material is often between cost and purity.

Using quartz that is not "high-purity" poses a significant risk to data validity. Even minor impurities can volatilize at 700°C, introducing unknown variables into the flame chemistry and rendering the study of fire spread mechanisms inaccurate.

Making the Right Choice for Your Goal

If you are designing a controlled combustion environment, align your material choice with your specific data requirements:

- If your primary focus is Chemical Analysis: Prioritize high-purity grades to ensure zero release of volatile impurities at operating temperatures.

- If your primary focus is Flame Dynamics: Ensure the tube offers high optical transmission to facilitate unobstructed recording by high-speed cameras.

High-purity quartz remains the only material that successfully delivers both the thermal resilience required for safety and the optical clarity required for insight.

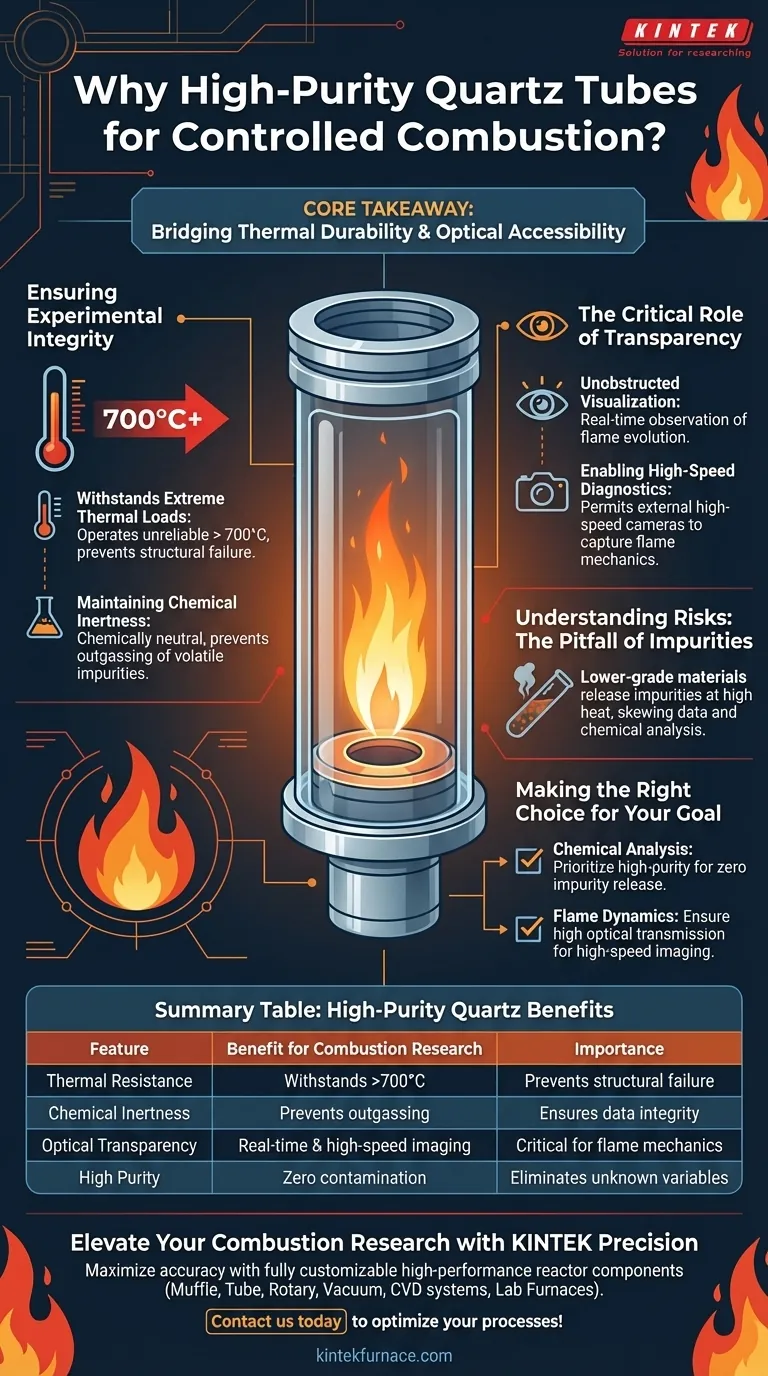

Summary Table:

| Feature | Benefit for Combustion Research | Importance |

|---|---|---|

| Thermal Resistance | Withstands temperatures exceeding 700°C | Prevents structural failure/shattering |

| Chemical Inertness | Prevents outgassing of volatile impurities | Ensures experimental data integrity |

| Optical Transparency | Allows real-time visualization & high-speed imaging | Critical for tracking flame mechanics |

| High Purity | Zero contamination of the reaction environment | Eliminates unknown chemical variables |

Elevate Your Combustion Research with KINTEK Precision

Maximize your experimental accuracy with high-performance reactor components. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, alongside specialized lab high-temp furnaces—all fully customizable to your unique thermal and optical requirements.

Don't let material impurities compromise your data. Contact us today to discover how our high-purity solutions can optimize your high-temperature laboratory processes!

Visual Guide

References

- Casey Coffland, Elliott T. Gall. An open-source linear actuated-quartz tube furnace with programmable ceramic heater movement for laboratory-scale studies of combustion and emission. DOI: 10.2139/ssrn.5687995

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

People Also Ask

- Why is a high-temperature tube furnace required for LNMO synthesis? Achieve Precise Fd-3m Spinel Structures

- Why is a precision tube furnace required for Nitrogen-doped SiOC synthesis? Ensure Perfect Structural Integrity

- Why are high-temperature tube furnaces used for TiZrMoSn0.8Hf0.2 alloys? Essential Benefits for Material Science

- What are the steps involved in calibrating the temperature control system of a tube furnace? Ensure Precision and Repeatability

- What is the key component of a tube furnace and how is it constructed? Unlock Precision Heating for Your Lab

- How does a high-precision tube furnace facilitate the one-step carbonization of molybdenum carbide catalysts?

- What function does a tube furnace serve in converting electrospun fibers into CNFs? Mastering the Carbonization Path

- Why is a tube furnace with programmable temperature control necessary for graphene? Ensure High-Quality Graphene on Silver