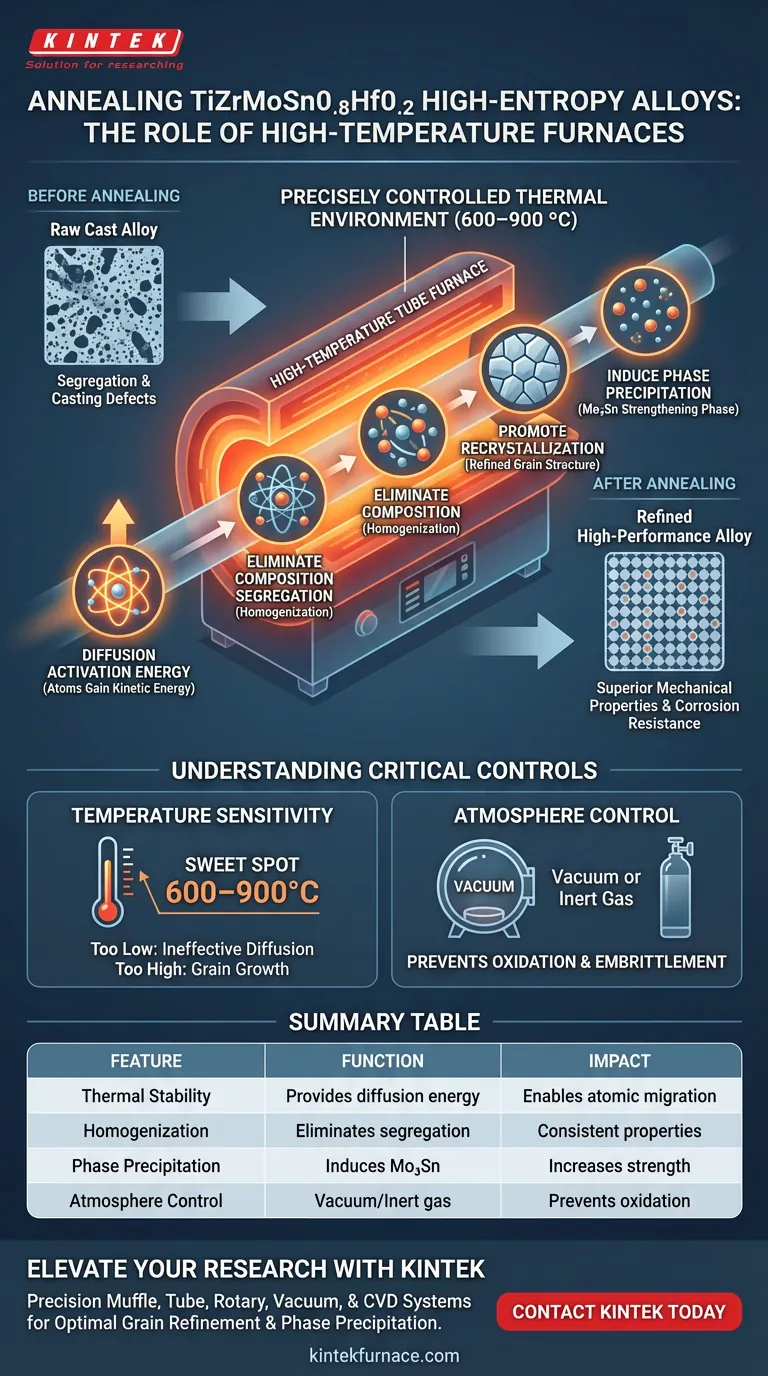

High-temperature tube furnaces or resistance furnaces are utilized to create a precisely controlled thermal environment necessary for annealing TiZrMoSn0.8Hf0.2 high-entropy alloys. By maintaining a constant temperature, typically between 600 and 900 °C, these furnaces provide the thermal stability required to alter the atomic structure of the material, enabling critical diffusion processes that are impossible at room temperature.

Core Takeaway The annealing process in these furnaces is not merely about heating; it is a mechanism to provide atoms with diffusion activation energy. This energy drives the elimination of casting defects, refines the grain structure, and triggers the precipitation of specific strengthening phases like Mo3Sn, which are essential for the alloy's superior mechanical properties and corrosion resistance.

The Role of Thermal Energy in Microstructural Evolution

Providing Diffusion Activation Energy

The primary function of the furnace is to supply diffusion activation energy. At temperatures between 600 and 900 °C, the atoms within the TiZrMoSn0.8Hf0.2 alloy gain enough kinetic energy to migrate through the crystal lattice. Without this controlled high-temperature exposure, the atoms would remain locked in their original positions, preventing any beneficial structural changes.

Eliminating Composition Segregation

Cast alloys often suffer from composition segregation, where elements are distributed unevenly during the initial solidification. The tube furnace maintains a stable thermal field that allows elements to diffuse from areas of high concentration to low concentration. This homogenizes the material, eliminating dendritic segregation and ensuring consistent properties throughout the alloy.

Promoting Recrystallization

The thermal energy provided by the furnace induces recrystallization. This process replaces deformed or irregular grains with a new set of defect-free grains. This refinement of the microstructure is critical for relieving internal stresses introduced during casting or prior processing.

Enhancing Material Performance Through Precipitation

Inducing Phase Precipitation

A critical outcome of this specific annealing process is the precipitation of strengthening phases, particularly Mo3Sn. The furnace environment allows the alloy to reach a thermodynamic state where these beneficial second phases can form. These precipitates act as obstacles to dislocation movement, which directly strengthens the material.

Improving Mechanical and Corrosion Properties

The combination of microstructural refinement and phase precipitation significantly enhances the alloy's performance. The presence of Mo3Sn and a homogenized structure leads to higher mechanical strength. Simultaneously, the elimination of segregation improves the alloy's resistance to corrosion, making it suitable for harsh environments.

Understanding the Trade-offs

Temperature Sensitivity

Precise control is non-negotiable; if the temperature is too low (below 600 °C), the atoms will lack the energy to diffuse, rendering the anneal ineffective. Conversely, excessive temperatures (significantly above 900 °C) can lead to unwanted grain growth, which may reduce the material's strength. The tube furnace is specifically chosen for its ability to maintain the "sweet spot" required for this specific alloy composition.

Atmosphere Control and Oxidation Risks

While the primary reference focuses on temperature, supplementary context indicates that high-entropy alloys containing Titanium, Zirconium, and Hafnium are highly reactive to oxygen. High-temperature tube furnaces are typically designed to operate under vacuum or inert gas atmospheres. Failing to control the atmosphere inside the furnace can lead to the formation of brittle oxide or nitride layers, which would compromise the mechanical data and embrittle the material.

Making the Right Choice for Your Goal

When annealing TiZrMoSn0.8Hf0.2 high-entropy alloys, your specific objectives should dictate your process parameters:

- If your primary focus is Strength: Ensure the temperature is maintained within the 600–900 °C range to maximize the precipitation of the Mo3Sn strengthening phase.

- If your primary focus is Homogeneity: Prioritize longer dwell times at stable temperatures to allow for complete atomic diffusion and the elimination of casting segregation.

- If your primary focus is Data Accuracy: utilize a controlled atmosphere (vacuum/inert gas) within the furnace to prevent surface oxidation from skewing your assessment of the material's inherent properties.

The precise application of thermal energy converts a raw, segregated casting into a refined, high-performance engineering material.

Summary Table:

| Feature | Function in Annealing | Impact on Alloy Performance |

|---|---|---|

| Thermal Stability | Provides diffusion activation energy (600-900 °C) | Enables atomic migration and microstructural evolution |

| Homogenization | Eliminates composition segregation | Removes dendritic defects for consistent material properties |

| Phase Precipitation | Induces Mo3Sn strengthening phases | Significantly increases mechanical strength and hardness |

| Atmosphere Control | Vacuum or inert gas environment | Prevents oxidation and embrittlement of reactive elements |

Elevate Your Material Research with KINTEK

Precision is paramount when processing complex high-entropy alloys like TiZrMoSn0.8Hf0.2. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, along with other specialized lab high-temp furnaces. Our solutions are fully customizable to meet your unique thermal processing needs, ensuring optimal grain refinement and phase precipitation for your research.

Ready to achieve superior material properties? Contact KINTEK today to find the perfect furnace solution for your laboratory.

Visual Guide

References

- Yanfei Xu, Guangsheng Zeng. Effect of annealing treatment on microstructure, wear resistance and corrosion properties of TiZrMoSn0.8Hf0.2 high-entropy alloy for biomedical applications. DOI: 10.1088/2053-1591/ae0fdd

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

People Also Ask

- What are the key components of a tube furnace's heating mechanism? Discover Precision Heating for Your Lab

- What is the role of integrated CO2 sensors in a tube furnace? Enhance Combustion Emission Analysis and Accuracy

- What is the role of a Tube Furnace or Rotary Furnace in hydrogen reduction roasting? Optimize Lithium Recovery Efficiency.

- How does gas flow control in a tube furnace influence the quality of NMC811? Master Stable Calcination Environments

- What role does a tube furnace play in Se/NC composite synthesis? Mastering the Melt-Diffusion Method

- What role does an atmosphere tube furnace play in the thermal cyclization of PAN? Unlock High-Performance Electrodes

- What is the purpose of using high-purity quartz tubes and vacuum sealing for Cu13Se52Bi35 alloy preparation?

- What is the three-step heating process in graphite furnace atomization? Master Precise Trace Metal Analysis