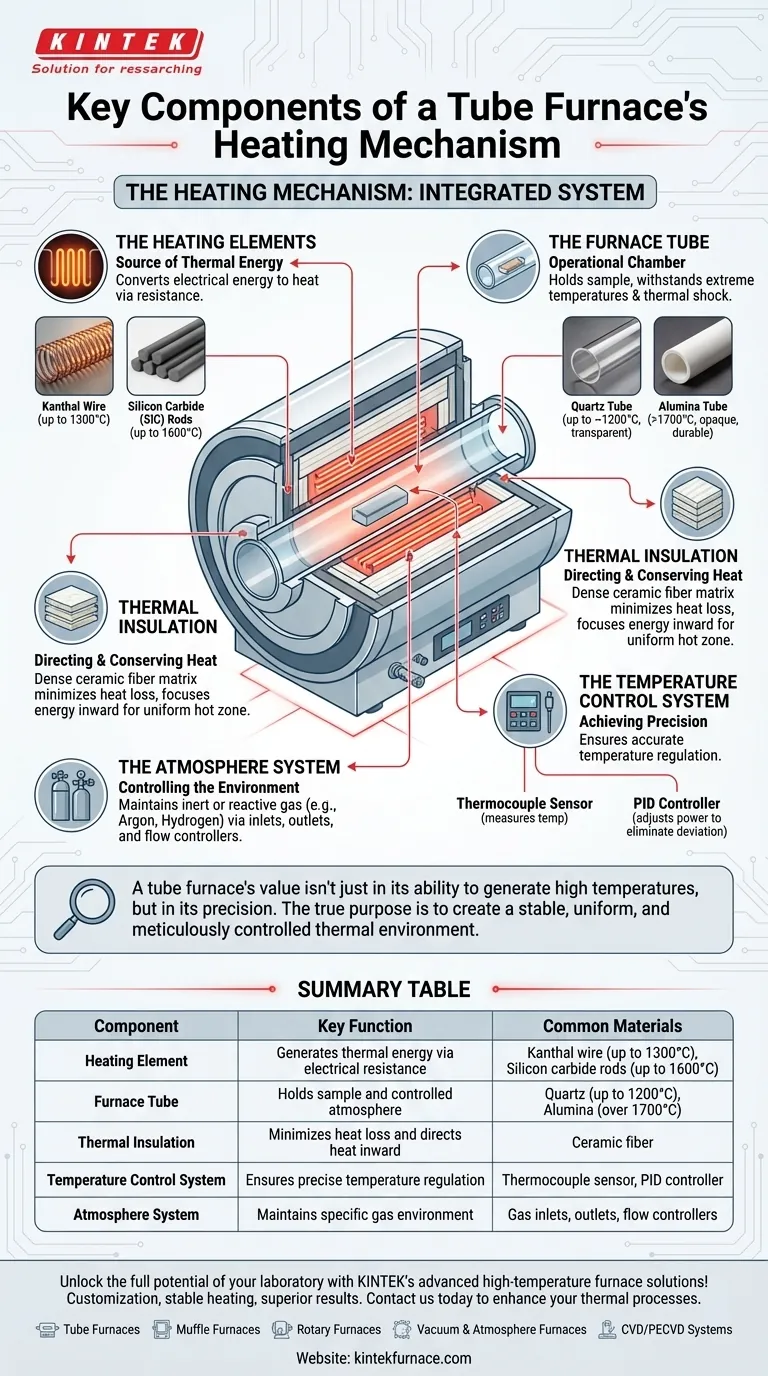

The heating mechanism of a tube furnace is an integrated system built from four primary components: the heating elements that generate thermal energy, the furnace tube that contains the sample, the thermal insulation that directs the heat, and the temperature control system that ensures precision. These parts work in concert to convert electrical energy into a stable and uniform high-temperature environment.

A tube furnace's value isn't just in its ability to generate high temperatures, but in its precision. The true purpose of its heating mechanism is to create a stable, uniform, and meticulously controlled thermal environment within the furnace tube.

The Core Components of Thermal Generation

The fundamental goal is to generate and contain heat efficiently. This is accomplished by a carefully selected set of materials designed for high-temperature performance.

The Heating Element: The Source of Thermal Energy

The heart of the furnace is the heating element, which works on the principle of electrical resistance. An electric current is passed through a material with high resistance, converting electrical energy directly into heat.

The material choice for these elements is critical and depends on the target temperature range. The two most common types are Kanthal (FeCrAl alloy) wire and silicon carbide (SiC) rods.

The Furnace Tube: The Operational Chamber

The furnace tube is the central chamber that holds the sample and, if needed, a controlled atmosphere. It is positioned inside the heating elements.

These tubes must be resistant to extreme temperatures and thermal shock. Common materials include quartz, which is suitable for temperatures up to ~1200°C, and alumina, a ceramic that can withstand much higher temperatures, often exceeding 1700°C.

Thermal Insulation: Directing and Conserving Heat

Surrounding the heating elements is a dense thermal insulation matrix, typically made of high-purity ceramic fiber.

This insulation serves two critical functions. First, it minimizes heat loss to the surrounding environment, drastically improving energy efficiency. Second, it directs the thermal energy inward, focusing it on the furnace tube to create a uniform hot zone.

The Brains of the Operation: Achieving Precision

Generating heat is simple; controlling it with high accuracy is the real engineering challenge. This is where the control systems become indispensable.

The Temperature Control System: Ensuring Accuracy

This system acts as the furnace's brain, ensuring the temperature inside the tube is exactly what you set. It consists of a sensor, typically a thermocouple, placed near the furnace tube.

The thermocouple constantly measures the temperature and sends this data to a PID controller (Proportional-Integral-Derivative). The controller compares the actual temperature to the desired setpoint and precisely adjusts the power sent to the heating elements to eliminate any deviation.

The Atmosphere System: Controlling the Environment

While not a direct heating component, the atmosphere control system is integral to the overall thermal process. Many applications require processing a sample in an inert (e.g., Argon) or reactive (e.g., Hydrogen) gas environment.

This system, which includes gas inlets, outlets, and flow controllers, works with the sealed furnace tube to maintain a specific chemical environment at high temperatures.

Understanding the Trade-offs: Material Selection Matters

The choice of components dictates the furnace's capabilities, limitations, and cost. Understanding these trade-offs is key to selecting the right tool for the job.

Heating Element: Kanthal vs. Silicon Carbide

Kanthal wire is cost-effective and reliable for applications up to approximately 1300°C. It is the standard for most general-purpose laboratory furnaces.

Silicon carbide (SiC) rods are required for higher temperatures, typically from 1400°C to 1600°C. They are more expensive and can become brittle over time but are essential for high-temperature ceramics and materials research.

Furnace Tube: Quartz vs. Alumina

A quartz tube offers the significant advantage of being transparent at lower temperatures, allowing for visual observation of the process. However, it has a lower maximum operating temperature and can be more susceptible to thermal shock.

An alumina tube is opaque but far more durable and capable of handling extremely high temperatures. It is the default choice for high-temperature processing, sintering, and annealing where visual access is not required.

Making the Right Choice for Your Application

Selecting a furnace configuration depends entirely on your specific experimental or production goals.

- If your primary focus is high-temperature processing (>1400°C): You will require a system with silicon carbide heating elements and a high-purity alumina tube.

- If your primary focus is visual observation or lower-temperature work (<1200°C): A furnace with Kanthal wire elements and a quartz tube is the most practical and cost-effective choice.

- If your primary focus is precise atmospheric control: Ensure the furnace features robust end seals and a reliable gas flow control system, as this is as critical as the heating components.

Ultimately, understanding how these components work together empowers you to select or operate a furnace that delivers the precise thermal environment your work demands.

Summary Table:

| Component | Key Function | Common Materials |

|---|---|---|

| Heating Element | Generates thermal energy via electrical resistance | Kanthal wire (up to 1300°C), Silicon carbide rods (up to 1600°C) |

| Furnace Tube | Holds sample and controlled atmosphere | Quartz (up to 1200°C), Alumina (over 1700°C) |

| Thermal Insulation | Minimizes heat loss and directs heat inward | Ceramic fiber |

| Temperature Control System | Ensures precise temperature regulation | Thermocouple sensor, PID controller |

| Atmosphere System | Maintains specific gas environment | Gas inlets, outlets, flow controllers |

Unlock the full potential of your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with reliable equipment like Tube Furnaces, Muffle Furnaces, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements, delivering stable, uniform heating for superior results. Contact us today to discuss how we can enhance your thermal processes and drive innovation in your work!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab