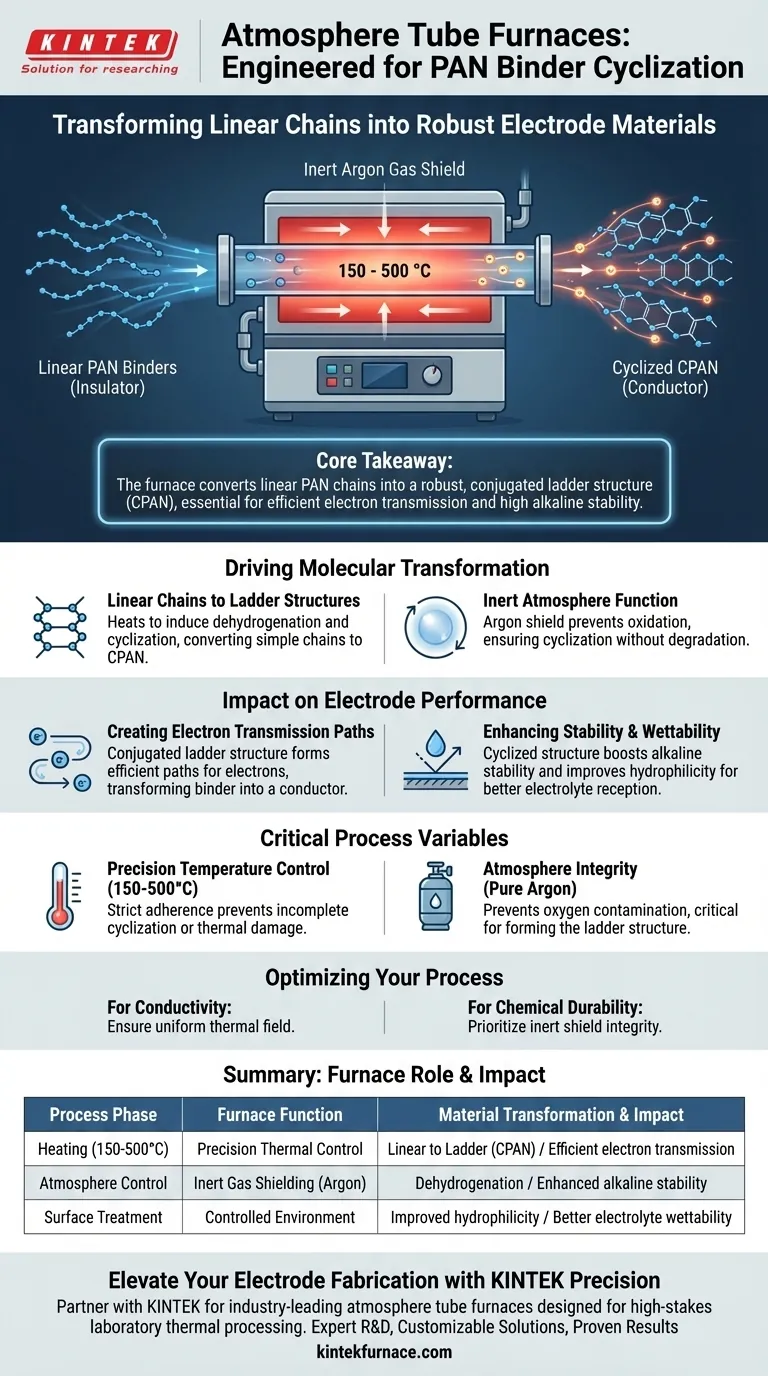

The atmosphere tube furnace serves as the precision reaction chamber required to chemically transform polyacrylonitrile (PAN) binders into functional electrode materials. It maintains a strictly controlled temperature range of 150 to 500 °C while enveloping the material in an inert gas shield, typically argon, to facilitate dehydrogenation and cyclization without oxidation.

Core Takeaway The furnace drives the conversion of PAN molecular chains from a simple linear structure into a robust, conjugated ladder structure (CPAN). This transformation is the fundamental requirement for creating electrodes with efficient electron transmission paths and high alkaline stability.

Driving the Molecular Transformation

From Linear Chains to Ladder Structures

The primary role of the furnace is to facilitate a radical change in the binder’s molecular architecture.

It heats the material to induce dehydrogenation and cyclization reactions.

This process converts the original linear polyacrylonitrile chains into cyclized polyacrylonitrile (CPAN), characterized by a conjugated ladder structure.

The Function of the Inert Atmosphere

Standard ovens cannot perform this task effectively because oxygen disrupts the chemical bonding process.

The "atmosphere" aspect of the tube furnace creates a stable, oxygen-free environment using an inert gas like argon.

This shield ensures that the heat treatment yields the desired cyclized structure rather than burning or degrading the polymer.

Impact on Electrode Performance

Creating Electron Transmission Paths

The structural change driven by the furnace is not merely physical; it is electrical.

The resulting conjugated ladder structure acts as a highway for electrons, forming efficient electron transmission paths.

Without the precise thermal history provided by the furnace, the binder would remain an insulator rather than a conductor.

Enhancing Stability and Wettability

The furnace processing directly dictates the mechanical and chemical resilience of the final electrode.

The cyclized structure significantly enhances alkaline stability, preventing the electrode from degrading in harsh chemical environments.

Furthermore, the treatment improves hydrophilicity, making the electrode surface more receptive to electrolytes.

Critical Process Variables

Precision Temperature Control

Success depends on maintaining a thermal field strictly between 150 and 500 °C.

Fluctuations outside this range can lead to incomplete cyclization or thermal damage to the polymer backbone.

Atmosphere Integrity

The quality of the outcome is directly tied to the purity of the inert gas environment.

Any breach in the argon shield allows oxygen to enter, compromising the formation of the conjugated ladder structure.

Optimizing Your Thermal Process

To ensure the highest quality electrode fabrication, align your furnace parameters with your specific performance targets:

- If your primary focus is Electrical Conductivity: Ensure your furnace creates a uniform thermal field to maximize the formation of electron transmission paths through the conjugated structure.

- If your primary focus is Chemical Durability: Prioritize the integrity of the inert gas shield to guarantee the formation of a fully cyclized, alkaline-stable material.

The atmosphere tube furnace is not just a heating element; it is the tool that engineers the molecular stability and conductivity of your electrode.

Summary Table:

| Process Phase | Furnace Function | Material Transformation | Impact on Electrode |

|---|---|---|---|

| Heating (150-500°C) | Precision Thermal Control | Linear chains to ladder structures (CPAN) | Efficient electron transmission paths |

| Atmosphere Control | Inert Gas Shielding (Argon) | Dehydrogenation without oxidation | Enhanced alkaline stability |

| Surface Treatment | Controlled Environment | Improved material hydrophilicity | Better electrolyte wettability |

Elevate Your Electrode Fabrication with KINTEK Precision

Don't let oxygen contamination or temperature fluctuations compromise your material research. KINTEK provides industry-leading atmosphere tube furnaces, vacuum systems, and CVD solutions designed specifically for high-stakes laboratory thermal processing.

Why partner with KINTEK?

- Expert R&D & Manufacturing: Our systems ensure the strictly controlled 150-500°C thermal fields and atmosphere integrity required for PAN cyclization.

- Customizable Solutions: Whether you need a rotary, muffle, or specialized tube furnace, we tailor every unit to your unique electrode performance targets.

- Proven Results: Create more stable, conductive, and durable materials with equipment built for precision.

Contact KINTEK Today for a Customizable Quote

Visual Guide

References

- Yifan Gu, Yi Feng. A Novel Cyclized Polyacrylonitrile Binder Strategy for Efficient Oxygen Evolution Reaction Catalysts. DOI: 10.3390/polym17182477

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What role does a high-temperature tube furnace play in the solid-state synthesis of LIB cathode materials? Key Insights

- What is the primary function of a high-temperature tube furnace in Bi-doped CaZnOS synthesis? Achieving Phase Purity

- What is the critical role of a tube furnace in the preparation of beta-PbO powder? Optimize Lead-Acid Battery Recycling

- What is a quartz tube furnace and what is its primary use? Essential for Controlled High-Temp Processing

- What is the significance of the gas path control system in a laboratory tube furnace during activated carbon synthesis?

- How are drop tube furnaces used in industrial settings? Boost Efficiency in Material Processing

- What are the key characteristics of a 70mm tube furnace? Unlock Precision Heating for Your Lab

- Why is thermal uniformity important in a drop tube furnace? Ensure Reliable Results and Consistent Processes