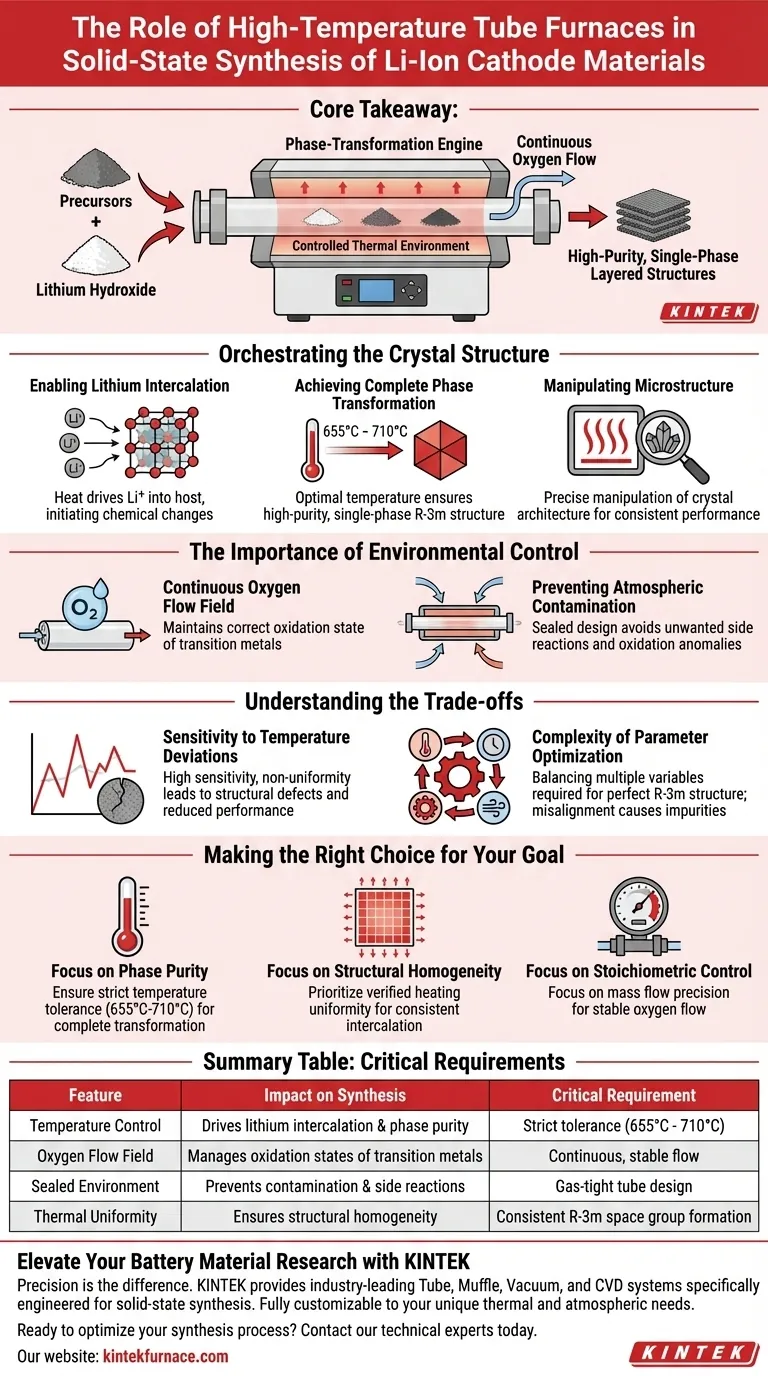

A high-temperature tube furnace serves as the critical reaction vessel for the solid-state synthesis of lithium-ion battery cathode materials. It provides a highly controlled thermal environment and a continuous oxygen flow field, which are essential for driving the reaction between precursors and lithium hydroxide powders. This precise environment facilitates the intercalation of lithium ions into the crystal lattice, ensuring the material achieves the necessary electrochemical properties.

Core Takeaway The tube furnace is not merely a heating element; it is a phase-transformation engine. By maintaining strict temperature profiles and continuous gas flow, it ensures the complete conversion of raw precursors into high-purity, single-phase layered structures required for high-performance batteries.

Orchestrating the Crystal Structure

Enabling Lithium Intercalation

The primary goal of the solid-state reaction is the successful intercalation of lithium ions.

The tube furnace facilitates this by heating the mixture of precursors and lithium hydroxide to a specific, optimized temperature range. This thermal energy drives the lithium into the host structure, initiating the chemical changes required for energy storage.

Achieving Complete Phase Transformation

Temperature control is the deciding factor in the purity of the final material.

Typically operating between 655°C and 710°C, the furnace ensures that the reaction proceeds to completion. This results in the formation of a high-purity, single-phase layered structure, specifically characterized by the R-3m space group.

Manipulating Microstructure

Beyond basic chemistry, the furnace dictates the physical architecture of the material.

The capacity for uniform heating allows researchers to precisely manipulate the material's crystal structure and microstructure. This uniformity is vital for ensuring that the cathode material performs consistently across the entire batch.

The Importance of Environmental Control

Continuous Oxygen Flow Field

Temperature alone is insufficient for this specific synthesis; the atmospheric condition is equally critical.

The tube furnace provides a continuous oxygen flow field throughout the heating process. This ensures that the oxidation state of the transition metals within the cathode material is correctly maintained during synthesis.

Preventing Atmospheric Contamination

While some processes require inert nitrogen environments (as seen in carbonization or selenization), cathode synthesis often relies on this controlled flow to manage reactions.

The tube furnace's sealed design allows for strict management of the gas environment. This prevents unwanted side reactions or oxidation anomalies that could degrade the electrochemical performance of the final product.

Understanding the Trade-offs

Sensitivity to Temperature Deviations

The specific window for optimal calcination (655°C to 710°C) implies a high sensitivity to thermal fluctuations.

If the furnace fails to maintain uniformity, parts of the batch may undergo incomplete phase transformation. This results in structural defects that significantly reduce the battery's capacity and cycle life.

Complexity of Parameter Optimization

Achieving the perfect R-3m structure requires balancing multiple variables simultaneously.

Operators must precisely correlate the temperature rise curves, isothermal soaking times, and gas flow rates. A misalignment in any of these parameters can lead to impurities or multiphase structures rather than the desired single-phase material.

Making the Right Choice for Your Goal

To maximize the effectiveness of your solid-state synthesis, align your furnace operation with your specific material targets.

- If your primary focus is Phase Purity: Ensure your furnace can hold a strict temperature tolerance within the 655°C to 710°C window to guarantee complete transformation to the R-3m space group.

- If your primary focus is Structural Homogeneity: Prioritize a furnace with verified heating uniformity to ensure consistent lithium intercalation across the entire sample volume.

- If your primary focus is Stoichiometric Control: Focus on the precision of the mass flow controllers to maintain a stable, continuous oxygen flow field throughout the reaction.

Success in cathode synthesis is defined by the precision of your thermal and atmospheric control.

Summary Table:

| Feature | Impact on Synthesis | Critical Requirement |

|---|---|---|

| Temperature Control | Drives lithium intercalation and phase purity | Strict tolerance (655°C - 710°C) |

| Oxygen Flow Field | Manages oxidation states of transition metals | Continuous, stable flow |

| Sealed Environment | Prevents contamination and side reactions | Gas-tight tube design |

| Thermal Uniformity | Ensures structural homogeneity across batch | Consistent R-3m space group formation |

Elevate Your Battery Material Research with KINTEK

Precision is the difference between a failing battery and a high-performance cell. KINTEK provides industry-leading Tube, Muffle, Vacuum, and CVD systems specifically engineered for the rigorous demands of solid-state synthesis.

Backed by expert R&D and world-class manufacturing, our high-temperature furnaces are fully customizable to your unique thermal profiles and atmospheric needs. Ensure your cathode materials achieve perfect phase purity and structural homogeneity every time.

Ready to optimize your synthesis process? Contact our technical experts today to find the perfect furnace solution for your laboratory.

Visual Guide

References

- Chen Liu, Arumugam Manthiram. Delineating the Triphasic Side Reaction Products in High‐Energy Density Lithium‐Ion Batteries. DOI: 10.1002/adma.202509889

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- Why are near alpha-titanium alloy ingots often sealed in quartz tubes? Unlock Superior Purity and Microstructure

- What role does a tube furnace play within a fixed-bed adsorption system? Expert Se/PPS Performance Evaluation Guide

- What are the technical advantages of using a horizontal tube furnace for the slow pyrolysis of cotton stalks?

- How does a vacuum tube furnace serve as the core equipment in the consolidation of Ti-xCr-2Ge alloys?

- What is the purpose of pre-treating sapphire substrates in a tube furnace? Optimize Your Epitaxial Growth Foundation

- What is the role of the tubular furnace annealing process in the synthesis of Si@SnO2? Achieve Precise Nanocoatings

- How is a high-temperature tube furnace utilized for biochar activation? Enhance Porosity with CO2 Etching

- What are the core functions of a tube sintering furnace in Fe3C/NC pyrolysis? Master Your Synthesis Process