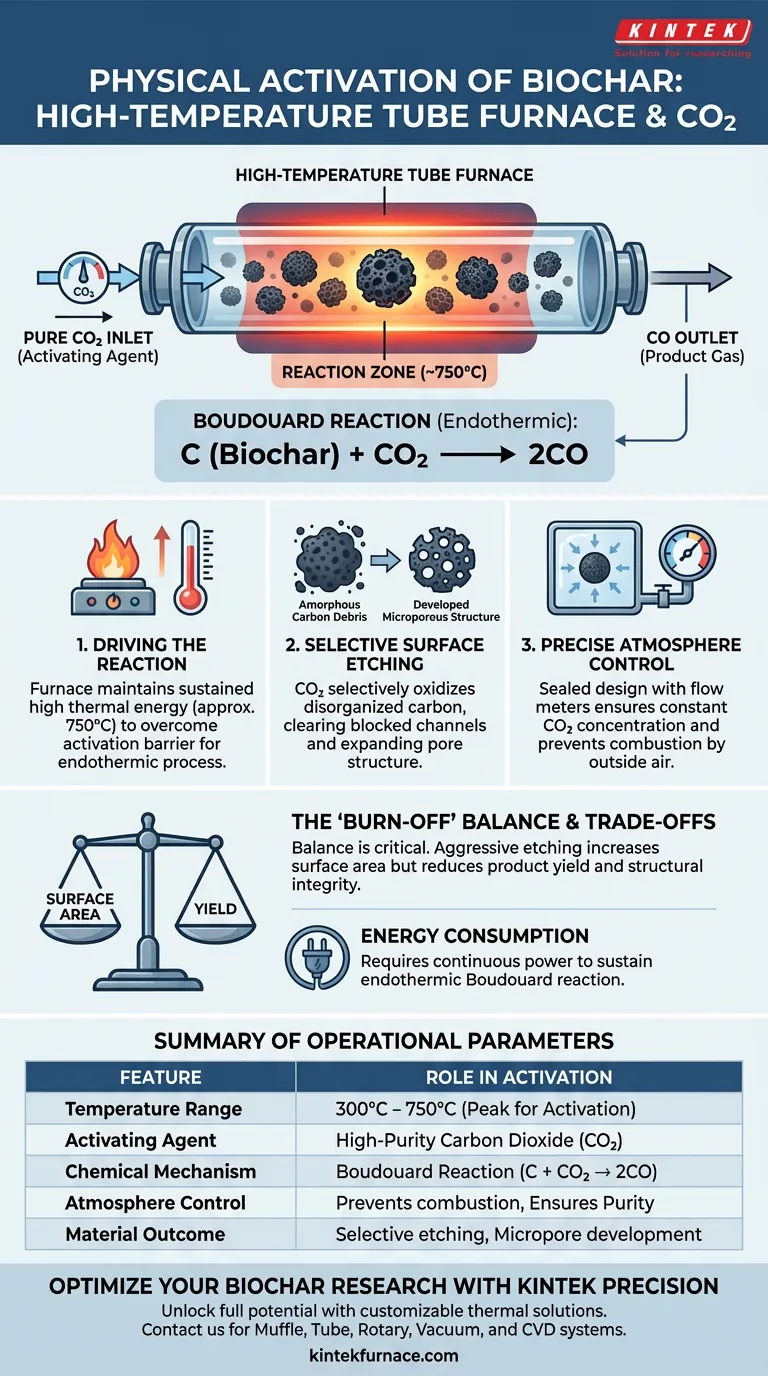

In the physical activation of biochar, a high-temperature tube furnace functions as a precise reaction vessel rather than a simple heating element. It facilitates a specific chemical interaction between the solid carbon structure and gaseous carbon dioxide at approximately 750 °C. This controlled environment allows the CO2 to selectively oxidize and "etch" the biochar surface, stripping away amorphous carbon to reveal and expand the material's internal pore structure.

The furnace acts as the engine for the Boudouard reaction (C + CO2 → 2CO), an endothermic process where carbon dioxide consumes specific carbon atoms. This selectively clears blocked channels and significantly increases the specific surface area, optimizing the biochar’s microporous structure.

The Mechanism of Physical Activation

Driving the Boudouard Reaction

The core function of the furnace during this phase is to drive the Boudouard reaction. This is a thermochemical process where carbon dioxide reacts with the solid carbon of the biochar to produce carbon monoxide.

Because this reaction is endothermic (absorbs heat), the furnace must maintain a consistent high temperature—typically around 750 °C—to ensure the reaction proceeds efficiently. Without this sustained thermal energy, the activation energy barrier cannot be overcome, and the CO2 would remain inert.

Selective Surface Etching

Inside the sealed tube, the CO2 acts as an activating agent. It does not burn the biochar indiscriminately; instead, it selectively targets and oxidizes the more reactive, disorganized amorphous carbon.

This "etching" process removes the debris that blocks the internal channels of the biochar. By clearing these blockages, the furnace operation effectively transforms a material with low porosity into one with a highly developed microporous structure.

Precise Atmosphere Control

The tube furnace’s sealed design is critical for maintaining a pure reaction environment. It allows for the introduction of high-purity carbon dioxide via flow meters, ensuring the concentration of the activating agent is constant.

This control prevents outside air from entering, which would lead to uncontrolled combustion (burning the biochar to ash) rather than controlled activation (developing pores).

Operational Parameters and Control

Temperature Regulation

Success depends on thermal stability. The furnace must hold the reaction zone at specific temperatures, often between 300 °C and 750 °C depending on the specific stage, though activation peaks near the upper end of this range.

Advanced tube furnaces allow for precise heating rates (e.g., 20 °C per minute). This gradual ramp-up prevents thermal shock and ensures the structural integrity of the carbon skeleton is maintained before the activation temperature is reached.

Pore Structure Development

The ultimate goal of the furnace operation is to modify the texture of the carbon. By controlling the duration and temperature of the CO2 exposure, the process expands rough pores formed during initial pyrolysis.

This results in a dramatic increase in specific surface area. The process can be tuned to develop specific pore sizes, primarily enhancing microporosity which is essential for applications like adsorption and electrochemical energy storage.

Understanding the Trade-offs

The "Burn-off" Balance

The most critical trade-off in using a tube furnace for CO2 activation is the balance between surface area and yield.

The activation process works by consuming carbon atoms. If the furnace temperature is set too high or the residence time is too long, the "etching" becomes too aggressive. While this might create massive surface area initially, it eventually collapses the pore walls and destroys the material, resulting in extremely low product yield and structural failure.

Energy Consumption

Maintaining a tube furnace at 750 °C+ for the duration required to facilitate the endothermic Boudouard reaction is energy-intensive. Unlike exothermic reactions that sustain themselves, this process requires continuous power input to drive the chemical changes.

Making the Right Choice for Your Goal

When configuring a tube furnace for biochar activation, your settings should be dictated by your specific end-use requirements.

- If your primary focus is Maximum Adsorption Capacity: Prioritize higher temperatures (around 750 °C) and longer hold times to maximize micropore development and surface area, accepting a lower total yield.

- If your primary focus is Structural Stability: Use a moderate temperature and shorter activation time to clear amorphous carbon while preserving the mechanical strength and bulk volume of the carbon skeleton.

Ultimately, the tube furnace is the instrument of compromise, balancing thermal energy and gas flow to carve functionality out of raw carbon.

Summary Table:

| Feature | Role in Biochar Activation |

|---|---|

| Temperature Range | Typically 300 °C to 750 °C to drive endothermic reactions |

| Activating Agent | High-purity Carbon Dioxide (CO2) |

| Chemical Mechanism | Boudouard Reaction (C + CO2 → 2CO) |

| Atmosphere Control | Precise flow meters and sealed tubes prevent combustion |

| Material Outcome | Selective etching of amorphous carbon to develop micropores |

Optimize Your Carbon Activation with KINTEK Precision

Unlock the full potential of your biochar research with KINTEK’s advanced thermal solutions. Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable to meet your unique laboratory needs.

Whether you are scaling up micropore development or perfecting selective surface etching, our high-temperature tube furnaces provide the thermal stability and atmosphere control essential for the Boudouard reaction.

Ready to elevate your material science? Contact our experts today to find your custom furnace solution.

Visual Guide

References

- Kinga Morlo, Ryszard Dobrowolski. Optimization of Pt(II) and Pt(IV) Adsorption from a Water Solution on Biochar Originating from Honeycomb Biomass. DOI: 10.3390/molecules29020547

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What role does a tube furnace play within a Vapor Transport Deposition (VTD) system? Essential Role in Thin Film Growth

- What are the functions of a quartz tube fixed-bed reactor? Ensure Precision in Catalyst Evaluation

- What is the function of autoclaves and tube reactors in hydrometallurgical leaching? Unlock Refractory Ore Potential

- How do laboratory-scale Tube Furnaces facilitate coal gasification? Precise Simulation for Industrial Success

- What role does an industrial-grade tube furnace play in the pyrolysis of nickel-modified molybdenum carbide catalysts?

- Why are vacuum sealing and quartz tubes needed for FeSiBPCCuNb heat treatment? Achieve Pure Magnetic Properties

- What role does a horizontal tube furnace play in the carbonization of SiC-C preforms? Optimize Material Structural Yield

- Why is a high-precision tube furnace required during Fe-Mn catalyst synthesis? Control Morphology and CNF Quality