Laboratory-scale Tube Furnaces facilitate coal gasification research by providing a precise, high-temperature environment that replicates the conditions of industrial reactors. By introducing controlled mixtures of oxygen or steam, these furnaces enable researchers to transform solid fuels into synthesis gas (hydrogen and carbon monoxide). This capability allows for the detailed analysis of reaction efficiency and ash behavior on a manageable scale before attempting industrial implementation.

By mimicking the thermal and atmospheric conditions of fluid-bed or entrained-flow reactors, tube furnaces allow researchers to optimize the conversion of coal into energy while solving critical efficiency challenges prior to scale-up.

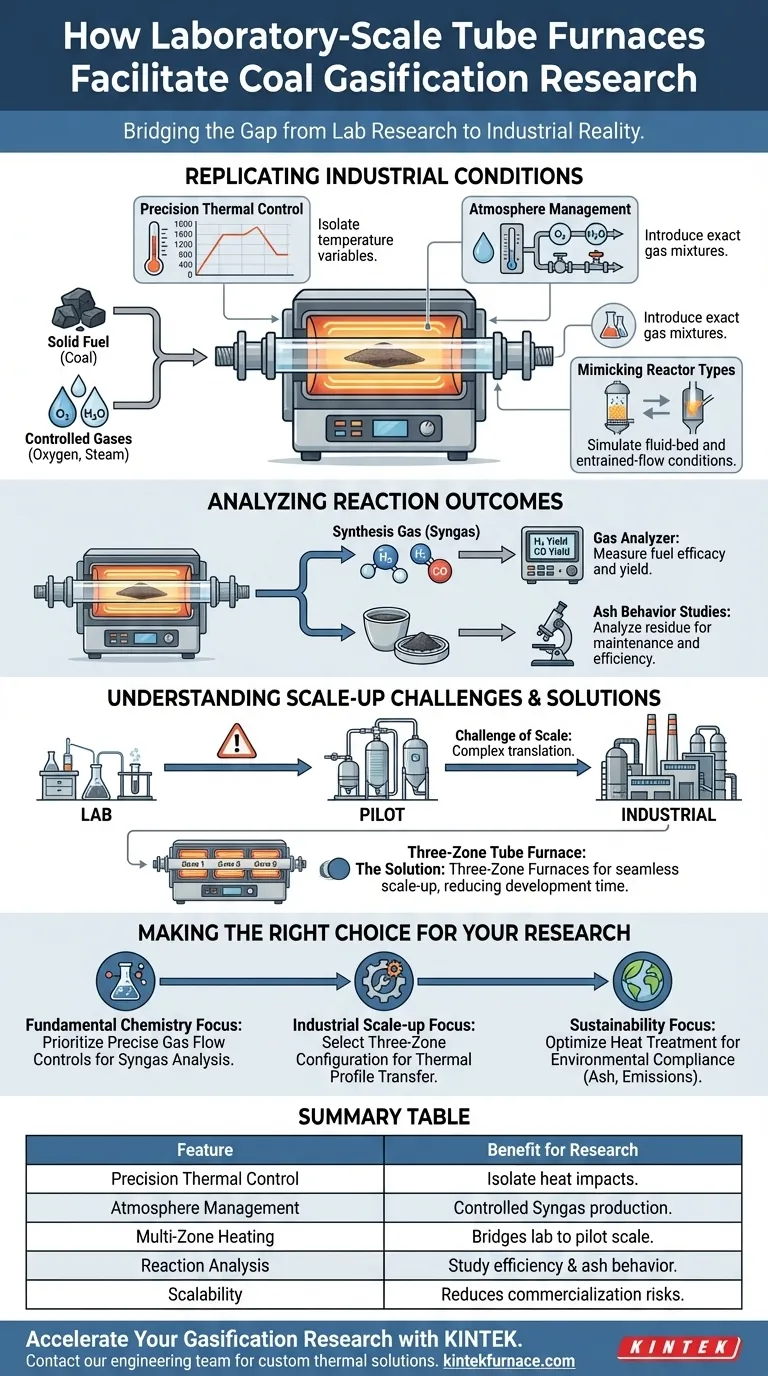

Replicating Industrial Conditions

Precision Thermal Control

Tube furnaces create a stable thermal environment essential for studying high-temperature reactions. This allows researchers to isolate specific temperature variables to understand how heat impacts the gasification process.

Atmosphere Management

The core of gasification is not just heat, but the reaction with specific gases. These furnaces allow for the introduction of exact mixtures of oxygen or steam. This controlled atmosphere is necessary to drive the chemical transformation of solid coal.

Mimicking Reactor Types

Researchers use these units to simulate the specific conditions found in larger systems, such as fluid-bed or entrained-flow reactors. This simulation ensures that data gathered in the lab is relevant to real-world industrial machinery.

Analyzing Reaction Outcomes

Synthesis Gas Production

The primary goal of these simulations is observing the conversion of solid fuel into synthesis gas (syngas). Researchers can measure the yield of hydrogen and carbon monoxide to determine the efficacy of the fuel source.

Ash Behavior Studies

Beyond the gas produced, the solid byproduct is equally important. The furnace allows for the analysis of the resulting ash behavior under heat. Understanding how ash reacts is critical for predicting maintenance needs and efficiency losses in full-scale operations.

Understanding the Trade-offs and Scale-up

The Challenge of Scale

While tube furnaces provide excellent data, transferring processes from a static lab environment to a dynamic industrial plant can be complex. The "perfect" lab conditions must be translated carefully to avoid process integrity issues during commercialization.

The Role of Three-Zone Furnaces

To mitigate scaling risks, three-zone tube furnaces are often utilized. These configurations offer seamless scale-up capabilities, bridging the gap between the laboratory and pilot or production phases.

Reducing Development Time

Using the correct furnace configuration allows processes perfected in the lab to transfer more easily to larger scales. This reduces the overall development time and accelerates the commercialization of new energy technologies.

Making the Right Choice for Your Research

To maximize the value of your simulation data, align your equipment choice with your specific research outcomes.

- If your primary focus is fundamental chemistry: Prioritize a furnace with precise gas flow controls to accurately study the oxygen and steam reactions producing syngas.

- If your primary focus is industrial scale-up: Select a three-zone tube furnace configuration to ensure that the thermal profiles developed in the lab can be transferred to pilot production without compromising integrity.

- If your primary focus is sustainability: Use the furnace to optimize heat treatment protocols, ensuring your process meets stringent environmental regulations regarding ash and emissions.

Precise simulation at the laboratory stage is the most effective way to ensure efficiency and regulatory compliance in the final industrial process.

Summary Table:

| Feature | Benefit for Coal Gasification Research |

|---|---|

| Precision Thermal Control | Isolate temperature variables to understand heat impacts on reactions. |

| Atmosphere Management | Controlled introduction of oxygen/steam for syngas (H2 and CO) production. |

| Multi-Zone Heating | Three-zone configurations bridge the gap between lab trials and pilot production. |

| Reaction Analysis | Detailed study of fuel conversion efficiency and resulting ash behavior. |

| Scalability | Mimics fluid-bed and entrained-flow reactors to reduce commercialization risks. |

Accelerate Your Gasification Research with KINTEK

Maximize your laboratory efficiency and ensure seamless industrial scale-up with KINTEK’s high-precision thermal solutions. Backed by expert R&D and manufacturing, KINTEK offers specialized Tube, Muffle, Rotary, Vacuum, and CVD systems—all fully customizable to meet your unique coal gasification and material science requirements.

Whether you need precise gas flow control for syngas analysis or three-zone configurations for industrial simulation, our equipment provides the reliability you need to bridge the gap between lab research and production.

Ready to optimize your thermal processes? Contact KINTEK today to discuss your custom furnace needs with our engineering team.

Visual Guide

References

- Shiwei Yu, Mingjie Feng. Workflow Design and Operational Analysis of a Coal‐Based Multi‐Energy Combined Supply System for Electricity, Heating, Cooling, and Gas. DOI: 10.1002/ese3.70137

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How do high-temperature tube furnaces facilitate growth control in MoS2 LPCVD? Precision Synthesis Techniques

- Why is a horizontal tube furnace used for CVD in catalyst synthesis? Achieve Precise Nano-Material Growth

- What are the technical advantages of using an oscillating tube furnace for tellurium dioxide recovery?

- What function does a tube furnace serve in metal nitride synthesis? Achieve High-Purity Nanoparticle Growth

- What are the process advantages of using a horizontal tube pyrolysis reactor? Maximize Precision and Data Integrity

- Why is a high-temperature tube furnace used for long-term annealing of CrMnFeCoNi alloys? Achieve Chemical Homogeneity

- How does a high-temperature tube furnace ensure magnesium alloy scaffold performance? Expert Sintering Guide

- How does a tube furnace facilitate the carbonization of ZIFs while preventing oxidation? Expert Insights