A high-temperature tube furnace is primarily used to eliminate severe dendrite segregation inherent in as-cast CrMnFeCoNi alloys. By subjecting the material to sustained heating at 1100 °C for roughly 12 hours, the furnace facilitates thermal diffusion, ensuring the chemical composition becomes uniform throughout the matrix before laser processing begins.

The annealing process acts as a "structural reset" for the alloy, utilizing long-term thermal exposure to dissolve segregation patterns caused during casting. This creates a chemically homogeneous foundation, which is an absolute prerequisite for achieving consistent, high-quality results during subsequent laser remelting.

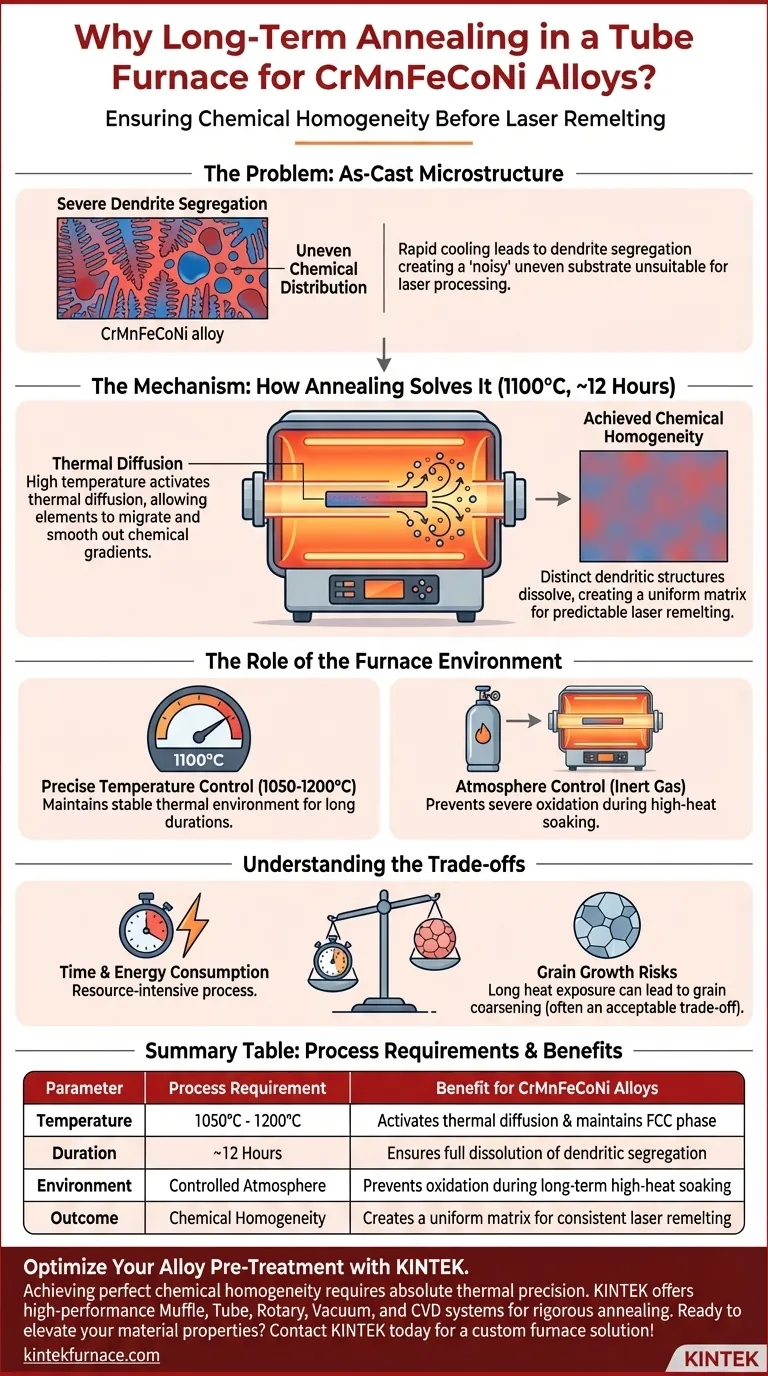

The Problem: As-Cast Microstructure

Severe Dendrite Segregation

When high-entropy alloys like CrMnFeCoNi are initially produced (often via vacuum arc melting), they cool rapidly.

This rapid cooling leads to dendrite segregation, where the chemical elements are not distributed evenly across the material.

If left untreated, these inconsistencies create a "noisy" uneven substrate. Performing laser remelting on such a surface would yield unpredictable and suboptimal modifications.

The Mechanism: How Annealing Solves It

Thermal Diffusion

The tube furnace provides the energy needed to activate thermal diffusion mechanisms.

By holding the temperature at 1100 °C, the atoms within the alloy gain enough kinetic energy to move freely.

Over the 12-hour duration, elements migrate from areas of high concentration to areas of low concentration, effectively smoothing out the chemical gradients.

Achieving Chemical Homogeneity

The result of this diffusion is a significant improvement in chemical homogeneity.

The distinct, segregated dendritic structures dissolve, leaving behind a uniform matrix.

This uniformity is crucial because it ensures that when the laser hits the surface later, it interacts with a consistent material, leading to predictable and optimized surface properties.

The Role of the Furnace Environment

Precise Temperature Control

A high-temperature tube furnace is selected because it offers a highly stable thermal environment.

References indicate that for specific goals, such as adjusting grain size or ensuring a stable single-phase face-centered cubic (FCC) structure, precise temperatures (ranging from 1050 °C to 1200 °C) are required.

The tube furnace maintains this stability over the long "soaking" periods required for solid-state diffusion to complete.

Understanding the Trade-offs

Time and Energy Consumption

This process is resource-intensive. Running a furnace at 1100 °C for 12 hours represents a significant energy cost and adds time to the production cycle.

Grain Growth Risks

While the primary goal is homogenization, long-term exposure to high heat can lead to grain coarsening.

While you eliminate chemical segregation, you may inadvertently increase the grain size. This is often an acceptable trade-off to ensure the chemical matrix is uniform for the laser process.

Atmosphere Control

Although not explicitly detailed in the primary text regarding the annealing step, tube furnaces are typically used to control the atmosphere (using inert gases).

Without this control, holding an alloy at 1100 °C would lead to severe oxidation, undermining the purpose of the treatment.

Making the Right Choice for Your Goal

To ensure your CrMnFeCoNi alloy is properly prepared, match your furnace parameters to your specific structural requirements.

- If your primary focus is Chemical Homogeneity: Prioritize the 1100 °C soak for 12 hours to maximize thermal diffusion and fully eliminate dendrite segregation.

- If your primary focus is Grain Size Control: Consider slightly lower temperatures (e.g., 1050 °C) to facilitate recrystallization while preventing excessive grain growth, provided segregation is managed.

- If your primary focus is Phase Stability: Ensure the temperature is sufficient to maintain the single-phase FCC structure, avoiding the interference of multiphase structures in your final analysis.

A uniform starting material is the single most important factor in determining the success of subsequent laser surface modifications.

Summary Table:

| Parameter | Process Requirement | Benefit for CrMnFeCoNi Alloys |

|---|---|---|

| Temperature | 1050°C - 1200°C | Activates thermal diffusion & maintains FCC phase |

| Duration | ~12 Hours | Ensures full dissolution of dendritic segregation |

| Environment | Controlled Atmosphere | Prevents oxidation during long-term high-heat soaking |

| Outcome | Chemical Homogeneity | Creates a uniform matrix for consistent laser remelting |

Optimize Your Alloy Pre-Treatment with KINTEK

Achieving perfect chemical homogeneity in high-entropy alloys like CrMnFeCoNi requires absolute thermal precision. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems designed to handle rigorous 1100°C+ annealing cycles with ease.

Whether you need to eliminate dendrite segregation or control grain growth, our customizable lab high-temp furnaces provide the stable environment your research demands.

Ready to elevate your material properties? Contact KINTEK today for a custom furnace solution!

Visual Guide

References

- Ajay Talbot, Yu Zou. Laser Remelting of a CrMnFeCoNi High‐Entropy Alloy: Effect of Energy Density on Elemental Segregation. DOI: 10.1002/adem.202501194

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- How are multi zone tube furnaces used in ceramics, metallurgy and glass research? Unlock Precise Thermal Control for Advanced Materials

- What role does a high-temperature tube furnace play in biomass-derived carbon? Unlock Advanced Material Synthesis

- What is the role of a Tube Furnace or Rotary Furnace in hydrogen reduction roasting? Optimize Lithium Recovery Efficiency.

- How do laboratory tube furnaces ensure solar-grade silicon quality? Master Pre-treatment for Purity

- Why is a quartz tube used for vacuum sealing GeTe synthesis? Ensure Material Purity and Stoichiometric Precision

- How is tantalum disulfide prepared using a tube furnace? Master the Two-Step Synthesis for High-Quality Crystals

- How does an industrial-grade tube furnace contribute to the crystallization of Selenium foam? Master High-Crystallinity

- Can a vacuum tube furnace be used with controlled gas atmospheres? Yes, for precise high-temperature processing.