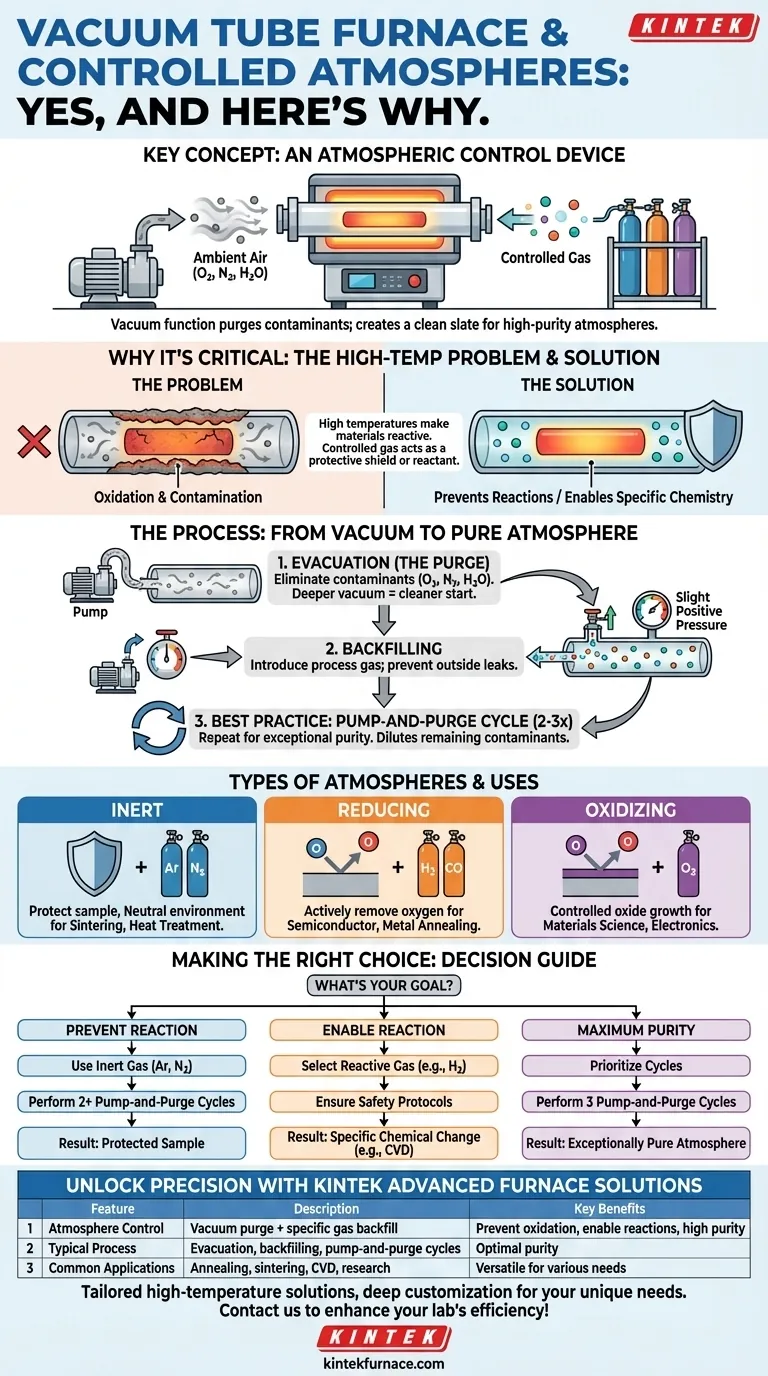

Yes, and this capability is a primary reason for their use. A vacuum tube furnace is expertly designed not just to create a vacuum, but to use that vacuum as a precursor for introducing a highly controlled gas atmosphere. This process allows for high-temperature work in environments free from the reactive elements of ambient air, such as oxygen and water vapor.

A vacuum tube furnace is fundamentally an atmospheric control device. The vacuum function serves to purge unwanted ambient gases, creating a clean slate for introducing a specific, high-purity atmosphere required for your process.

Why a Controlled Atmosphere is Critical

At the high temperatures achieved in a tube furnace, materials become far more reactive. Exposing a sample to ambient air under these conditions can lead to undesirable and uncontrolled outcomes.

Preventing Oxidation and Contamination

The most common goal is to prevent oxidation. Oxygen in the air will readily react with many materials at high temperatures, forming oxides that can compromise the structural, electrical, or chemical properties of your sample.

By first evacuating the air and then backfilling with an inert gas like Argon or Nitrogen, you create a protective environment that shields the material from these unwanted reactions.

Enabling Specific Chemical Reactions

Many advanced processes require a specific gas to act as a reactant or catalyst. A controlled atmosphere allows you to introduce gases that are essential for the desired chemical transformation.

This is fundamental for applications like annealing in a reducing atmosphere (using Hydrogen) to remove oxides, or for chemical vapor deposition (CVD), where precursor gases react to form a solid film.

The Process: From Vacuum to Controlled Atmosphere

Achieving a pure atmosphere is a deliberate, multi-step process. Simply flowing gas into the tube is insufficient for high-purity applications.

Step 1: Evacuation (The Purge)

The process always begins by using a vacuum pump to remove the air from the sealed furnace tube. The primary purpose of this step is to eliminate atmospheric contaminants—principally oxygen, nitrogen, and water vapor.

A deeper vacuum removes more of these contaminants, paving the way for a purer final atmosphere.

Step 2: Backfilling with Process Gas

Once a sufficient vacuum is reached, the vacuum valve is closed, and the desired gas is introduced into the tube through a gas inlet system, typically managed by a flow controller.

The chamber is filled to a slight positive pressure to prevent any outside air from leaking back in.

Best Practice: The Pump-and-Purge Cycle

For optimal purity, do not stop at one cycle. The most effective method is to repeat the process: pump down to a vacuum, backfill with your desired gas, and then pump down to a vacuum again.

Repeating this pump-and-purge cycle 2-3 times significantly dilutes any remaining contaminants, resulting in an exceptionally pure atmosphere for your experiment.

Types of Atmospheres and Their Uses

A vacuum tube furnace can be configured to handle a wide range of gas environments, depending on the sealing components and gas delivery system.

Inert Atmospheres

Gases like Argon (Ar) and Nitrogen (N2) are used when the goal is simply to protect the sample from any chemical reaction. They provide a neutral, non-reactive environment for processes like sintering or heat treatment.

Reducing Atmospheres

Gases like Hydrogen (H2) or Carbon Monoxide (CO) are used to actively remove oxygen from a material. This is common in semiconductor processing and metal annealing, where surface oxides must be eliminated.

Oxidizing Atmospheres

In some cases, a controlled reaction with oxygen is the desired outcome. A furnace can be used to introduce a precise amount of Oxygen (O2) to grow specific oxide layers on a substrate, a common technique in materials science and electronics.

Making the Right Choice for Your Goal

Selecting the correct atmosphere and procedure is determined entirely by your process objective.

- If your primary focus is preventing any reaction: Use a high-purity inert gas like Argon and perform at least two pump-and-purge cycles before heating.

- If your primary focus is enabling a specific chemical change: Select the appropriate reactive gas (e.g., hydrogen for reduction) and ensure your system and safety protocols are equipped for its handling.

- If your primary focus is achieving maximum purity: The number of pump-and-purge cycles is your most powerful tool; three cycles are better than one.

Mastering atmospheric control transforms your vacuum tube furnace from a simple heater into a precise chemical reactor.

Summary Table:

| Feature | Description |

|---|---|

| Atmosphere Control | Uses vacuum to purge air and introduce specific gases like Argon, Hydrogen, or Oxygen. |

| Key Benefits | Prevents oxidation, enables chemical reactions (e.g., CVD), and ensures high purity. |

| Typical Process | Evacuation, backfilling, and pump-and-purge cycles for optimal purity. |

| Common Applications | Annealing, sintering, chemical vapor deposition (CVD), and materials science research. |

Unlock Precision in Your Lab with KINTEK's Advanced Furnace Solutions

Are you tackling high-temperature processes that demand exact atmospheric control? KINTEK specializes in providing tailored high-temperature furnace solutions, including Vacuum & Atmosphere Furnaces and CVD/PECVD Systems. Leveraging our exceptional R&D and in-house manufacturing, we offer deep customization to meet your unique experimental needs—whether you're preventing oxidation, enabling specific reactions, or achieving maximum purity. Don't let atmospheric challenges hold back your research—contact us today to discuss how our expertise can enhance your lab's efficiency and results!

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- How is the sealing performance of an experimental box type atmosphere furnace enhanced? Boost Purity with Advanced Sealing Systems

- How does a batch type controlled atmosphere furnace operate? Master Precision Heat Treatment for Superior Materials

- How do argon and nitrogen protect samples in vacuum furnaces? Optimize Your Thermal Process with the Right Gas

- What are the primary inert gases used in vacuum furnaces? Optimize Your Heat Treatment Process

- What are the development prospects of atmosphere box furnaces in the aerospace industry? Unlock Advanced Material Processing for Aerospace Innovation