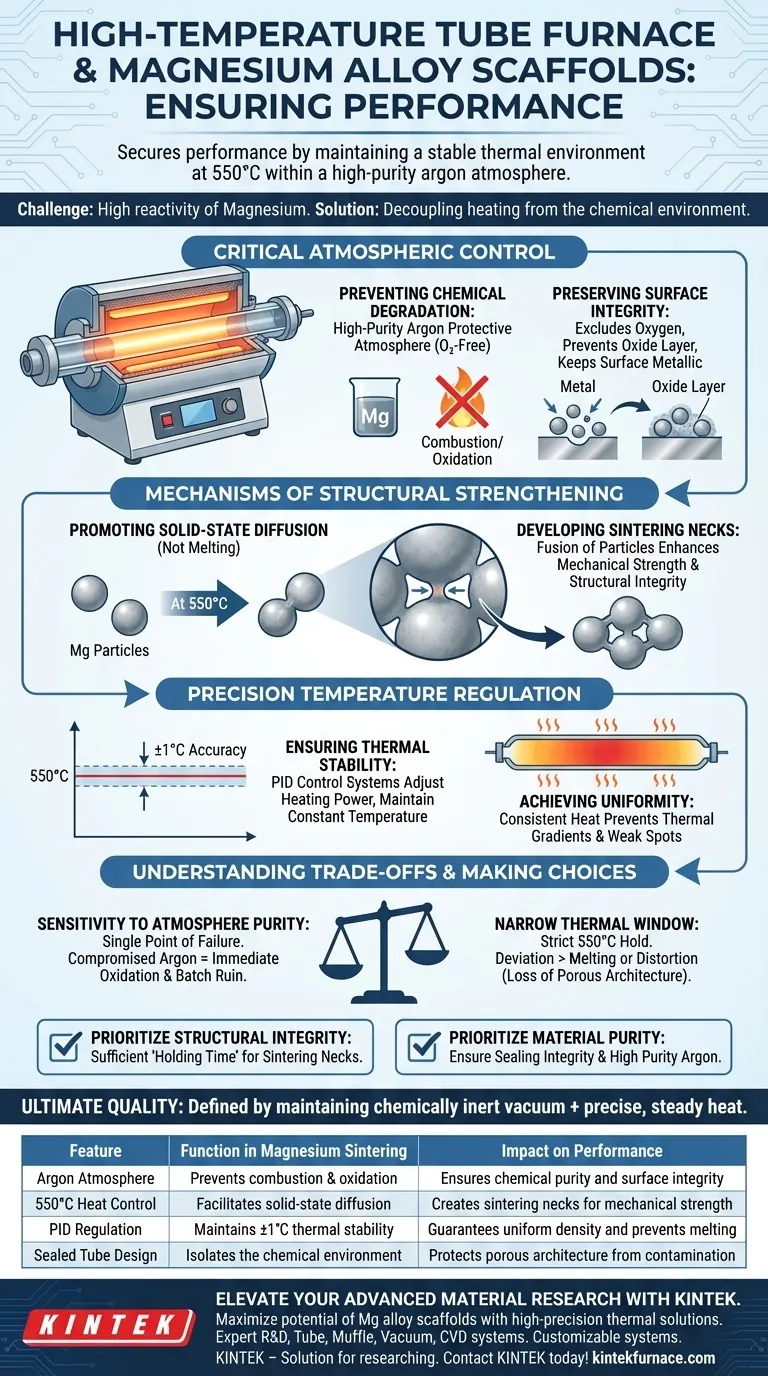

A high-temperature tube furnace secures magnesium alloy performance by maintaining a stable thermal environment at 550°C within a high-purity argon atmosphere. This strictly oxygen-free isolation prevents the magnesium from undergoing dangerous combustion or intense oxidation, while sustained heat drives solid-state diffusion to fuse metal particles into a robust, integrated structure.

The core challenge in sintering magnesium is its high reactivity; the furnace solves this by decoupling the heating process from the chemical environment, allowing particles to bond physically without degrading chemically.

The Critical Role of Atmospheric Control

Preventing Chemical Degradation

Magnesium is highly reactive and prone to combustion or rapid oxidation at elevated temperatures.

The tube furnace mitigates this risk by utilizing a high-purity argon protective atmosphere.

This creates a strictly oxygen-free environment, ensuring the material remains chemically pure throughout the heating cycle.

Preserving Surface Integrity

If oxygen were present, an oxide layer would form on the metal particles, inhibiting the sintering process.

By excluding oxygen, the furnace ensures that the surface of the magnesium alloy remains metallic and reactive only to itself.

Mechanisms of Structural Strengthening

Promoting Solid-State Diffusion

The primary goal of sintering is not to melt the metal, but to fuse it.

At the specific temperature of 550°C, the furnace facilitates solid-state diffusion between magnesium particles.

Developing Sintering Necks

This diffusion process leads to the formation of "sintering necks," which are bridges where individual particles merge.

This fusion significantly enhances the mechanical strength and structural integrity of the porous scaffolds, transforming loose powder into a cohesive unit.

Precision Temperature Regulation

Ensuring Thermal Stability

For diffusion to occur uniformly, the temperature must remain constant over an extended period.

Advanced tube furnaces utilize PID (Proportional-Integral-Derivative) control systems to automatically adjust heating power.

This technology maintains the stability of the temperature field, often achieving accuracy within ±1℃.

Achieving Uniformity

Consistent material performance depends on every part of the scaffold experiencing the same thermal history.

The furnace design ensures that the 550°C heat is applied uniformly, preventing weak spots caused by thermal gradients.

Understanding the Trade-offs

Sensitivity to Atmosphere Purity

The reliance on a protective atmosphere creates a single point of failure.

If the argon supply is compromised or the tube seals leak even slightly, the magnesium will oxidize immediately, ruining the batch.

The Narrow Thermal Window

Magnesium has a relatively low melting point compared to other structural metals.

There is a strict trade-off between sufficient heat for diffusion and too much heat, which causes melting or distortion.

The temperature must be held strictly at 550°C; deviation can result in a loss of the scaffold's porous architecture.

Making the Right Choice for Your Goal

To maximize the performance of magnesium alloy scaffolds, prioritize these operational parameters:

- If your primary focus is Structural Integrity: Ensure the "holding time" at 550°C is sufficient to allow full development of sintering necks via solid-state diffusion.

- If your primary focus is Material Purity: Prioritize the integrity of the sealing system and the purity grade of the argon gas to prevent any trace oxidation.

Ultimately, the quality of the final scaffold is defined by the furnace's ability to maintain a chemically inert vacuum while delivering precise, steady heat.

Summary Table:

| Feature | Function in Magnesium Sintering | Impact on Performance |

|---|---|---|

| Argon Atmosphere | Prevents combustion & oxidation | Ensures chemical purity and surface integrity |

| 550°C Heat Control | Facilitates solid-state diffusion | Creates sintering necks for mechanical strength |

| PID Regulation | Maintains ±1℃ thermal stability | Guarantees uniform density and prevents melting |

| Sealed Tube Design | Isolates the chemical environment | Protects porous architecture from contamination |

Elevate Your Advanced Material Research with KINTEK

Maximize the potential of your magnesium alloy scaffolds with high-precision thermal solutions. Backed by expert R&D and industry-leading manufacturing, KINTEK provides high-performance Tube, Muffle, Vacuum, and CVD systems specifically designed for sensitive materials. Whether you require standard lab high-temp furnaces or fully customizable systems tailored to your unique atmospheric needs, our technology ensures the stability and purity your research demands.

Ready to optimize your sintering process? Contact KINTEK today to consult with our specialists!

Visual Guide

References

- Omnia Ghabour, Mona Hussein Mohy El Din. Fabrication and evaluation of the mechanical properties of reinforced biodegradable magnesium scaffolds using the space holder method. DOI: 10.21608/adjalexu.2024.290833.1507

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- Why is it necessary to perform annealing in a tube furnace with a nitrogen atmosphere for VO2@AlF3 core-shell powder?

- What are the specific requirements for quartz tubes used in fixed-bed reactors? Optimize Your CeAlOx/Ni-Foam Performance

- What is the significance of using a tubular furnace in waste salt pyrolysis research? Precision for High-Fidelity Data

- What is the working principle of a vacuum tube furnace? Master Precise High-Temperature Processing

- What are the technical advantages of using a tube furnace for carbon nitride? Master Advanced Defect Engineering

- What are the primary applications of tube furnaces? Unlock Precision in High-Temperature Processing

- Why is a stable nitrogen flow required in a tube furnace for hydrochar carbonization? Ensure High-Carbon Purity

- What are the two core technical functions of a vacuum tube sintering furnace? Mastering Porous Alloy Engineering