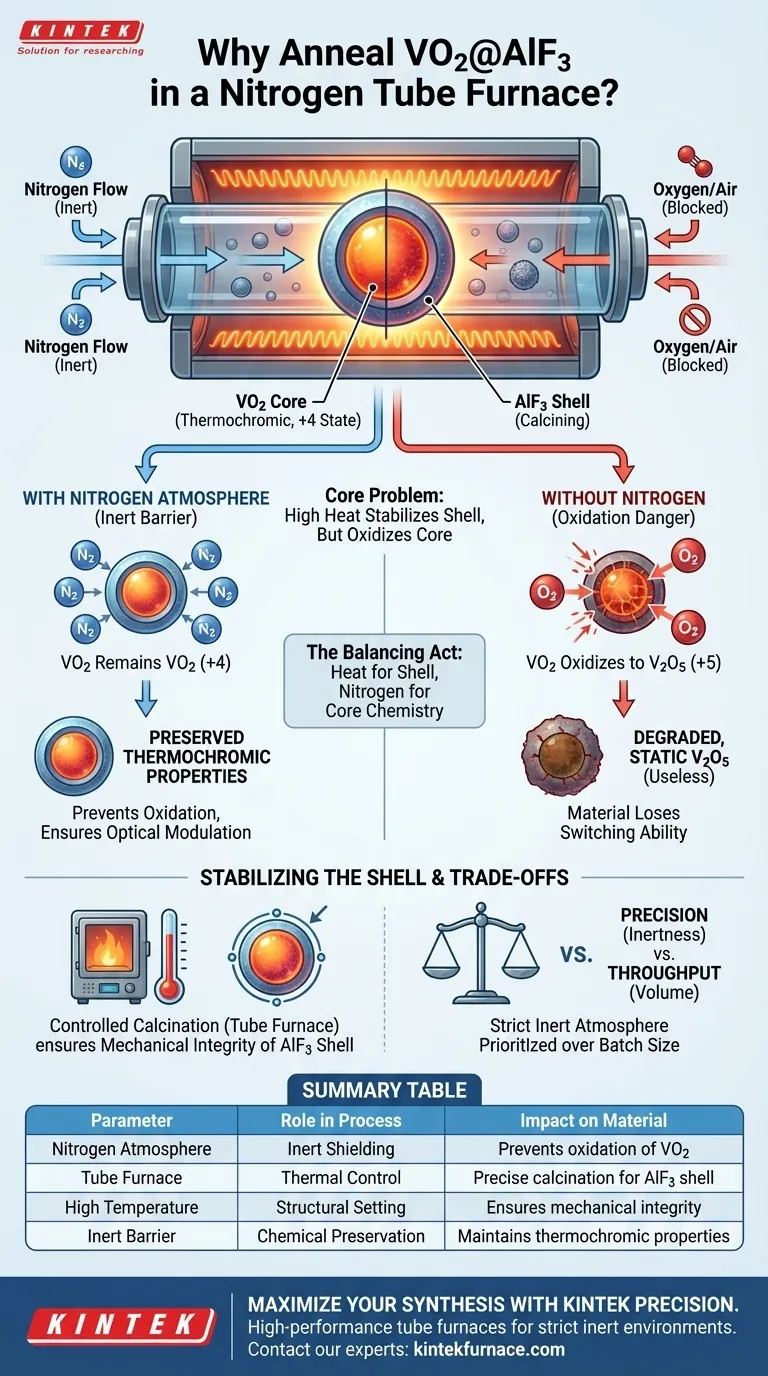

Annealing in a tube furnace with a nitrogen atmosphere is critical for stabilizing the protective coating of the material without compromising its active core. This process utilizes precise high-temperature control to calcine the aluminum fluoride ($AlF_3$) shell while the inert nitrogen environment strictly prevents the vanadium dioxide ($VO_2$) core from oxidizing into unwanted chemical states.

Core Takeaway: This specific annealing setup solves a fundamental contradiction: it applies the high heat necessary to stabilize the outer shell while simultaneously shielding the inner core from oxygen to preserve its thermochromic capabilities.

Protecting the Core Chemistry

The primary challenge in preparing $VO_2@AlF_3$ powder is that the active core is highly sensitive to oxygen at the temperatures required for synthesis.

The Danger of Oxidation

At high temperatures, vanadium is prone to changing its oxidation state. Without a protective atmosphere, the $+4$ oxidation state of vanadium in the $VO_2$ core will oxidize to the $+5$ state.

Preventing Unwanted Phase Changes

This oxidation reaction converts the desirable vanadium dioxide ($VO_2$) into vanadium pentoxide ($V_2O_5$). Nitrogen acts as an inert barrier, displacing oxygen and effectively blocking this chemical reaction.

Preserving Critical Properties

The utility of this material relies entirely on the specific properties of the $VO_2$ core. If it oxidizes to $V_2O_5$, the material loses its thermochromic phase transition properties. Nitrogen ensures the material retains its ability to modulate optical signals.

Stabilizing the Outer Shell

While the nitrogen protects the core, the tube furnace provides the thermal environment necessary to finalize the composite structure.

Controlled Calcination

The $AlF_3$ coating layer requires calcination to become stable. The tube furnace allows for a precisely controlled high-temperature environment to facilitate this process.

Ensuring Durability

By subjecting the powder to this specific heat treatment, the coating layer is properly set. This stabilization is essential for the mechanical integrity of the core-shell structure.

Understanding the Trade-offs

The process requires a strict balance between thermal requirements and chemical isolation.

The Consequence of Atmosphere Leaks

If the nitrogen atmosphere is compromised even slightly, the high heat will accelerate oxidation. This results in a material that is structurally sound (the shell is calcined) but functionally useless (the core is degraded).

Precision vs. Throughput

Using a tube furnace allows for high precision but often processes smaller batches compared to industrial kilns. This trade-off is necessary because maintaining a strictly inert atmosphere is prioritized over volume to guarantee the survival of the $VO_2$ phase.

Making the Right Choice for Your Goal

To ensure the success of your $VO_2@AlF_3$ preparation, prioritize the parameters below based on your specific objectives.

- If your primary focus is Optical Performance: Ensure the nitrogen flow is continuous and the seal is perfect to prevent the formation of static, non-switching $V_2O_5$.

- If your primary focus is Structural Stability: adhere strictly to the required calcination temperatures to fully stabilize the $AlF_3$ shell against environmental wear.

Success in this synthesis depends on using heat to build the shell while using nitrogen to freeze the chemistry of the core.

Summary Table:

| Parameter | Role in Process | Impact on Material |

|---|---|---|

| Nitrogen Atmosphere | Inert Shielding | Prevents oxidation of $VO_2$ (+4) to $V_2O_5$ (+5) |

| Tube Furnace | Thermal Control | Provides precise calcination for the $AlF_3$ shell |

| High Temperature | Structural Setting | Ensures mechanical integrity and durability of the coating |

| Inert Barrier | Chemical Preservation | Maintains thermochromic phase transition properties |

Maximize Your Material Synthesis with KINTEK Precision

Don't let oxidation compromise your core-shell research. KINTEK provides high-performance tube and vacuum furnace systems specifically designed to maintain the strict inert environments required for sensitive chemical transitions. Backed by expert R&D and manufacturing, we offer customizable high-temp solutions—including Tube, Muffle, Rotary, and CVD systems—to ensure your $VO_2$ particles retain their critical thermochromic properties.

Ready to achieve perfect annealing results? Contact our technical experts today to find the ideal furnace for your unique lab requirements!

Visual Guide

References

- Lingfeng Jiang, Li Zhao. Chemical Deposition Method for Preparing VO2@AlF3 Core–Shell-Structured Nanospheres for Smart Temperature-Control Coating. DOI: 10.3390/coatings15091045

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What technical features make a laboratory horizontal tube furnace an ideal reaction device for oil sludge studies?

- What function does the annealing treatment in a high-temperature quartz-tube furnace serve? Optimizing Glass Ceramics

- What are the benefits of a vertical tube furnace? Maximize Space and Purity in Your Lab

- What is the core function of a high-temperature tube furnace in converting Fe2O3/GO? Mastering Material Transformation

- How do split tube furnaces provide access to the chamber? Unlock Easy Sample Handling for Your Lab

- What role does a tube furnace play in the high-temperature heat treatment stage of catalyst fabrication?

- What is a tube furnace and what is its primary use? Achieve Precision High-Temp Processing for Your Lab

- What are the key functions of a high-temperature tubular furnace? Master High-Entropy Alloy Catalyst Synthesis