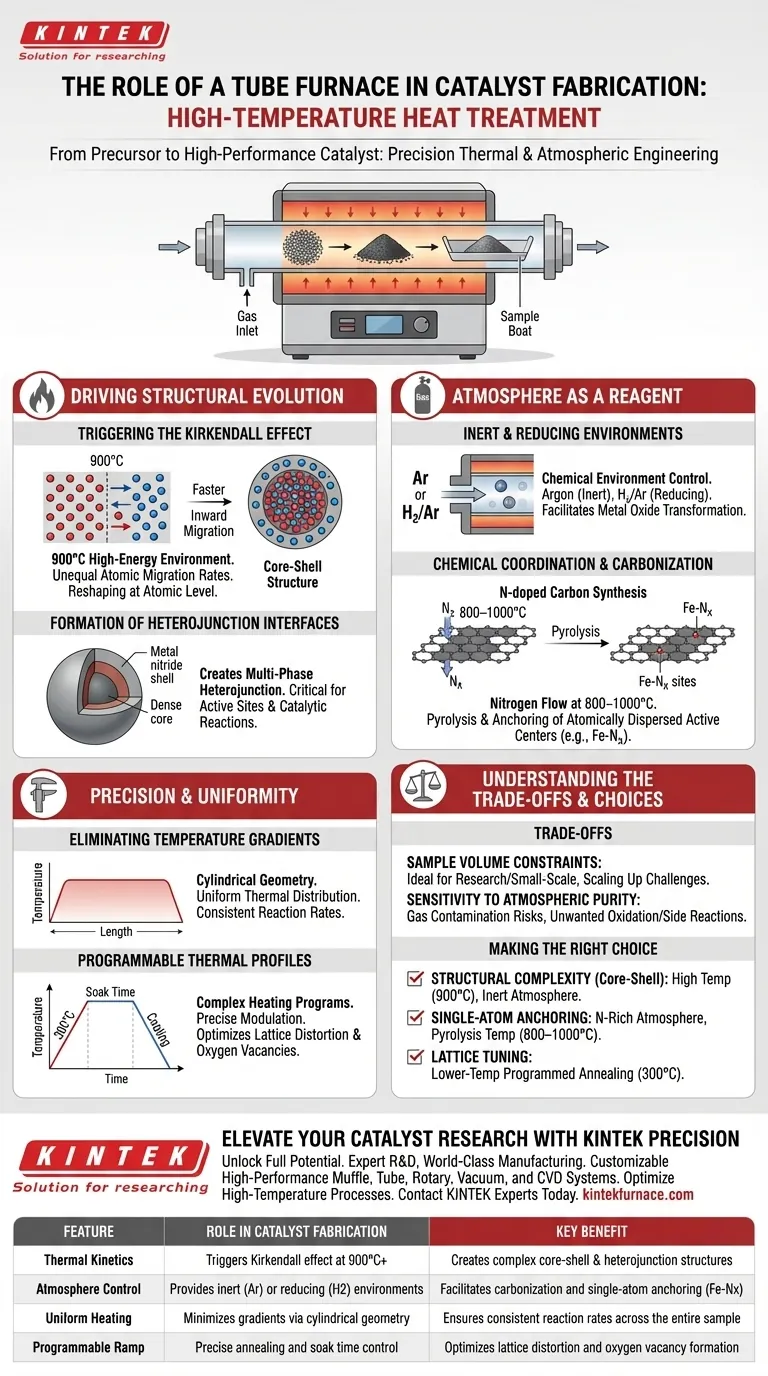

A tube furnace serves as a high-precision reactor, distinct from standard heating equipment due to its ability to simultaneously control thermal kinetics and atmospheric composition. Specifically, in catalyst fabrication, it creates a 900 °C inert Argon environment that triggers the Kirkendall effect, a phenomenon essential for engineering complex material structures.

Core Takeaway The tube furnace is the critical instrument for atomic-level structural engineering. By combining precise thermal profiles with controlled atmospheres, it manipulates atomic migration rates to create multi-phase heterojunctions, such as core-shell structures with optimized active sites.

Driving Structural Evolution

The primary role of the tube furnace in this context is to induce specific structural changes that do not occur under standard heating conditions.

Triggering the Kirkendall Effect

The furnace provides the high-energy environment (e.g., 900 °C) required to initiate the Kirkendall effect.

This effect relies on the unequal migration rates of different metal atoms within the material.

By sustaining this temperature, the furnace drives faster-moving atoms outward and slower-moving atoms inward, reshaping the catalyst at the atomic level.

Formation of Heterojunction Interfaces

This differential atomic movement results in the formation of unique geometries, such as a metal nitride shell surrounding a dense core.

This process creates a multi-phase heterojunction interface.

This interface is critical because it exposes specific active sites necessary for catalytic reactions, effectively turning a raw precursor into a functional high-performance catalyst.

Atmosphere as a Reagent

Beyond temperature, the tube furnace acts as a chamber for chemical environment control. The atmosphere is not just a protective blanket; it is an active participant in the synthesis.

Inert and Reducing Environments

The furnace allows for the introduction of specific gases, such as Argon (inert) or mixtures like Hydrogen/Argon (reducing).

As noted in broader applications, a reducing atmosphere (e.g., 5% H2) can facilitate the transformation of metal oxide precursors into high-entropy alloys.

Chemical Coordination and Carbonization

In processes involving nitrogen-doped carbon (Fe–N–C), the furnace’s atmosphere control is vital.

Under a nitrogen flow at high temperatures (e.g., 800–1000 °C), the furnace facilitates pyrolysis.

This expels volatile decomposition products and promotes the coordination of metal salts, anchoring atomically dispersed active centers (like Fe-Nx) into the substrate.

Precision and Uniformity

The "tube" design is not arbitrary; it is engineered for consistency, which is paramount for experimental integrity.

Eliminating Temperature Gradients

The cylindrical geometry ensures uniform thermal distribution along the length of the heated zone.

This minimizes temperature gradients that could otherwise lead to uneven reaction rates across the sample.

Programmable Thermal Profiles

Advanced tube furnaces allow for complex heating programs, including specific ramp rates and soak times.

For example, a programmed annealing at 300 °C can induce lattice distortion or oxygen vacancies.

This precise modulation optimizes the charge distribution of the catalyst, enhancing its ability to adsorb reactant molecules.

Understanding the Trade-offs

While the tube furnace is a powerful tool for synthesis, it presents specific limitations that must be managed.

Sample Volume Constraints

The geometry of the tube limits the physical size of the sample batch.

While ideal for research and small-scale precision synthesis, scaling up the unique structures formed via the Kirkendall effect (like the core-shell architecture) to mass production quantities requires overcoming significant spatial constraints.

Sensitivity to Atmospheric Purity

The quality of the catalyst is strictly bound to the purity of the gas flow.

Any contamination in the gas supply or leaks in the vacuum system can compromise the inert or reducing environment.

This can lead to unwanted oxidation or side reactions that destroy the intended atomic structure, such as the FCC phase or the single-atom dispersion.

Making the Right Choice for Your Goal

The specific settings of your tube furnace determine the final identity of your catalyst.

- If your primary focus is Structural Complexity (Core-Shell): Prioritize high temperatures (900 °C) and inert atmospheres to trigger the Kirkendall effect and exploit migration rate differences.

- If your primary focus is Single-Atom Anchoring: Utilize a nitrogen-rich atmosphere at pyrolysis temperatures (800–1000 °C) to carbonize frameworks and coordinate metal sites.

- If your primary focus is Lattice Tuning: Employ lower-temperature programmed annealing (300 °C) to introduce lattice distortions and oxygen vacancies for optimized adsorption.

The tube furnace is not just a heater; it is the architect of the catalyst's active surface.

Summary Table:

| Feature | Role in Catalyst Fabrication | Key Benefit |

|---|---|---|

| Thermal Kinetics | Triggers the Kirkendall effect at 900°C+ | Creates complex core-shell & heterojunction structures |

| Atmosphere Control | Provides inert (Ar) or reducing (H2) environments | Facilitates carbonization and single-atom anchoring (Fe-Nx) |

| Uniform Heating | Minimizes gradients via cylindrical geometry | Ensures consistent reaction rates across the entire sample |

| Programmable Ramp | Precise annealing and soak time control | Optimizes lattice distortion and oxygen vacancy formation |

Elevate Your Catalyst Research with KINTEK Precision

Unlock the full potential of your material synthesis with KINTEK’s industry-leading thermal solutions. Backed by expert R&D and world-class manufacturing, we offer high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet the rigorous demands of your lab.

Whether you are engineering complex core-shell structures or anchoring single-atom active sites, KINTEK provides the precise temperature and atmospheric control your innovation deserves.

Ready to optimize your high-temperature processes? Contact our technical experts today to find the perfect furnace for your unique needs.

Visual Guide

References

- Yihan Zhang, Hyesung Park. Lanthanum‐Induced Gradient Fields in Asymmetric Heterointerface Catalysts for Enhanced Oxygen Electrocatalysis. DOI: 10.1002/adma.202511117

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- How does a high-temperature tube furnace contribute to the post-deposition processing of Ge:ZnO thin films?

- What are the technical advantages of using a Tube Furnace? Master Atmospheric Control for Solid-State Battery Research

- How does the industrial tube furnace contribute to Fe-N-C catalyst synthesis? Master High-Temperature Carbonization

- Why is a high-temperature tube furnace utilized for the calcination of nano-zinc oxide? Master Microstructure Control

- What is the role of a tube furnace in the synthesis of porous nitrogen-doped carbon (NC) supports? Maximize Catalytic Performance

- What physical conditions does a laboratory Tube Furnace provide for SOEC? Precision Heat for Solid Oxide Characterization

- How does the amount of material processed vary between batch and continuous rotary tube furnaces? Scale Your Production Efficiently

- How was the uneven heating problem in tubular furnaces solved? Achieve Perfect Heat Uniformity with Advanced Designs