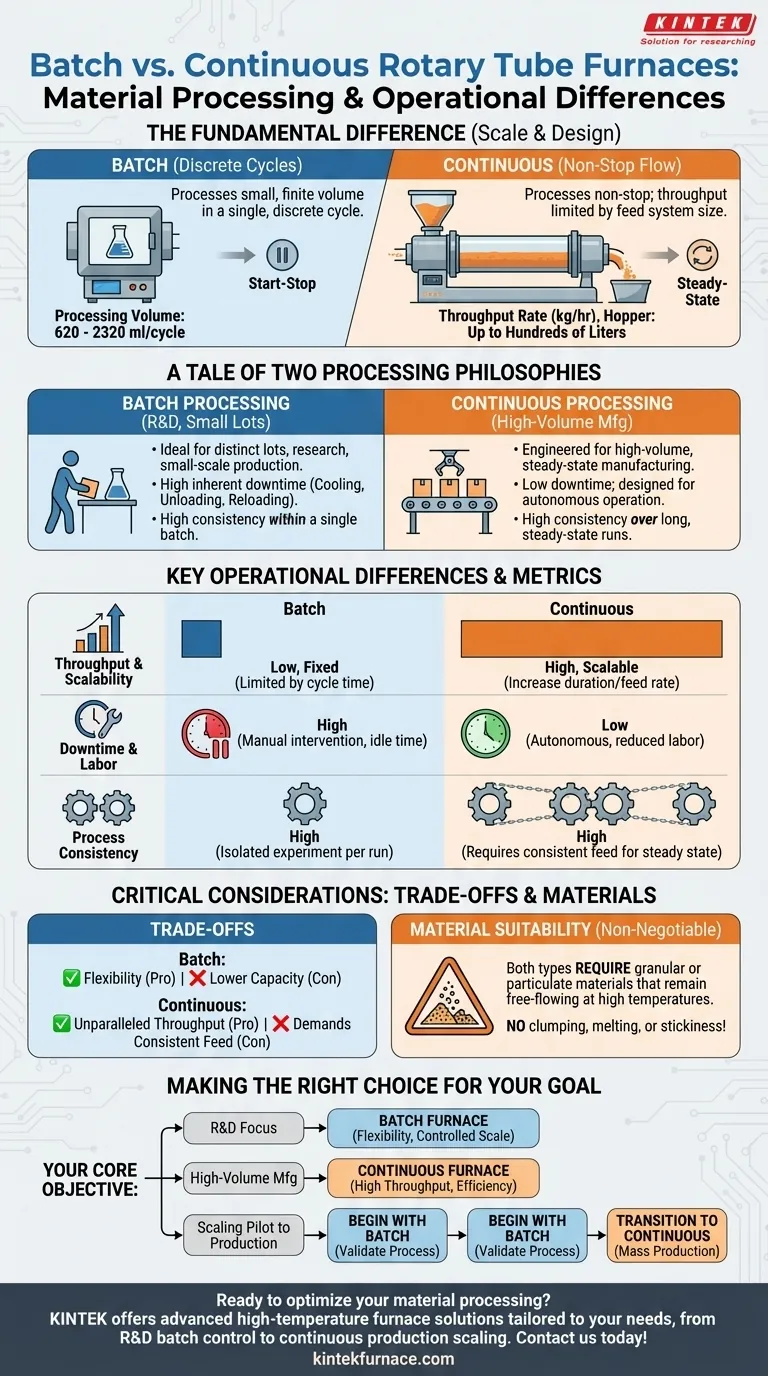

The fundamental difference in material processing between batch and continuous rotary tube furnaces is one of scale and operational design. A batch furnace processes a small, finite volume of material (typically 620 to 2320 ml) in a single, discrete cycle. In contrast, a continuous furnace processes material non-stop, with throughput limited only by the size of its feed system, which can hold from a few to several hundred liters.

Your choice between a batch and continuous furnace is not just about the amount of material, but the nature of your work. Batch processing serves research and small-scale production of distinct lots, while continuous processing is engineered for high-volume, steady-state manufacturing.

A Tale of Two Processing Philosophies

The decision between these two furnace types hinges on understanding their distinct operational models. One is designed for discrete tasks, the other for uninterrupted flow.

Defining Batch Processing

A batch furnace processes a single, specific quantity of material at a time. This "batch" is loaded into the furnace, processed under set conditions, and then fully removed.

The entire system often needs to cool down before the next batch can be loaded. This start-stop nature makes it ideal for applications where material lots must be kept separate and traceable. The typical processing volume per cycle is quite small, usually under 2.5 liters.

Defining Continuous Processing

A continuous furnace is designed for non-stop, high-volume production. Material is constantly fed into one end of the furnace and processed product is discharged from the other.

Its capacity is not measured by a single run, but by a throughput rate (e.g., kilograms per hour). The hopper size, which can be several hundred liters, determines how long the furnace can run unattended, not the total amount it can process over time.

Key Operational Differences

Beyond simple volume, the operational realities of each furnace type directly impact process efficiency, consistency, and labor requirements.

Throughput and Scalability

Batch systems have a fixed, low throughput defined by cycle time and volume. Scaling up production means running more individual cycles, which has a practical limit.

Continuous systems offer vastly superior throughput and are built for industrial scalability. Increasing production is a matter of running the system for longer periods or increasing the feed rate.

Downtime and Labor

Batch processing has inherent downtime built into its workflow. Time spent cooling, unloading, and reloading the furnace is time not spent processing material. This cycle requires repeated manual intervention.

Continuous furnaces, once stabilized, are designed for long periods of autonomous operation, significantly reducing idle time and direct labor costs per unit of material processed.

Process Consistency

With a batch system, you achieve high consistency within a single batch. It provides an excellent environment for testing variables because each run is an isolated experiment.

A continuous system is engineered to maintain a steady-state equilibrium, providing excellent product consistency over very long production runs. Achieving this steady state, however, requires a consistent feed material and stable operating parameters.

Understanding the Trade-offs and Limitations

Neither technology is universally superior; each comes with clear trade-offs that make it suitable for different applications.

The Cost of Flexibility (Batch)

The primary advantage of a batch furnace is its flexibility for research, development, and handling multiple small jobs. The trade-off is significantly lower overall production capacity and efficiency.

The Demand for Consistency (Continuous)

A continuous furnace offers unparalleled throughput but demands a highly consistent and uniform feed material to operate smoothly. It is less forgiving of variations in particle size or composition, and start-up/shut-down procedures can be more involved.

Material Suitability is Non-Negotiable

It is critical to understand that this choice is secondary to material compatibility. Both furnace types are only suitable for granular or particulate materials that remain free-flowing at high temperatures. Any material that clumps, melts, or becomes sticky will disrupt the process in either system.

Making the Right Choice for Your Goal

Your application's core objective is the deciding factor. Use this guide to determine the correct path for your needs.

- If your primary focus is Research & Development: A batch furnace provides the necessary flexibility to test different materials and process parameters on a small, controlled scale.

- If your primary focus is High-Volume Manufacturing: A continuous furnace is the only viable option for achieving the high throughput and operational efficiency required for industrial production.

- If your primary focus is Scaling from Pilot to Production: Begin with a batch furnace to validate your process and material properties, then transition to a continuous system once the parameters are locked in for mass production.

Ultimately, understanding your required scale and operational goals is the key to selecting the right furnace technology for your success.

Summary Table:

| Aspect | Batch Furnace | Continuous Furnace |

|---|---|---|

| Processing Volume | 620 ml to 2320 ml per batch | Throughput rate (e.g., kg/hour), hopper size up to hundreds of liters |

| Throughput | Low, fixed per cycle | High, scalable for long runs |

| Downtime | High (cooling, loading/unloading) | Low, designed for continuous operation |

| Consistency | High within a single batch | High over steady-state production |

| Ideal Use | R&D, small-scale production | High-volume manufacturing |

Ready to optimize your material processing? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Whether you're in research requiring precise batch control or scaling up for continuous production, our product line—including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is backed by strong deep customization capabilities to meet your unique experimental and production requirements. Contact us today to discuss how we can enhance your efficiency and achieve your goals!

Visual Guide

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What are some applications of rotary tube furnaces? Ideal for Continuous High-Temperature Material Processing

- What are the benefits of continuous sample movement in rotary tube furnaces? Boost Uniformity and Efficiency

- What are the key features of a rotary furnace? Achieve Superior Uniformity and Control

- What are the key features of rotary tube furnaces regarding heat treatment? Achieve Uniform Heating and High Throughput

- What other fields utilize rotary tube furnaces? Discover Versatile Heating Solutions for Multiple Industries