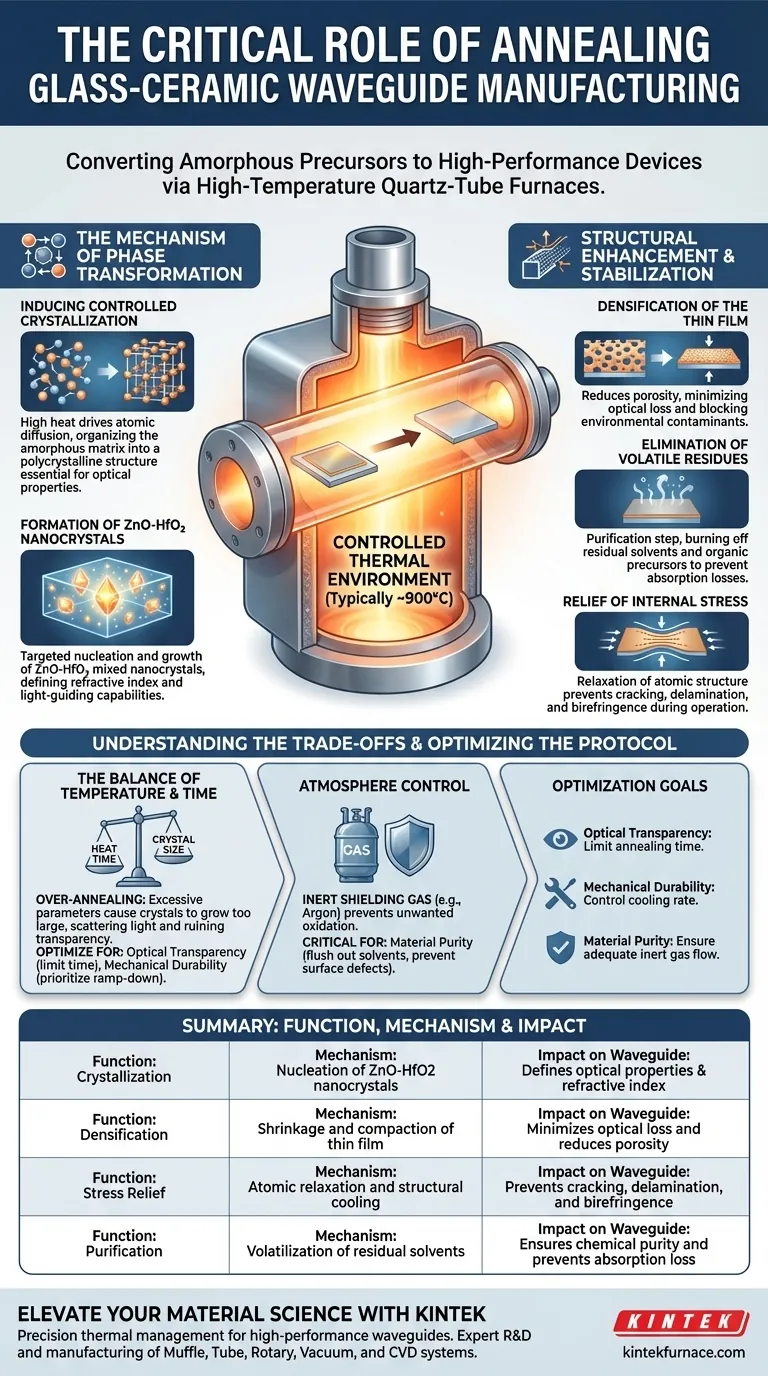

The annealing treatment serves as the critical phase-transition step that converts a raw, amorphous precursor into a high-performance glass-ceramic waveguide. By subjecting the material to a controlled thermal environment—typically around 900°C—the furnace facilitates the nucleation and growth of specific ZnO-HfO2 mixed nanocrystals. Beyond crystallization, this process mechanically stabilizes the device by densifying the thin film, driving out residual solvents, and relieving internal structural stresses.

The annealing process in a high-temperature quartz-tube furnace is the defining moment where the waveguide acquires its optical functionality. It transforms the material from a fragile, amorphous state into a robust, polycrystalline structure through precise thermal management and stress relief.

The Mechanism of Phase Transformation

Inducing Controlled Crystallization

The primary function of the furnace is to shift the material's state. The high heat drives atomic diffusion and rearrangement, forcing the atoms within the amorphous matrix to organize into a structured lattice.

This creates a polycrystalline structure that is essential for the waveguide's specific optical properties.

Formation of ZnO-HfO2 Nanocrystals

Specifically for glass-ceramic waveguides, the furnace targets the formation of ZnO-HfO2 mixed nanocrystals.

The 900°C environment provides the exact activation energy required for these specific crystals to nucleate and grow within the glass matrix, directly influencing the refractive index and light-guiding capabilities of the device.

Structural Enhancement and Stabilization

Densification of the Thin Film

Before annealing, the deposited film is often porous or loosely packed. The high temperature causes the film to shrink and compact.

This densification reduces porosity, which is vital for minimizing optical loss and preventing environmental contaminants from entering the waveguide layer.

Elimination of Volatile Residues

The manufacturing process often leaves behind residual solvents or organic precursors.

The annealing heat acts as a purification step, effectively burning off or evaporating these impurities. This ensures the final waveguide is chemically pure, preventing absorption losses during light transmission.

Relief of Internal Stress

Deposition processes can introduce significant mechanical tension within the thin film.

Annealing relaxes the atomic structure, relieving residual stresses. Without this step, the waveguide would be prone to cracking, delamination, or birefringence (unwanted double refraction) during operation.

Understanding the Trade-offs

The Balance of Temperature and Time

While high heat is necessary, it is a double-edged sword. Over-annealing (excessive time or temperature) can cause the nanocrystals to grow too large.

If crystals exceed a certain size, they begin to scatter light rather than guide it, ruining the optical transparency of the waveguide.

Atmosphere Control

The environment inside the tube is as critical as the heat. As noted in general furnace operations, the presence of oxygen at high temperatures can degrade certain semiconductor properties.

Using an inert shielding gas like argon prevents unwanted oxidation. However, failing to maintain this inert atmosphere can lead to surface defects that compromise the waveguide's stability.

Optimizing the Annealing Protocol

To achieve the best results, you must align the furnace parameters with your specific performance metrics.

- If your primary focus is Optical Transparency: Strictly limit the annealing time at 900°C to prevent the ZnO-HfO2 nanocrystals from growing large enough to cause light scattering.

- If your primary focus is Mechanical Durability: Prioritize the ramp-down rate (cooling phase) to ensure maximum stress relief and film densification without introducing thermal shock.

- If your primary focus is Material Purity: Ensure adequate gas flow (such as Argon) to flush out volatilized solvents and prevent surface oxidation during the high-heat phase.

Mastering the annealing curve is the key to balancing structural integrity with pristine optical performance.

Summary Table:

| Function | Mechanism | Impact on Waveguide |

|---|---|---|

| Crystallization | Nucleation of ZnO-HfO2 nanocrystals | Defines optical properties & refractive index |

| Densification | Shrinkage and compaction of thin film | Minimizes optical loss and reduces porosity |

| Stress Relief | Atomic relaxation and structural cooling | Prevents cracking, delamination, and birefringence |

| Purification | Volatilization of residual solvents | Ensures chemical purity and prevents absorption loss |

Elevate Your Material Science with KINTEK

Precision thermal management is the difference between a fragile precursor and a high-performance waveguide. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems tailored for the most demanding laboratory environments.

Whether you require strict atmosphere control with inert gases or precise ramp rates for nanocrystal growth, our customizable high-temperature furnaces provide the reliability you need.

Ready to optimize your annealing protocol? Contact KINTEK today to discuss your unique project requirements with our technical specialists.

Visual Guide

References

- Subhabrata Ghosh, S.N.B. Bhaktha. Optical Gain in Eu-Doped Hybrid Nanocrystals Embedded SiO2-HfO2-ZnO Ternary Glass-Ceramic Waveguides. DOI: 10.3390/spectroscj3010003

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What is the mechanism of the drive-in process in a tube furnace? Master Dopant Redistribution with Nitrogen Shielding

- What are the typical applications for tube furnaces? Master Precise Thermal Processing

- Why is it important to calibrate the temperature profile of a tube furnace? Ensure Accurate and Repeatable Results

- What is the recommended procedure for using a tube furnace after long periods of inactivity? Prevent Damage with Proper Bake-Out

- How does heating zone length impact tube furnace performance? Optimize Uniformity and Capacity

- What industries commonly use horizontal furnaces? Unlock High-Temperature Processing for Your Sector

- Why are tube furnaces considered essential for scientific research? Unlock Precise High-Temperature Control

- How can tube furnaces be enhanced with multiple heating zones and what benefits does this provide? Unlock Precise Temperature Control