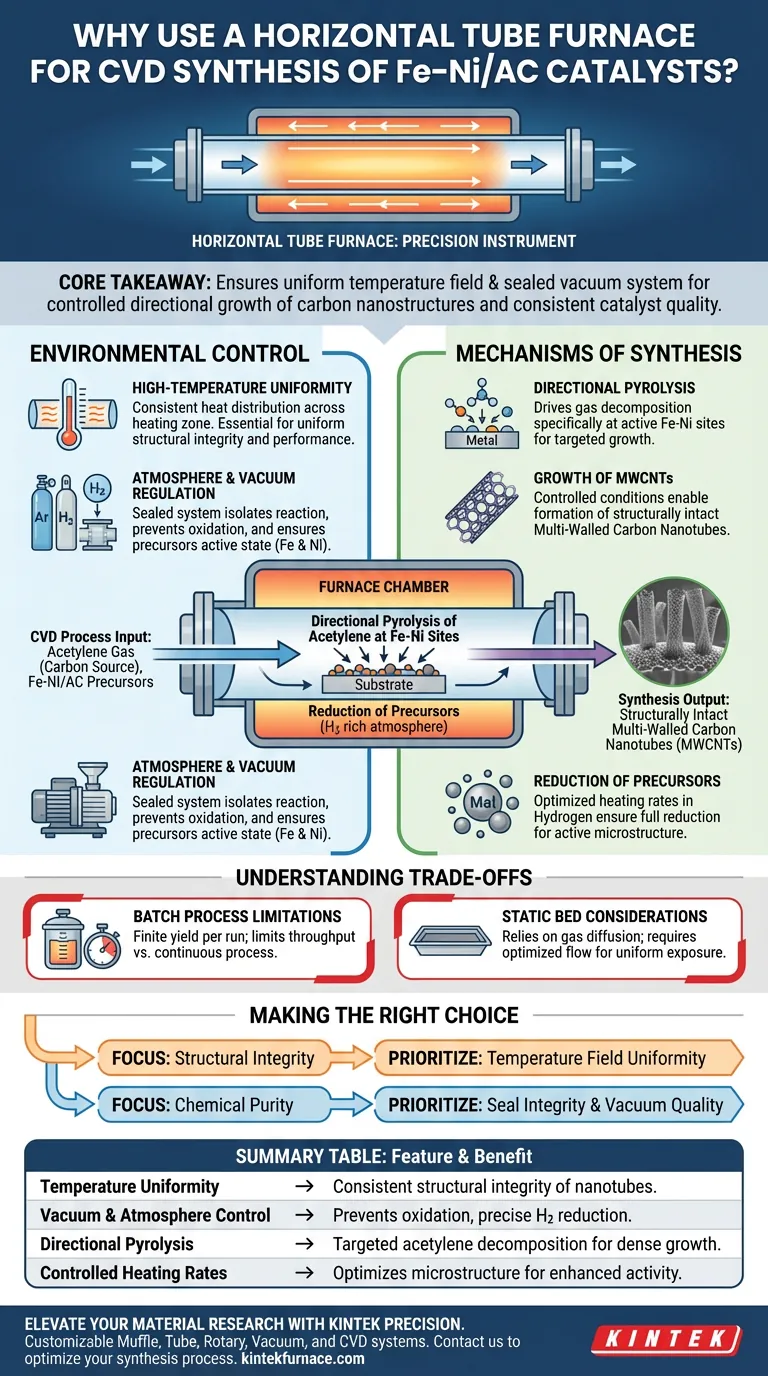

A horizontal tube furnace creates the precise thermal and atmospheric environment necessary for high-quality chemical vapor deposition (CVD). Specifically, for Fe–Ni/AC catalysts, it facilitates the directional pyrolysis of acetylene gas, ensuring the growth of structurally intact multi-walled carbon nanotubes on the substrate.

Core Takeaway The horizontal tube furnace is not merely a heating element; it is a precision instrument that provides a uniform temperature field and a sealed vacuum system. This combination is essential for controlling the directional growth of carbon nanostructures and ensuring consistent catalyst quality across the batch.

The Critical Role of Environmental Control

High-Temperature Field Uniformity

For the synthesis of Fe–Ni/AC catalysts, consistent heat distribution is non-negotiable. The horizontal tube furnace provides a highly uniform temperature field.

This uniformity ensures that the reaction conditions are identical throughout the heating zone. Without this, the structural integrity of the catalyst would vary, leading to inconsistent performance.

Atmosphere and Vacuum Regulation

A defining feature of this equipment is its ability to maintain a sealed vacuum system or a specific gas atmosphere.

In this process, the furnace isolates the reaction from external contaminants. It allows for the introduction of controlled atmospheres, such as inert Argon or reductive Hydrogen mixtures.

This control prevents the oxidation of metal precursors at high temperatures. It ensures that the iron and nickel components remain in the correct active state.

Mechanisms of Catalyst Synthesis

Directional Pyrolysis

The primary function of the furnace during the CVD process is to drive the directional pyrolysis of the carbon source (acetylene gas).

The furnace ensures that the gas decomposes specifically at the Fe–Ni active sites. This targeted reaction is what anchors the growth of the carbon structures to the metal.

Growth of Multi-Walled Carbon Nanotubes

The ultimate goal of this thermal process is the formation of specific nanostructures.

Under these controlled conditions, structurally intact multi-walled carbon nanotubes (MWCNTs) grow on the activated carbon (AC) substrate. The precision of the furnace directly correlates to the quality and density of these nanotubes.

Reduction of Metal Precursors

Before the CVD process, the furnace is often used to reduce metal precursors.

By managing heating rates and dwelling times in a hydrogen-rich atmosphere, the furnace ensures precursors are fully reduced to active metal nanoparticles. This step establishes the necessary microstructure for catalytic activity.

Understanding the Trade-offs

Batch Process Limitations

While horizontal tube furnaces offer exceptional control, they are typically batch reactors.

This limits the throughput compared to continuous industrial processes. For large-scale production, the finite size of the tube dictates the maximum yield per run.

Static Bed Considerations

In a standard horizontal tube furnace, the sample usually sits in a static boat.

Unlike rotary furnaces that tumble particles to ensure even gas exposure, a static setup relies heavily on gas diffusion. This requires careful optimization of flow rates to ensure the acetylene gas reaches all active sites uniformly.

Making the Right Choice for Your Goal

To maximize the effectiveness of a horizontal tube furnace for your specific synthesis needs, consider your primary objective:

- If your primary focus is Structural Integrity: Prioritize the uniformity of the temperature field to ensure the multi-walled carbon nanotubes grow without defects.

- If your primary focus is Chemical Purity: Focus on the seal integrity and vacuum quality to strictly control the reductive atmosphere and prevent precursor oxidation.

Success in synthesizing Fe–Ni/AC catalysts relies on leveraging the furnace's ability to synchronize thermal precision with atmospheric isolation.

Summary Table:

| Feature | Benefit for Fe–Ni/AC Catalyst Synthesis |

|---|---|

| Temperature Uniformity | Ensures consistent structural integrity of carbon nanotubes across the batch. |

| Vacuum & Atmosphere Control | Prevents metal oxidation and allows for precise hydrogen reduction of precursors. |

| Directional Pyrolysis | Facilitates targeted acetylene decomposition at Fe-Ni active sites for dense growth. |

| Controlled Heating Rates | Optimizes the microstructure of metal nanoparticles for enhanced catalytic activity. |

Elevate Your Material Research with KINTEK Precision

High-performance catalyst synthesis demands absolute control over thermal and atmospheric variables. At KINTEK, we specialize in providing cutting-edge solutions for your laboratory needs. Backed by expert R&D and world-class manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems.

Whether you are synthesizing Fe–Ni/AC catalysts or developing next-generation nanomaterials, our high-temperature furnaces are fully customizable to meet your unique research requirements. Partner with us to ensure the structural integrity and chemical purity of your results.

Ready to optimize your synthesis process? Contact our experts today to find the perfect furnace solution for your lab!

Visual Guide

References

- Zohreh Khoshraftar, Alireza Hemmati. Comprehensive investigation of isotherm, RSM, and ANN modeling of CO2 capture by multi-walled carbon nanotube. DOI: 10.1038/s41598-024-55836-6

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What role does a scissor lift play in the thermogravimetric analysis system of a tube furnace? Precision Alignment Guide

- What is the role of high-temperature tube furnaces in the post-processing of graphite oxide nanostructures?

- Why is an atmosphere-controlled tube furnace required for NC substrate preparation? Essential for carbonization.

- How does the strong process performance of vacuum tube furnaces benefit users? Unlock Superior Quality and Efficiency

- What role does a high-temperature tube furnace play in biomass carbonization? Unlock Superior Biochar Structures

- Why is quartz tube vacuum sealing technology utilized during the synthesis of [Pd@Bi10][AlCl4]4 cluster compounds?

- How is a high-temperature tube furnace utilized for biochar activation? Enhance Porosity with CO2 Etching

- What role does sodium hypophosphite (NaH2PO2) play in a tube furnace for NCMCP? Master Precise Phosphidation