In short, the strong process performance of a vacuum tube furnace delivers four primary benefits: superior product quality through precise environmental control, increased efficiency via rapid heating and cooling, long-term reliability from durable materials, and versatility for a wide range of applications. These furnaces excel by creating a highly controlled vacuum or specific gas atmosphere, which is critical for modern material science and production.

The core value of a vacuum tube furnace is not just its ability to get hot, but its power to precisely control the entire thermal process. This control is what prevents contamination, improves material properties, and ultimately delivers a more reliable and repeatable outcome.

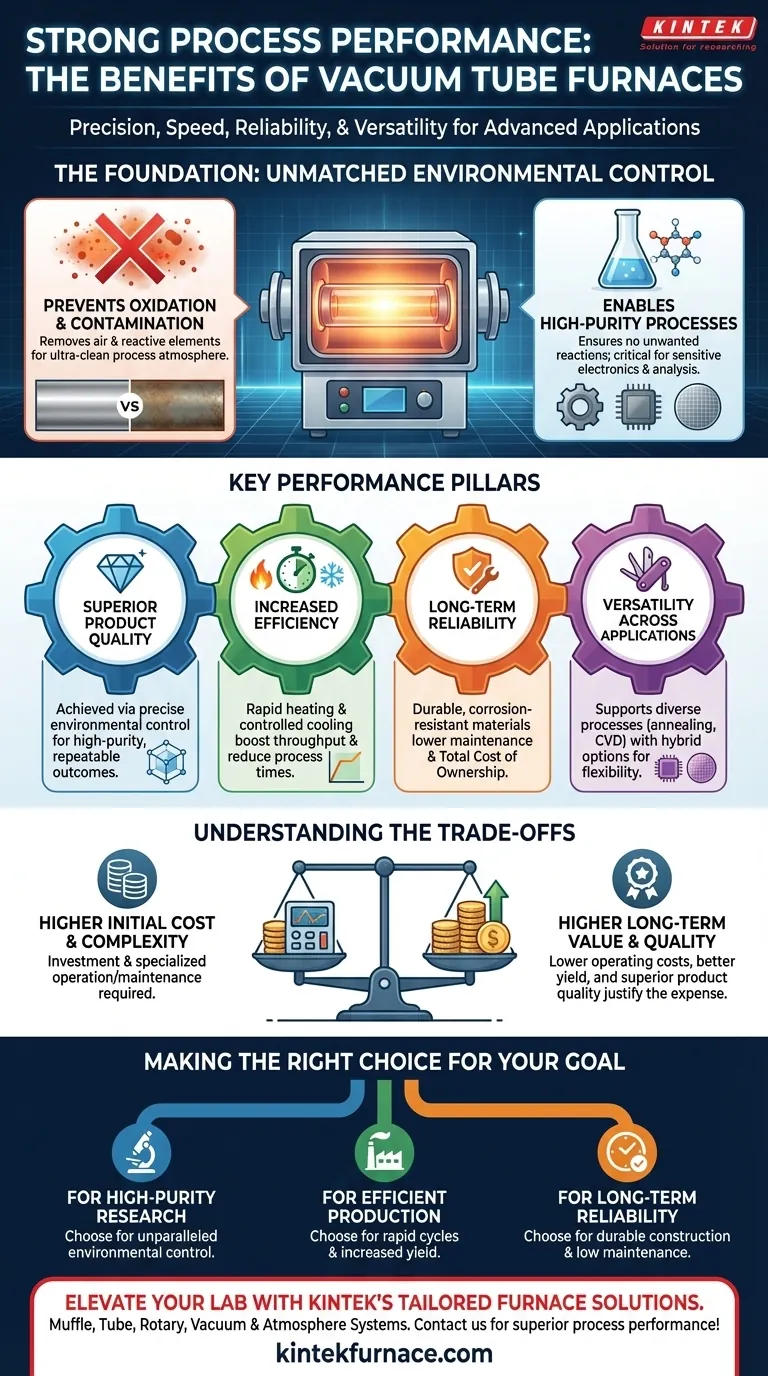

The Foundation: Unmatched Environmental Control

The defining characteristic of a vacuum furnace is its ability to remove the atmosphere—and all the reactive elements within it—from the heating chamber. This single capability is the source of its most significant advantages.

Preventing Oxidation and Contamination

By removing air, particularly oxygen, the furnace prevents oxidation on the surface of the material being heated. The vacuum itself serves as an ultra-clean process atmosphere.

This is essential for processing oxygen-sensitive metals and advanced materials where even minimal surface contamination can compromise the final product's integrity.

Enabling High-Purity Processes

For laboratory research and the manufacturing of sensitive electronics or medical components, purity is paramount.

A vacuum environment ensures that no unwanted chemical reactions occur, allowing for element analysis, annealing, and synthesis with a high degree of precision and repeatability.

Key Performance Pillars Explained

Strong process performance is the result of several integrated design features working together to deliver speed, quality, and reliability.

Rapid Heating and Cooling Cycles

Modern vacuum furnaces are engineered for rapid thermal cycling. Fast heating rates shorten the time it takes to reach the target temperature, directly increasing production throughput.

Equally important, controlled fast cooling capabilities can reduce internal material stress and prevent deformation, which is crucial for maintaining the dimensional accuracy and structural quality of finished parts.

Durability Through Superior Materials

These furnaces are constructed with corrosion-resistant and high-quality materials. This robust build quality is not just for show; it directly enhances the furnace's service life.

A durable furnace means less downtime, lower maintenance costs, and a more reliable production or research schedule, contributing to a lower total cost of ownership.

Versatility Across Applications

The market offers a wide array of models designed for specific tasks, from through-hardening and annealing to chemical vapor deposition.

Furthermore, hybrid furnaces that combine vacuum and atmosphere technologies provide even greater flexibility, allowing users to run a wider variety of processes in a single, efficient piece of equipment.

Understanding the Trade-offs

While powerful, vacuum tube furnaces are not the universal solution for every heating application. Understanding their limitations is key to making an informed decision.

Initial Cost vs. Long-Term Value

Vacuum furnaces typically represent a higher initial capital investment compared to standard atmosphere furnaces. The vacuum pumps, seals, and control systems add complexity and cost.

This initial expense is often justified by higher product quality, increased throughput, and lower long-term operating costs (e.g., no need to purchase expensive process gases).

Maintenance and Operational Complexity

The vacuum system requires specialized knowledge for proper operation and maintenance. Seals must be maintained to prevent leaks, and vacuum pumps require regular service.

This adds a layer of operational complexity that teams must be prepared to handle, unlike simpler, non-vacuum systems.

Making the Right Choice for Your Goal

To determine if a vacuum tube furnace is the right tool, align its capabilities with your primary objective.

- If your primary focus is high-purity research: The unparalleled environmental control is your greatest asset, ensuring uncontaminated and repeatable experimental results.

- If your primary focus is efficient industrial production: The rapid heating/cooling cycles and improved material quality will directly increase your yield and profitability.

- If your primary focus is long-term reliability: The durable construction and reduced reliance on consumable process gases make it a sound investment for consistent, low-maintenance operation.

Ultimately, choosing a vacuum tube furnace is a decision to invest in process control for a superior final product.

Summary Table:

| Benefit | Description |

|---|---|

| Superior Product Quality | Achieved through precise environmental control, preventing oxidation and contamination for high-purity outcomes. |

| Increased Efficiency | Enabled by rapid heating and cooling cycles, boosting throughput and reducing process times. |

| Long-Term Reliability | Resulting from durable, corrosion-resistant materials, lowering maintenance and total cost of ownership. |

| Versatility | Supports diverse applications like annealing and CVD, with hybrid models for added flexibility. |

Ready to elevate your lab's capabilities with advanced high-temperature solutions? KINTEK leverages exceptional R&D and in-house manufacturing to provide diverse laboratories with tailored furnace systems, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs for superior process performance. Contact us today to discuss how we can enhance your research or production efficiency!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab