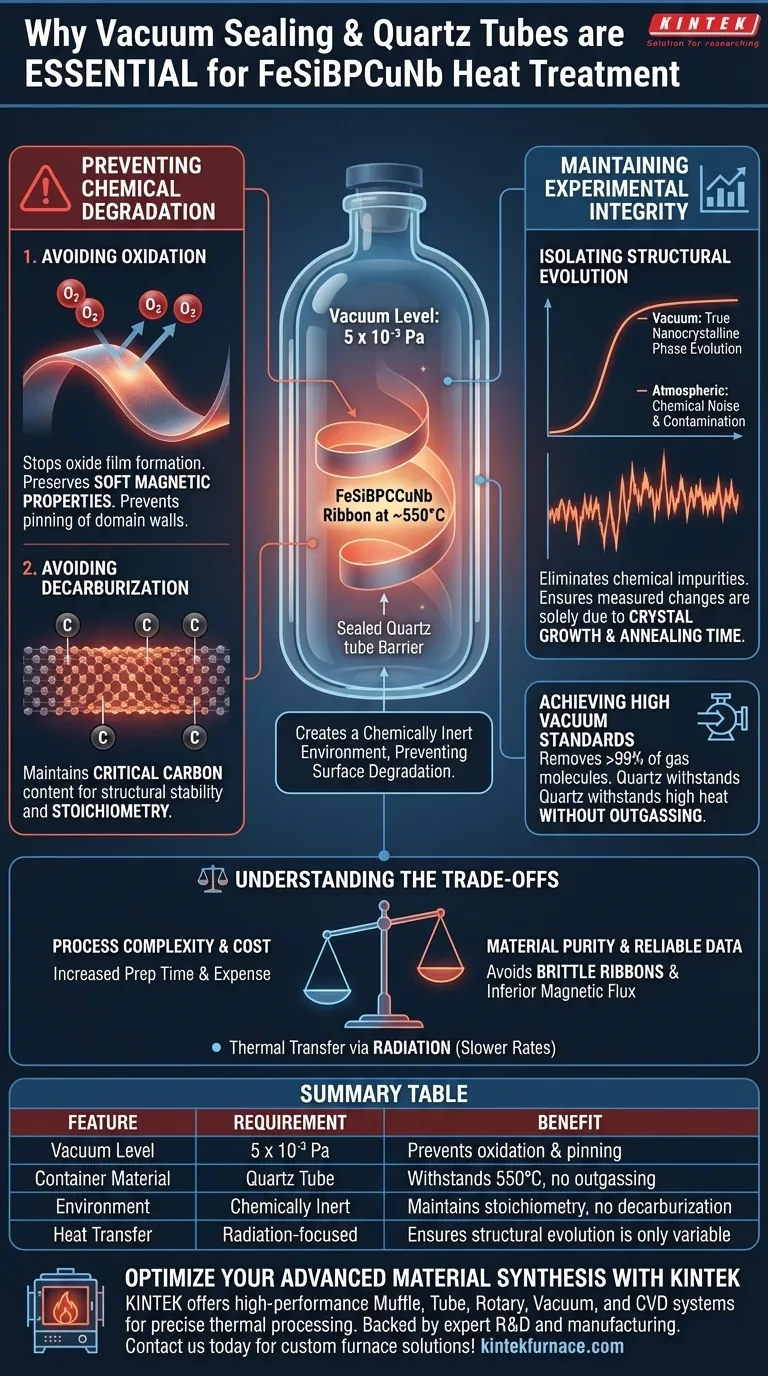

Vacuum sealing techniques and quartz tube containers are essential for the heat treatment of FeSiBPCCuNb amorphous ribbons because they create a chemically inert environment that prevents surface degradation. By achieving a vacuum level of 5 x 10⁻³ Pa, this setup isolates the alloy from atmospheric oxygen and moisture during high-temperature annealing (typically around 550 °C). This protection ensures that the resulting magnetic and structural data reflect the true properties of the material rather than the effects of oxidation or decarburization.

The combination of vacuum sealing and quartz containment acts as a controlled micro-environment, shielding the alloy’s sensitive chemical composition from external interference to ensure repeatable and accurate experimental results.

Preventing Chemical Degradation at High Temperatures

The Risk of Surface Oxidation

At annealing temperatures such as 550 °C, iron-based amorphous ribbons are highly reactive to even trace amounts of oxygen.

Vacuum sealing prevents the formation of oxide films on the ribbon surface, which can act as pinning sites for magnetic domain walls.

If these films are allowed to form, the soft magnetic properties of the FeSiBPCCuNb alloy would be significantly compromised.

Avoiding Decarburization

The presence of carbon in these specific alloys is critical for their structural stability and glass-forming ability.

Exposure to an uncontrolled atmosphere at high heat can lead to decarburization, where carbon is lost from the surface layers of the ribbon.

Quartz tube containers provide a stable, non-reactive vessel that maintains the alloy's stoichiometry throughout the heating and cooling cycles.

Maintaining the Integrity of Experimental Data

Isolating Structural Evolution

The primary goal of heat-treating FeSiBPCCuNb is to study how annealing time affects its nanocrystalline structure.

Without a vacuum, chemical impurities would introduce "noise" into the data, making it impossible to tell if a change in performance is due to crystal growth or chemical contamination.

The inert environment ensures that the evolution of the amorphous-to-nanocrystalline phase remains the only variable being measured.

Achieving High Vacuum Standards

A vacuum level of 5 x 10⁻³ Pa is specifically targeted to provide a high degree of protection.

This level of evacuation removes the vast majority of gas molecules that could collide with and react with the ribbon surface.

Using quartz is vital because it can withstand these high temperatures without outgassing or melting, which would otherwise ruin the vacuum integrity.

Understanding the Trade-offs

Process Complexity vs. Material Purity

Utilizing vacuum sealing and quartz tubes significantly increases the preparation time and cost of each experiment.

While this complexity is a barrier, the trade-off is necessary because atmospheric annealing often results in brittle ribbons with inferior magnetic flux density.

For high-performance alloys like FeSiBPCCuNb, skipping these steps usually leads to data that is unreliable or irreproducible.

Thermal Transfer Limitations

In a vacuum, heat is transferred primarily through radiation rather than convection.

This can lead to slower heating rates or potential thermal gradients across the ribbon samples if not monitored carefully.

Researchers must balance the need for a pure environment with the challenge of ensuring uniform temperature distribution within the quartz tube.

How to Apply This to Your Project

When determining the necessity of vacuum environments for your specific alloy heat treatments, consider your final performance requirements.

- If your primary focus is fundamental research: Always utilize vacuum sealing at 5 x 10⁻³ Pa to ensure your structural analysis is free from chemical interference.

- If your primary focus is optimizing magnetic permeability: Use quartz containment to prevent surface oxide layers that would otherwise impede domain wall motion.

- If your primary focus is industrial scaling: Evaluate whether an inert gas purge (like high-purity Argon) can provide "good enough" protection compared to the higher cost of a full vacuum seal.

Maintaining a rigorous vacuum environment is the only way to ensure that your alloy’s performance is a true reflection of its engineered microstructure.

Summary Table:

| Feature | Requirement/Standard | Benefit for FeSiBPCCuNb |

|---|---|---|

| Vacuum Level | 5 x 10⁻³ Pa | Prevents surface oxidation and domain wall pinning |

| Container Material | Quartz Tube | Withstands high heat (550°C) without outgassing |

| Environment | Chemically Inert | Maintains stoichiometry and prevents decarburization |

| Heat Transfer | Radiation-focused | Ensures structural evolution is the only variable measured |

Optimize Your Advanced Material Synthesis with KINTEK

Precise thermal processing is critical for the evolution of high-performance nanocrystalline structures. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable for your unique research or industrial needs. Whether you are treating Fe-based amorphous ribbons or developing next-gen alloys, our equipment provides the vacuum integrity and temperature uniformity you require.

Ready to elevate your lab's capabilities? Contact us today to find your custom furnace solution!

Visual Guide

References

- Xi Huang, Wenlong Zhu. Effects of Annealing Time on the Structure Characteristics and Magnetic Properties of FeSiBPCCuNb Amorphous Ribbons. DOI: 10.3390/coatings15010050

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How does a tube atmosphere furnace facilitate local CVD during PAN fiber carbonization? Master In-Situ CNT Growth

- What role does a high-temperature tube furnace play in the post-processing of high-entropy alloys? Optimize Microstructure

- What critical conditions does a high-temperature tube furnace provide for LiFePO4/C? Master Precision Calcination

- Why choose a vertical tube furnace over a horizontal tube furnace? Achieve Superior Uniformity and Purity

- Why are high temperature tube furnaces important for industrial and scientific use? Unlock Precision in Material Processing

- What are the benefits of independent temperature control in a three-zone furnace? Enhance Precision and Uniformity

- Why do vacuum tube furnaces require strict pressure control for Borophene synthesis? Master Single-Phase Integrity

- Why is high-purity argon gas essential during the pyrolysis of Cu@Zn-NC in a high-temperature tube furnace?