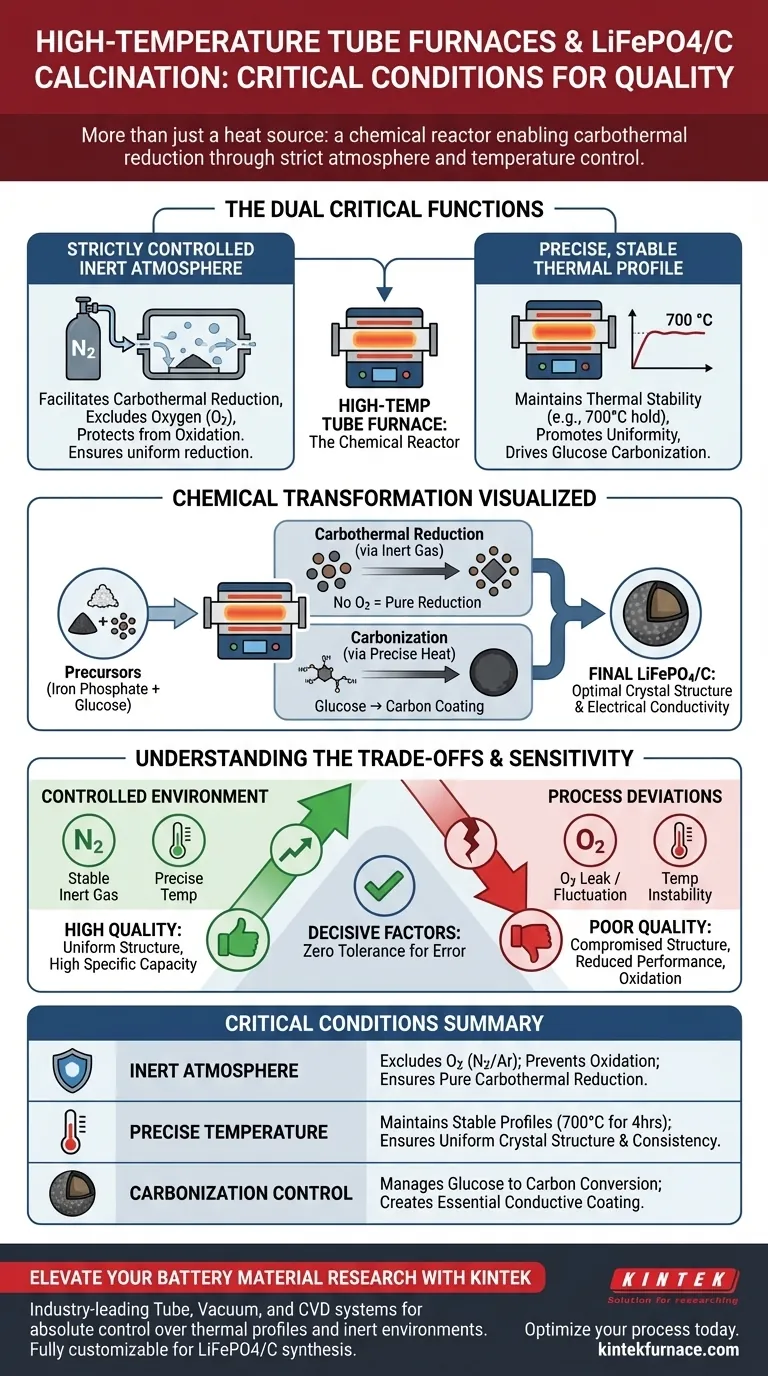

The critical conditions provided by a high-temperature tube furnace for LiFePO4/C calcination are a strictly controlled inert protective atmosphere and a precise, stable thermal profile. By maintaining an oxygen-free environment (typically Nitrogen) and a steady temperature (often 700 °C), the furnace enables the necessary carbothermal reduction reaction that defines the material's final quality.

Core Takeaway The high-temperature tube furnace is not just a heat source; it is a chemical reactor that strictly governs the atmosphere. Its primary function is to synchronize the reduction of iron phosphate with the carbonization of glucose, ensuring the final cathode material possesses both the correct crystal structure and the necessary electrical conductivity.

The Role of Atmosphere Control

Facilitating Carbothermal Reduction

The synthesis of LiFePO4/C relies heavily on a carbothermal reduction reaction. The tube furnace allows for the introduction of a specific inert gas, such as nitrogen.

Protecting the Reaction Environment

This inert atmosphere is strictly controlled to exclude oxygen. This protection ensures that the iron phosphate is uniformly reduced to lithium iron phosphate without unintended oxidation.

Enabling Chemical Transformation

Without this protective gas flow, the chemical transformation required to create the active cathode material would be incomplete or chemically chemically compromised.

The Importance of Precise Temperature Profiles

Maintaining Thermal Stability

The tube furnace provides a precise temperature profile, such as holding the material at exactly 700 °C for a duration of four hours.

Promoting Uniform Reduction

This sustained, high-temperature environment ensures the reduction process is consistent throughout the entire batch. Uniformity is vital for the material's performance consistency.

Creating the Conductive Coating

The heat profile also drives the carbonization of glucose. This process converts the glucose into a conductive carbon coating layer on the particles, which is essential for the electrical performance of the battery material.

Understanding the Trade-offs

Sensitivity to Process Deviations

The conditions within the tube furnace are "decisive factors" for the final product. This means the process has little tolerance for error; any fluctuation in the inert atmosphere or temperature profile directly degrades the material's quality.

Complexity vs. Quality

While maintaining a strictly controlled atmosphere adds complexity compared to open-air calcination, it is non-negotiable for this material. Failing to control the environment results in poor crystal structure and reduced specific capacity.

Making the Right Choice for Your Goal

To optimize the synthesis of LiFePO4/C, you must prioritize the specific parameters of your furnace operation.

- If your primary focus is Crystal Structure: Ensure your furnace creates a strictly inert environment to facilitate a complete and uniform carbothermal reduction.

- If your primary focus is Electrical Conductivity: Prioritize the precision of the thermal profile (e.g., 700 °C hold time) to ensure the glucose effectively carbonizes into a high-quality conductive coating.

The success of your LiFePO4/C synthesis is ultimately determined by how rigorously you control the reduction environment and thermal consistency within the tube furnace.

Summary Table:

| Critical Condition | Function in LiFePO4/C Calcination | Key Benefit |

|---|---|---|

| Inert Atmosphere | Excludes oxygen using Nitrogen or Argon | Prevents oxidation; ensures pure carbothermal reduction |

| Precise Temperature | Maintains stable profiles (e.g., 700°C for 4 hours) | Ensures uniform crystal structure and reaction consistency |

| Carbonization Control | Manages the conversion of glucose to carbon | Creates essential conductive coating for electrical performance |

Elevate Your Battery Material Research with KINTEK

Precision in calcination is the difference between high-performance cathode materials and failed batches. KINTEK provides industry-leading high-temperature Tube, Vacuum, and CVD systems designed to give you absolute control over your thermal profiles and inert environments.

Backed by expert R&D and manufacturing, our systems are fully customizable to meet the rigorous demands of LiFePO4/C synthesis and other advanced lab applications.

Ready to optimize your synthesis process? Contact our experts today to find the perfect furnace solution for your unique laboratory needs.

Visual Guide

References

- Ziyang Xu, Jingkui Qu. Sustainable Utilization of Fe(Ⅲ) Isolated from Laterite Hydrochloric Acid Lixivium via Ultrasonic-Assisted Precipitation to Synthesize LiFePO4/C for Batteries. DOI: 10.3390/ma17020342

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- How do horizontal furnaces contribute to cost savings in industrial processes? Boost Efficiency & Cut Costs

- What role does a dual-zone tube furnace play in the synthesis of large-scale Janus RhSeCl single crystals?

- How does a high-temperature tube furnace facilitate sulfur melt-diffusion? Precision Heating for PCFC/S Cathodes

- Why is a high-temperature tube furnace used for SNCB preparation? Optimize Nitrogen-Doped Porous Carbon Synthesis

- What are the main components of a 70mm tube furnace? Uncover Key Parts for Precise Thermal Processing

- How does a high-precision horizontal tube furnace facilitate the activation stage of catalysts? Optimize Pore Integrity

- What are the disadvantages of a tube furnace? Key Limitations for Industrial and Lab Use

- What role does a high-temperature tube furnace play in the solid-state synthesis of LIB cathode materials? Key Insights