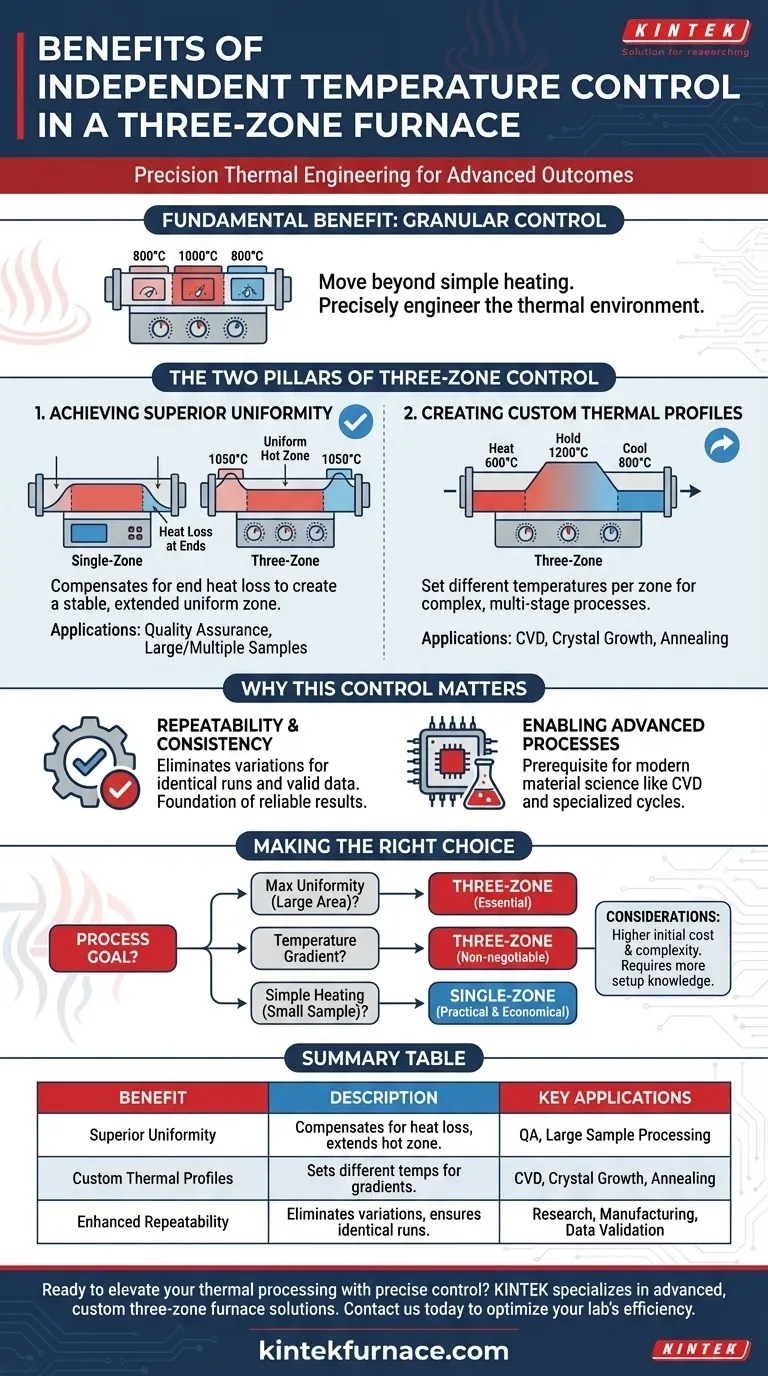

The fundamental benefit is granular control. Independent temperature control in a three-zone furnace allows you to move beyond simple heating and precisely engineer the thermal environment. This capability enables you to either create an exceptionally uniform temperature across a long area or establish a specific temperature gradient, unlocking more advanced and repeatable process outcomes.

A three-zone furnace provides control over the entire thermal profile. This can be leveraged in two distinct ways: to counteract natural heat loss at the ends for superior temperature uniformity, or to intentionally create different temperature zones for complex processes.

The Two Pillars of Three-Zone Control

The advantage of a three-zone furnace is not singular; it offers two primary benefits that cater to different scientific and industrial needs. Understanding both is key to determining if it's the right tool for your work.

Benefit 1: Achieving Superior Temperature Uniformity

In any furnace, heat naturally escapes from the ends. A single-zone furnace is only truly uniform in its very center, with temperatures dropping off toward the edges.

A three-zone furnace directly solves this problem. By setting the two end zones to a slightly higher temperature, you can create a thermal "guard" that compensates for this heat loss.

The result is a significantly longer and more stable uniform hot zone along the furnace's length. This is critical for processes where multiple samples or a single large sample must experience the exact same temperature.

Benefit 2: Creating Custom Thermal Profiles

The more intuitive benefit is the ability to set each zone to a completely different temperature on purpose. This creates a specific temperature gradient.

This flexibility is essential for complex, multi-stage thermal processes that occur within a single run.

For example, a material might need to be heated, held at a peak temperature, and then cooled in a controlled manner. A three-zone furnace can be programmed to execute this entire profile as the sample moves through it or as the program progresses over time.

Why This Control Matters for Your Process

Precise thermal management is not just a feature; it directly impacts the quality, consistency, and capability of your work.

Ensuring Repeatability and Consistency

By eliminating temperature variations as a source of error, you ensure that every run is identical to the last. This is the foundation of repeatable results.

This level of control is crucial for quality assurance in manufacturing and for producing valid data in research environments. Consistent thermal processing leads to consistent material properties and outcomes.

Enabling Advanced Processes

Many modern material science and chemical processes are impossible without gradient control.

Applications like chemical vapor deposition (CVD), certain types of crystal growth, annealing, and specialized stress relief cycles rely on maintaining different temperatures at different points in the process chamber. A three-zone furnace is a prerequisite for this work.

Understanding the Trade-offs

While powerful, a three-zone furnace is not always the necessary choice. Understanding its complexities and costs is crucial for making an objective decision.

Increased Complexity and Cost

A three-zone system has more heating elements, more thermocouples for measurement, and more sophisticated controllers. This inherently increases the initial purchase price.

This complexity also extends to operation. Programming and optimizing a three-zone profile requires more knowledge and setup time compared to a simple, single-zone furnace.

When a Single-Zone is Sufficient

If your application only requires heating a small sample in the center of the furnace, the natural uniform zone of a single-zone model is often adequate.

For simple processes without a need for extended uniformity or temperature gradients, the added expense and complexity of a three-zone furnace may not be justified.

Making the Right Choice for Your Application

Your specific process goal is the ultimate determining factor.

- If your primary focus is maximum temperature uniformity over a large area: A three-zone furnace is essential to compensate for end losses and extend the flat hot zone.

- If your primary focus is a process requiring a temperature gradient (e.g., CVD): Independent zone control is a non-negotiable requirement, making a three-zone furnace the only option.

- If your primary focus is simple, cost-effective heating of small samples: A single-zone furnace is likely the most practical and economical solution.

Ultimately, choosing a three-zone furnace is an investment in process control, repeatability, and the flexibility to execute more demanding thermal applications.

Summary Table:

| Benefit | Description | Key Applications |

|---|---|---|

| Superior Temperature Uniformity | Compensates for heat loss at ends, creating a stable, extended uniform hot zone. | Quality assurance, large sample processing, consistent material properties. |

| Custom Thermal Profiles | Allows setting different temperatures per zone to create specific gradients for multi-stage processes. | Chemical vapor deposition (CVD), crystal growth, annealing, stress relief cycles. |

| Enhanced Repeatability and Consistency | Eliminates temperature variations, ensuring identical results across runs. | Research, manufacturing, data validation, material science experiments. |

Ready to elevate your thermal processing with precise control? KINTEK specializes in advanced high-temperature furnace solutions, including custom three-zone designs. Leveraging our exceptional R&D and in-house manufacturing, we offer products like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure we meet your unique experimental needs for superior uniformity and gradient control. Contact us today to discuss how we can optimize your lab's efficiency and outcomes!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety