At its core, a 70mm tube furnace is a high-temperature device designed to create a precisely controlled thermal environment. Its key characteristics are a uniform central heating zone, the ability to manage the internal atmosphere (from inert gas to vacuum), and a 70mm inner tube diameter that dictates its sample capacity. This combination makes it a versatile tool for heating materials in research and small-scale production.

A 70mm tube furnace is more than just an oven; it is a controlled-environment reactor. Understanding its capabilities and limitations is critical to moving from simple heating to precise material transformation. The 70mm size strikes a deliberate balance between sample volume and operational efficiency.

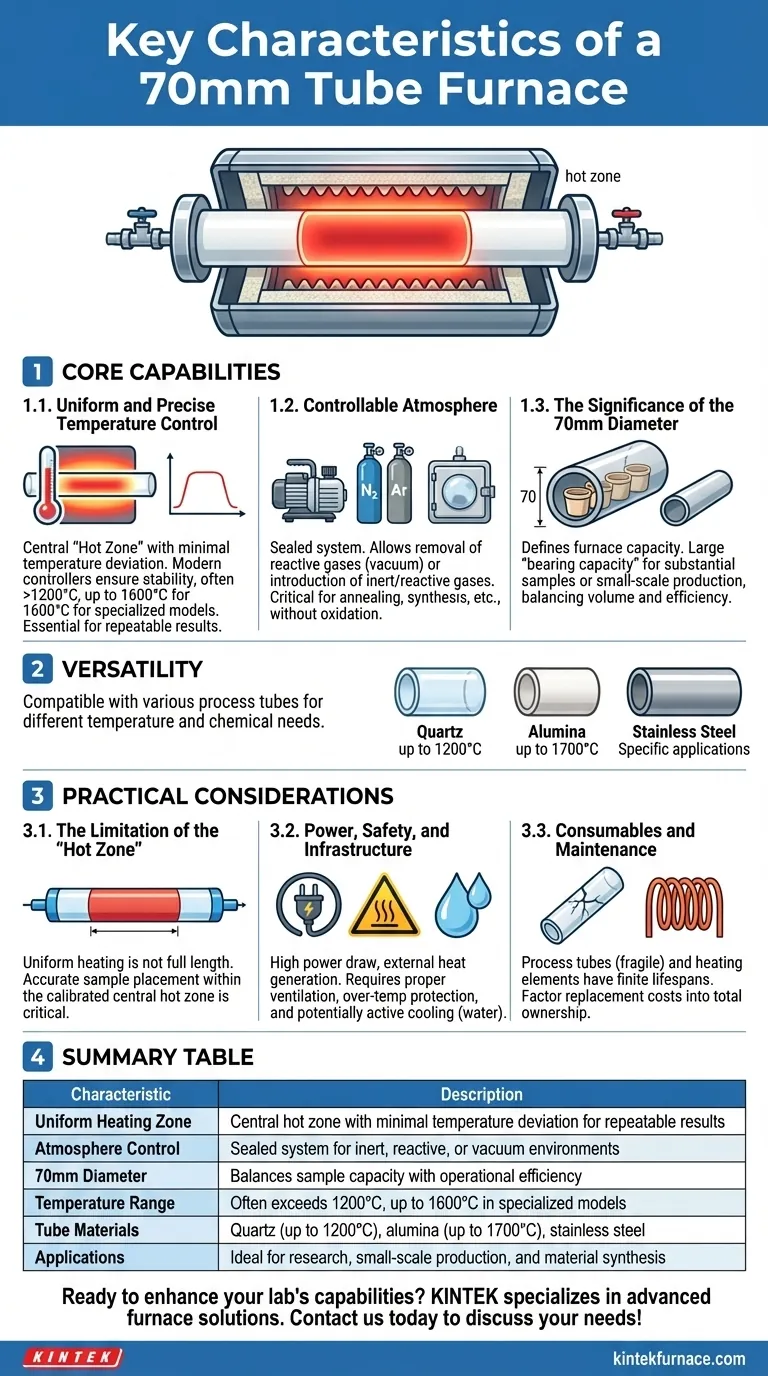

Deconstructing the Core Capabilities

A tube furnace's value comes from its ability to isolate and precisely control the conditions applied to a sample. The "70mm" designation simply defines the size of that controlled environment.

Uniform and Precise Temperature Control

The primary function is to deliver stable, uniform heat. Furnaces are engineered to create a "hot zone" in the center of the tube, where temperature deviation is minimal.

While the ends of the tube will naturally be cooler, modern temperature controllers ensure the central zone remains precisely at the setpoint, often with capabilities exceeding 1200°C and even reaching 1600°C in specialized models. This uniformity is essential for achieving repeatable experimental results.

Controllable Atmosphere

Unlike a conventional oven, a tube furnace is a sealed system. This allows you to control the gaseous atmosphere surrounding your sample.

By connecting gas lines and a vacuum pump, you can remove reactive gases like oxygen and introduce inert gases (like argon or nitrogen) or reactive gases. This is critical for processes like annealing or material synthesis, where oxidation would compromise the outcome.

The Significance of the 70mm Diameter

The 70mm inner diameter is a key specification that defines the furnace's capacity. It is large enough to accommodate substantial samples, multiple smaller crucibles, or small-scale production runs.

This size represents a common midpoint, offering a larger "bearing capacity" than smaller lab-scale furnaces without the massive power and infrastructure requirements of a full-scale industrial furnace.

Versatility in Configuration and Materials

Most 70mm tube furnaces are horizontal, which simplifies sample loading and unloading. A crucial feature is their compatibility with various process tubes.

The choice of tube material is dictated by your temperature and chemical needs:

- Quartz: Common for temperatures up to 1100-1200°C.

- Alumina: Required for higher temperatures (up to 1700°C) and offers good chemical resistance.

- Stainless Steel: Used in specific applications where metallic properties or durability are needed.

Understanding the Trade-offs and Practical Considerations

While powerful, tube furnaces have operational realities that must be managed for successful and safe use.

The Limitation of the "Hot Zone"

The specified uniform heating zone is not the full length of the furnace tube. The temperature naturally drops off toward the ends of the tube.

Accurate sample placement is therefore critical. You must position your materials entirely within the calibrated central hot zone to ensure they experience the intended thermal profile.

Power, Safety, and Infrastructure

High-temperature models draw significant power and may require specialized electrical circuits. They also generate a great deal of external heat.

Safety features like over-temperature protection and door interlocks are standard, but proper facility ventilation is essential. Some high-temperature or continuous-use applications may also require an active cooling system, often using water.

Consumables and Maintenance

Process tubes, especially quartz, are fragile and should be considered consumables. They can crack from thermal shock or mishandling.

Heating elements also have a finite lifespan and will eventually need replacement. Factoring in the cost of these replacement parts is part of the total cost of ownership.

Making the Right Choice for Your Goal

Selecting the correct configuration depends entirely on your specific application.

- If your primary focus is repeatable lab-scale experiments: A 70mm furnace provides a highly controlled atmosphere and a reliable uniform heat zone crucial for generating high-quality, reproducible data.

- If your primary focus is processing larger samples or pilot production: The 70mm diameter offers a significant step up in volume and capacity compared to smaller, purely analytical furnaces.

- If your primary focus is extreme high-temperature work (>1200°C): You must specify a furnace with appropriate heating elements (e.g., MoSi2) and use a high-purity alumina tube, while also confirming your facility has the necessary power and cooling.

By understanding these characteristics, you can leverage the tube furnace as a precise instrument for material transformation, not just a simple heater.

Summary Table:

| Characteristic | Description |

|---|---|

| Uniform Heating Zone | Central hot zone with minimal temperature deviation for repeatable results |

| Atmosphere Control | Sealed system for inert, reactive, or vacuum environments |

| 70mm Diameter | Balances sample capacity with operational efficiency |

| Temperature Range | Often exceeds 1200°C, up to 1600°C in specialized models |

| Tube Materials | Quartz (up to 1200°C), alumina (up to 1700°C), stainless steel |

| Applications | Ideal for research, small-scale production, and material synthesis |

Ready to enhance your lab's capabilities with a high-temperature furnace? KINTEK specializes in advanced solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With our strong R&D and in-house manufacturing, we offer deep customization to meet your unique experimental needs. Contact us today to discuss how our 70mm tube furnaces can deliver precise temperature control, atmosphere management, and reliable performance for your research or production goals!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability