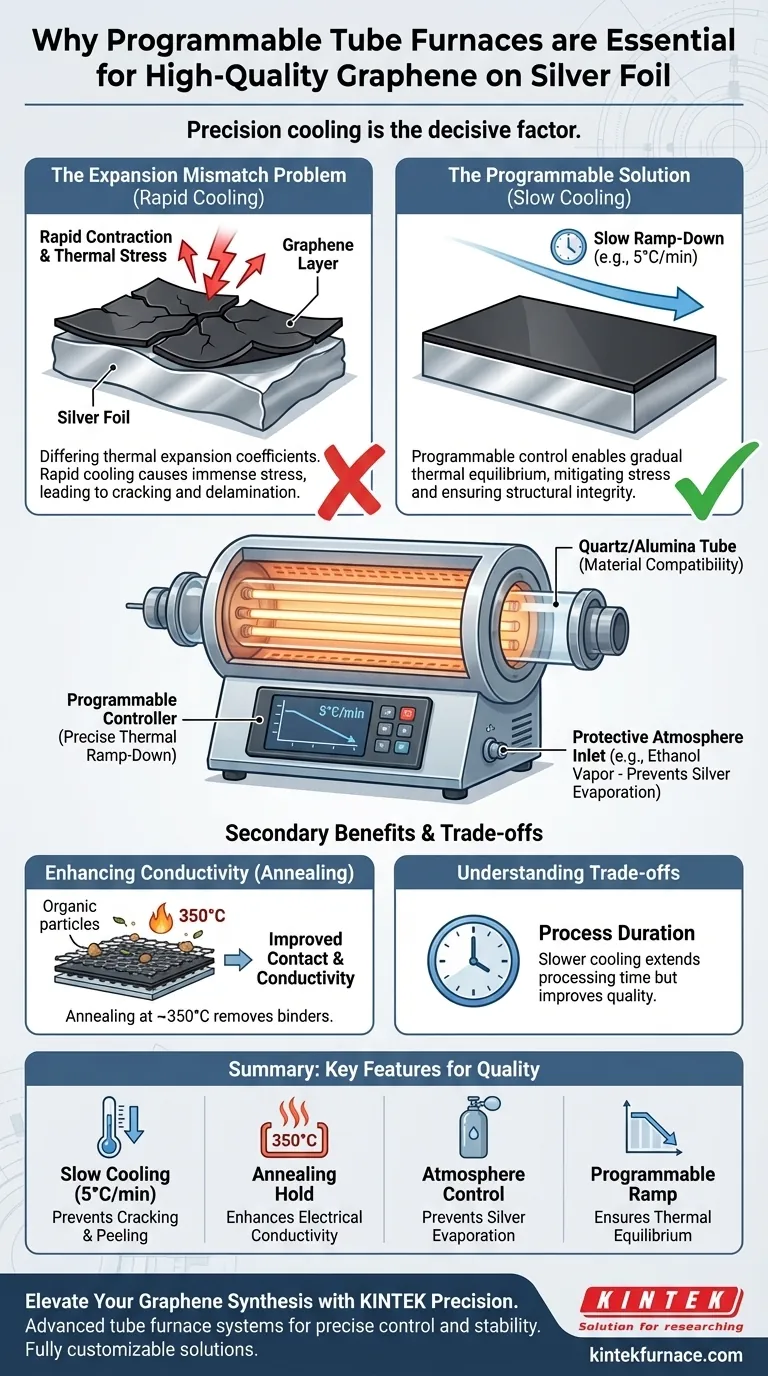

Precision cooling is the decisive factor in graphene quality. A tube furnace with programmable temperature control is necessary because it enables the execution of specific slow-cooling strategies, such as a rate of 5°C per minute. Without this controlled thermal descent, the significant difference in thermal expansion between the silver foil and the graphene layer would cause the coating to crack, peel, or delaminate during the cooling phase.

Core Takeaway High-quality graphene production relies on managing the mismatch in thermal expansion coefficients between the substrate and the coating. Programmable furnaces provide the precise thermal ramp-down required to mitigate stress, ensuring the graphene layer maintains its structural integrity and adhesion to the silver foil.

The Mechanics of Thermal Stress

The Expansion Mismatch

Silver and graphene possess vastly different thermal expansion coefficients. As the materials are heated and subsequently cooled, they expand and contract at different rates.

The Risk of Rapid Cooling

If the sample is cooled too quickly—as would happen in a non-programmable furnace—the silver substrate contracts much faster than the graphene layer.

This rapid contraction generates immense thermal stress at the interface between the two materials. This stress physically tears the graphene, leading to cracking or complete detachment from the foil.

How Programmable Control Solves the Problem

Implementing Slow-Cooling Strategies

Programmable controllers allow researchers to define an exact cooling curve. By setting a slow ramp-down rate, specifically around 5°C per minute, the furnace ensures that both materials cool gradually.

Mitigating Structural Failure

This gradual process allows the materials to reach thermal equilibrium continuously. It minimizes the instantaneous stress on the interface, preventing the graphene from fracturing.

Atmosphere Management

The tube furnace design allows for a continuous supply of a protective atmosphere, such as ethanol vapor. This is critical during the cooling phase to prevent the evaporation of silver, which can further destabilize the graphene layer.

Secondary Benefits of the Tube Furnace

Enhancing Conductivity through Annealing

Beyond stress management, the precise heating capabilities of the furnace facilitate effective annealing (often around 350°C). This process carbonizes residual binders and removes excess organic components.

Improving Contact

This removal of impurities enhances the contact between graphene layers. The result is significantly improved macroscopic electrical conductivity and better structural stability.

Understanding the Trade-offs

Process Duration

The primary trade-off of using programmable slow cooling is time. Strategies requiring 5°C/minute ramp-downs significantly extend the total processing time compared to rapid-cooling methods, reducing throughput.

Material Compatibility

While tube furnaces offer versatility, one must carefully select the tube material (e.g., quartz vs. alumina). Incorrect selection can lead to adverse chemical reactions between the furnace tube and the sample at high temperatures, contaminating the graphene.

Making the Right Choice for Your Goal

To maximize the quality of your graphene-on-silver synthesis, consider the following:

- If your primary focus is Structural Integrity: Prioritize a programmable cooling rate of 5°C/min to prevent thermal stress fractures.

- If your primary focus is Electrical Conductivity: Ensure your profile includes an annealing hold (e.g., 350°C) to fully decompose organic binders and improve layer contact.

- If your primary focus is Purity: Verify that your furnace tube material (Quartz or Alumina) is chemically inert relative to your specific silver and carbon precursors.

Control the cooling rate, and you control the structural destiny of your material.

Summary Table:

| Feature | Purpose in Graphene Synthesis | Benefit to Material Quality |

|---|---|---|

| Slow Cooling (5°C/min) | Manages thermal expansion mismatch | Prevents cracking, peeling, and delamination |

| Annealing (350°C) | Carbonizes binders and removes organics | Enhances macroscopic electrical conductivity |

| Atmosphere Control | Provides protective ethanol vapor | Prevents silver evaporation and destabilization |

| Programmable Ramp | Ensures thermal equilibrium | Minimizes interface stress for structural integrity |

Elevate Your Graphene Synthesis with KINTEK Precision

Don’t let thermal stress compromise your material research. KINTEK’s advanced tube furnace systems provide the precise programmable temperature control and atmospheric stability required for high-quality graphene production.

Backed by expert R&D and manufacturing, we offer a comprehensive range of Tube, Muffle, Rotary, Vacuum, and CVD systems—all fully customizable to meet your laboratory's unique high-temperature requirements.

Ready to optimize your thermal profiles? Contact KINTEK today to find your perfect furnace solution!

Visual Guide

References

- Hikaru Iwatani, Fumihiko Maeda. Graphene Synthesis on Silver Foil by Chemical Vapor Deposition Using Ethanol. DOI: 10.1380/ejssnt.2025-026

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is a Tube Furnace? Master Precision Heating for Sensitive Materials

- What is the function of a phosphorus diffusion tube furnace? Creating MoS2/Si Heterojunctions with Precision

- How does a split tube furnace compare to non-split tube furnaces? Choose the Right Furnace for Your Lab

- What are the different types of tube furnaces and their features? Choose the Right Furnace for Your Lab

- What are the components of a basic tube furnace design capable of withstanding 1200°C? Essential Parts for High-Temp Labs

- Why is the chemical composition of the alloy used in tube reactors critical? Insights into Ethane Cracking Results

- At what pressures can gases be introduced into the 3-Zone tube furnace? Optimize Your Thermal Process Control

- Why is a tube furnace required during the synthesis of phosphorus-doped nickel catalysts using high-purity nitrogen?