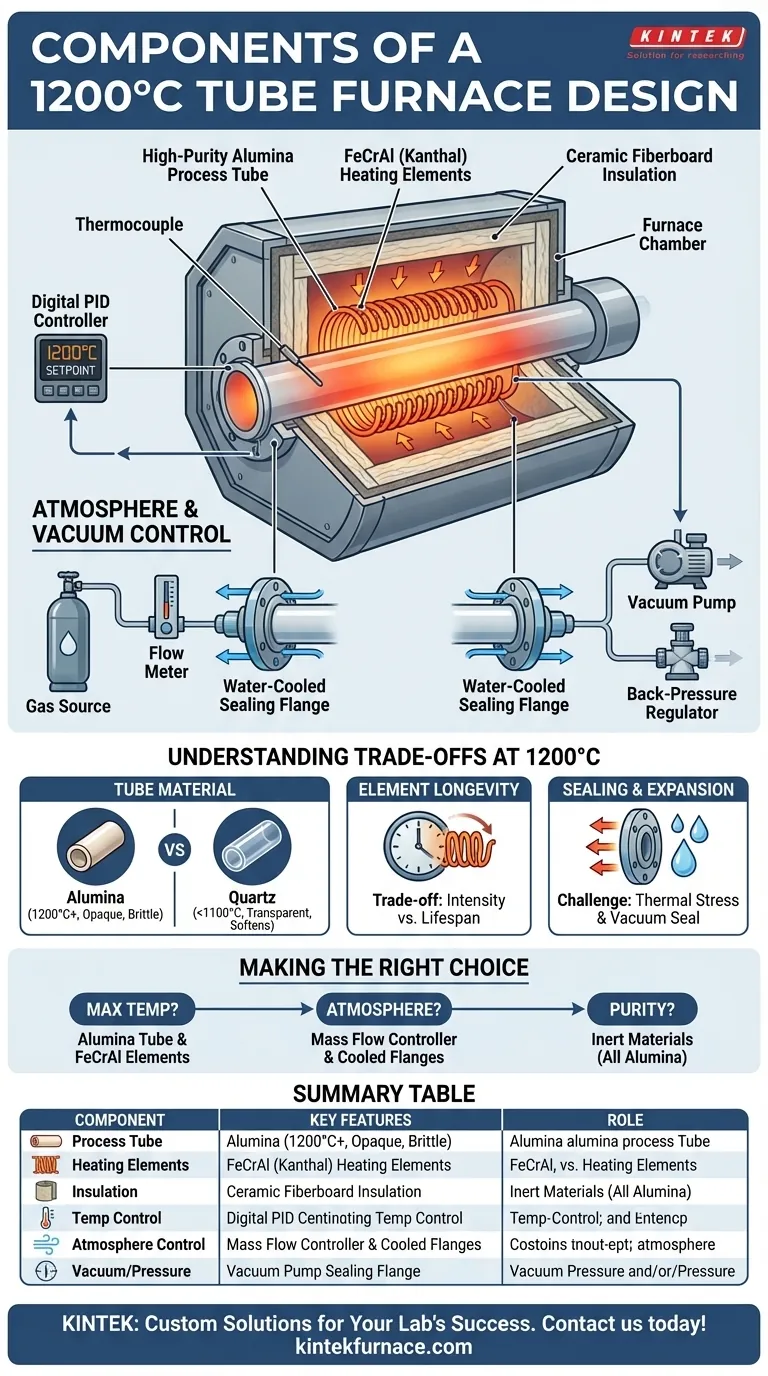

At its core, a tube furnace capable of 1200°C is built from a few fundamental components. The design centers on heating elements, typically high-resistance coils, wrapped around a ceramic process tube. This assembly is housed within a thermally insulated chamber, with a thermocouple providing temperature feedback to a controller to maintain the setpoint accurately.

A functional 1200°C tube furnace is not just a heating chamber; it's an integrated system. The choice of process tube material, heating elements, and control systems must work in concert to ensure uniform temperature, a controlled atmosphere, and operational safety.

Deconstructing the Core Furnace Body

The physical structure of the furnace is designed for two purposes: generating intense heat and containing it safely and efficiently. Each component is selected to withstand extreme thermal stress.

The Furnace Chamber and Insulation

The outer body or chamber provides structural support for all other components.

It is filled with high-grade thermal insulation, often a rigid ceramic fiberboard. This insulation is critical for minimizing heat loss, ensuring temperature stability, and keeping the external surface safe to touch.

The Heating Elements

Heating is achieved using high-resistance wire, frequently a FeCrAl (Kanthal) alloy, which is coiled and embedded around the process tube.

These elements are chosen for their ability to operate continuously at temperatures exceeding 1200°C without rapid degradation. Their placement is engineered to provide uniform heat distribution along the length of the tube.

The Process Tube

This is the central component where the sample or process occurs. The material of this tube is arguably the most critical choice for a high-temperature furnace.

For sustained 1200°C operation, a high-purity alumina ceramic tube is the standard. It offers excellent thermal stability and chemical resistance at these temperatures.

Critical Control and Monitoring Systems

Simply generating heat is not enough. A furnace must precisely control the temperature and, in most cases, the atmosphere within the process tube.

The Temperature Control System

This is a closed-loop system. A thermocouple, a sensor designed for high temperatures, is placed near the process tube to measure its actual temperature.

This measurement is sent to a digital PID controller, which then modulates the power sent to the heating elements. This constant feedback loop allows the furnace to maintain a stable setpoint with high accuracy.

Atmosphere Control Components

Most applications require a controlled gas environment. This is managed by a gas circulation system.

Components include a gas source, flow lines with valves, and a flow meter (ranging from a simple ball-type to a precise digital mass flow controller).

To maintain this atmosphere, sealing flanges or masks are used on the ends of the tube. These are often made of aluminum and may incorporate water-cooling channels to protect their silicone O-ring seals from the extreme heat.

Vacuum and Pressure Systems

For applications requiring a vacuum, a vacuum pump is connected to one of the sealing flanges.

Conversely, a back-pressure regulator can be used on the outlet to maintain a positive pressure environment within the tube.

Understanding the Trade-offs at 1200°C

Operating at high temperatures introduces significant material science and engineering challenges. Your component choices involve clear trade-offs between performance, longevity, and cost.

Alumina vs. Quartz Tubes

Quartz tubes are transparent, allowing for visual monitoring of a process. However, their softening point is near 1100°C, making them unsuitable and unsafe for sustained operation at 1200°C.

Alumina tubes are opaque but are the correct choice for 1200°C and above. They are more brittle and susceptible to thermal shock if heated or cooled too rapidly, but their high-temperature structural integrity is essential.

Heating Element Longevity

Even robust FeCrAl elements will degrade over time with repeated, prolonged use at maximum temperature. This is a consumable part of the furnace, and its lifespan is a direct trade-off with operating intensity.

Sealing and Thermal Expansion

Creating a perfect, vacuum-tight seal at the ends of a 1200°C tube is difficult. The tube expands significantly with heat, putting stress on any sealing mechanism. This is why water-cooled flanges are often necessary to keep the sealing O-rings at a safe operating temperature.

Making the Right Choice for Your Application

Your specific experimental goal will dictate which components you should prioritize.

- If your primary focus is reaching maximum temperature reliably: Prioritize a high-purity alumina tube and robust FeCrAl (Kanthal) heating elements.

- If your primary focus is precise atmosphere control: Invest in a high-quality mass flow controller and vacuum-tight, water-cooled sealing flanges.

- If your primary focus is process purity: Ensure all wetted parts, including the tube and any internal fixtures, are made of inert materials like high-purity alumina.

By understanding how these components interact, you can confidently specify a system that delivers reliable and precise high-temperature performance.

Summary Table:

| Component | Key Features | Role in 1200°C Operation |

|---|---|---|

| Process Tube | High-purity alumina ceramic | Withstands high temperatures, provides chemical resistance |

| Heating Elements | FeCrAl (Kanthal) alloy coils | Generates and distributes heat uniformly up to 1200°C |

| Insulation | Ceramic fiberboard | Minimizes heat loss, ensures safety and stability |

| Temperature Control | Thermocouple and PID controller | Maintains precise temperature via feedback loop |

| Atmosphere Control | Gas flow meters, sealing flanges | Manages gas environment, often with water-cooling |

| Vacuum/Pressure Systems | Vacuum pump, back-pressure regulator | Enables vacuum or positive pressure conditions |

Ready to build a custom tube furnace for your high-temperature needs? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure your furnace precisely meets unique experimental requirements, enhancing efficiency and reliability. Contact us today to discuss how we can support your lab's success!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety