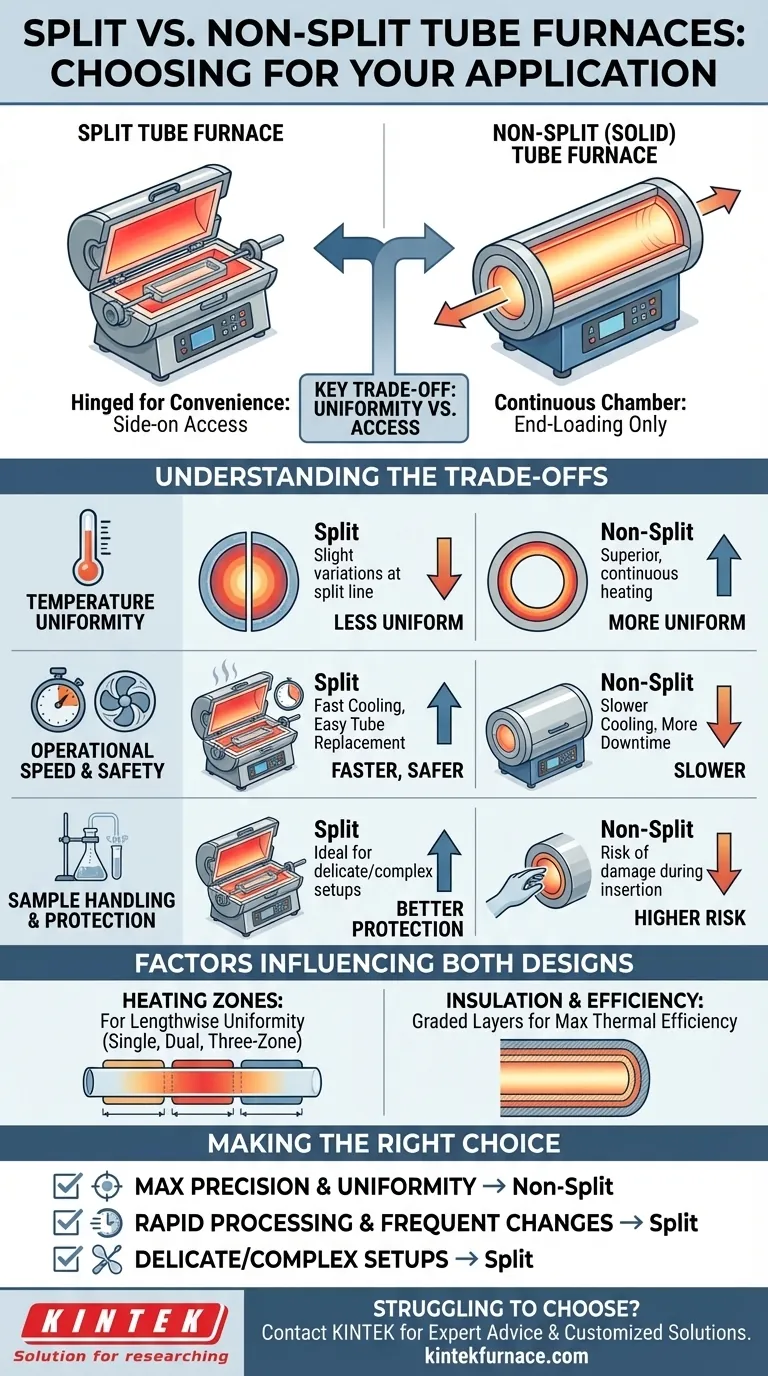

The fundamental difference between a split tube furnace and a non-split (or solid) tube furnace is physical access. A split tube furnace is built in two halves and hinges open, allowing direct, side-on access to the internal work tube. In contrast, a non-split furnace is a single, solid cylinder, requiring samples and equipment to be loaded and unloaded from the ends.

Your choice is not about which furnace is universally "better," but about a critical trade-off: Non-split furnaces offer superior temperature uniformity, while split tube furnaces provide unmatched operational convenience and sample protection.

The Core Design Difference: Access

The primary distinction dictates how you interact with the furnace and your sample during every stage of your process.

Split Tube Furnaces: Hinged for Convenience

A split tube furnace consists of semi-cylindrical heating elements that can be opened along a hinge. This design provides direct, open access to the chamber.

This is especially valuable when working with large, delicate, or complex experimental setups that cannot be easily slid into a tube from the end without risk of damage.

Non-Split (Solid) Tube Furnaces: A Continuous Chamber

A non-split furnace features a continuous, solid heating chamber. Access is limited to the two ends of the process tube, which typically protrude from the furnace body.

This simpler design is robust but requires careful insertion and removal of all materials through the tube's opening.

Understanding the Key Trade-offs

The design difference in access creates a series of important performance and operational trade-offs you must consider for your specific application.

Temperature Uniformity: The Non-Split Advantage

The primary advantage of a non-split furnace is its potential for more uniform temperature distribution. The continuous ring of heating elements provides more even heating, especially across the cross-section of the tube.

Split tube furnaces, which often have top and bottom heating elements, can have slight temperature variations at the split line. While well-designed models minimize this, a solid tube design is inherently more uniform.

Operational Speed & Safety: The Split Tube Advantage

Split tube furnaces excel in processes requiring rapid cooling. By simply opening the furnace body, the work tube and sample are exposed to ambient air, allowing for a much faster temperature drop than waiting for a solid furnace to cool down naturally.

This design also makes replacing a work tube significantly easier and faster, reducing downtime.

Sample Handling & Protection: The Split Tube Advantage

For experiments involving fixed catalysts, in-situ probes, or irregularly shaped samples, the side-access of a split tube furnace is invaluable.

It minimizes the risk of disturbing or damaging a carefully prepared setup during insertion or removal, a common challenge with the end-loading required by non-split furnaces.

Factors That Influence Both Designs

While the split vs. non-split decision is central, other features are common to both types and also impact performance.

Heating Zones for Lengthwise Uniformity

Both furnace types can be configured with single, dual, or three heating zones. A three-zone furnace uses independent controllers for the center and end zones to create an exceptionally uniform temperature profile along the length of the tube.

This feature can compensate for heat loss at the ends and is crucial for processes requiring consistent temperature over a long area, regardless of furnace type.

Insulation and Efficiency

Modern furnaces, both split and non-split, use graded layers of high-quality insulation and insulating vestibules at the tube ends. These features are designed to maximize thermal efficiency and minimize heat loss to the surrounding environment.

Broader Furnace Classifications

The "split" vs. "non-split" characteristic is just one aspect of a furnace. This choice can be combined with other classifications, such as horizontal or vertical orientation, and compatibility with vacuum or specific atmospheric conditions.

Making the Right Choice for Your Application

Selecting the correct furnace requires aligning the equipment's strengths with your primary experimental needs.

- If your primary focus is maximum temperature precision and uniformity: A non-split (solid) tube furnace is the superior choice, as its continuous heating chamber provides the most even heat distribution.

- If your primary focus is rapid processing and frequent sample changes: A split tube furnace offers significant advantages with its fast cooling capabilities and easy tube access.

- If you work with large, delicate, or complex in-tube setups: The side-access of a split tube furnace is critical for protecting your sample and equipment during loading and unloading.

Ultimately, understanding this core trade-off between uniformity and access empowers you to select the furnace that directly serves your experimental goals.

Summary Table:

| Feature | Split Tube Furnace | Non-Split Tube Furnace |

|---|---|---|

| Access | Side-on via hinged halves | End-loading only |

| Temperature Uniformity | Slight variations at split line | Superior, continuous heating |

| Operational Speed | Fast cooling, easy tube replacement | Slower cooling, more downtime |

| Sample Handling | Ideal for delicate or complex setups | Risk of damage during insertion/removal |

| Best For | Rapid processing, frequent changes | Maximum precision and uniformity |

Struggling to choose the right furnace for your lab? At KINTEK, we specialize in advanced high-temperature solutions tailored to your needs. Leveraging exceptional R&D and in-house manufacturing, we offer a diverse product line including Tube Furnaces, Muffle Furnaces, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your unique experimental requirements, whether you prioritize temperature uniformity or operational convenience. Let us help you optimize your processes—contact us today for expert advice and a customized solution!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide